Ultra-high molecular weight polyethylene micro-porous membrane and preparation method thereof

A technology of polyethylene microporous membrane and ultra-high molecular weight, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of affecting phase separation size, reducing production efficiency, and low temperature of quenching roll, and achieves Improve compression resistance and heat distortion temperature, improve production stability, and increase the effect of line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

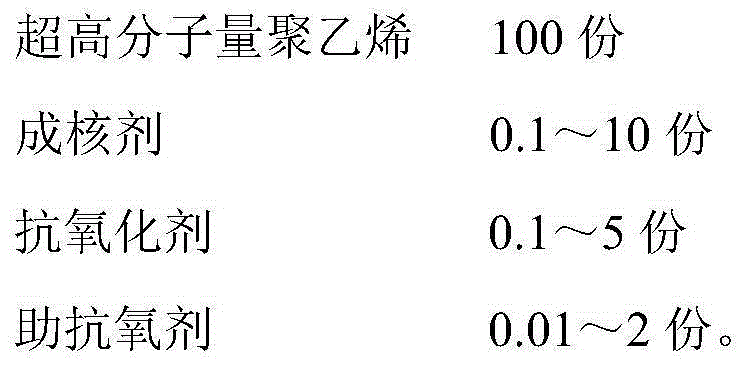

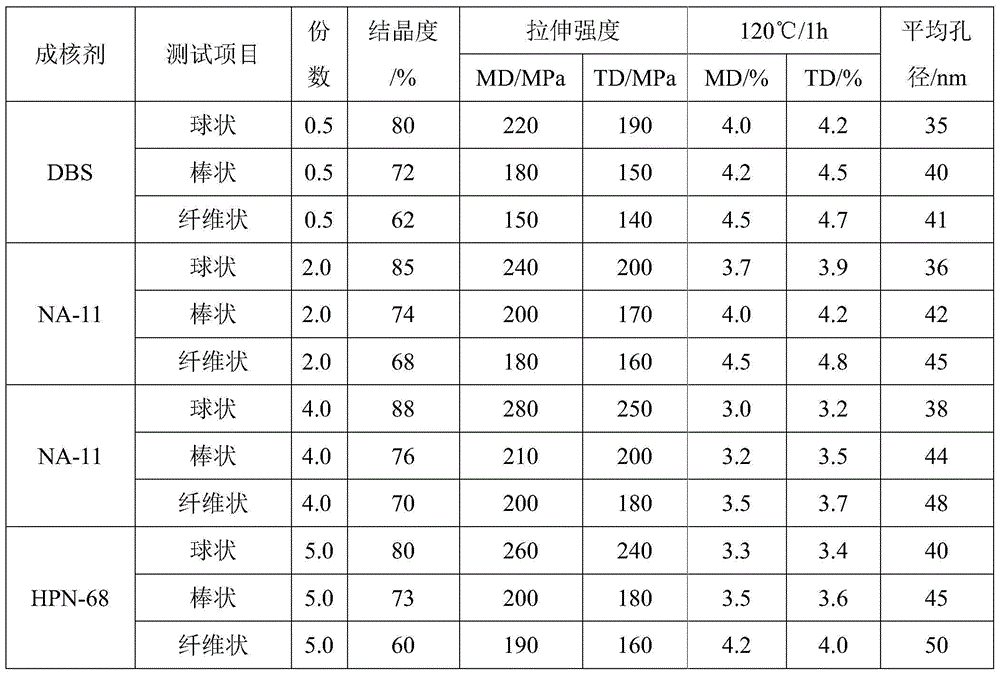

Method used

Image

Examples

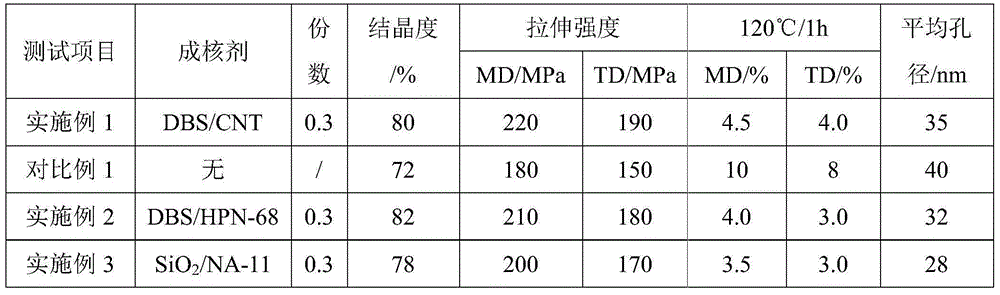

Embodiment 1

[0034] According to 0.3 parts of nucleating agent DBS (1,3:2,4-dibenzylidene sorbitol) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Isooctanol ester), 0.05 parts of auxiliary antioxidant (pentaerythritol distearyl diphosphite) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture A. Add the above-mentioned mixed solution A and the dried UHMWPE powder into the first extruder at a ratio of 235 parts: 100 parts, and blend them uniformly under high temperature and strong shear.

[0035] According to 0.3 part of nucleating agent CNT (carbon nanotube) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate), 0.05 part of auxiliary antioxidant Agent (pentaerythritol distearyl diphosphite) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture B. Add the above-mentioned mixed solution B and the dried UHMWPE powder into the second extruder at a ratio of 235 parts: 10...

Embodiment 2

[0040] According to 0.3 parts of nucleating agent DBS (1,3:2,4-dibenzylidene sorbitol) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Isooctanol ester), 0.05 parts of auxiliary antioxidant (pentaerythritol distearyl diphosphite) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture A. Add the above-mentioned mixed solution A and the dried UHMWPE powder into the first extruder at a ratio of 235 parts: 100 parts, and blend them uniformly under high temperature and strong shear.

[0041] According to 0.3 parts of nucleating agent HPN-68 (1,3:2,4-dibenzylidene sorbitol) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) ) Isooctyl propionate), 0.05 parts of co-antioxidant (pentaerythritol distearyl diphosphite) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture B. Add the above-mentioned mixed solution B and the dried UHMWPE powder into the second extruder at a ratio of 235 ...

Embodiment 3

[0044] According to 1 part of nucleating agent SiO 2 (Silica) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate), 0.05 parts of auxiliary antioxidant (pentaerythritol diphosphite) Stearyl alcohol ester) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture A. Add the above-mentioned mixed solution A and the dried UHMWPE powder into the first extruder at a ratio of 235 parts: 100 parts, and blend them uniformly under high temperature and strong shear.

[0045] According to 1 part of nucleating agent NA-11 (1,3:2,4-dibenzylidene sorbitol) and 1 part of antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) ) Isooctyl propionate), 0.05 parts of co-antioxidant (pentaerythritol distearyl diphosphite) and 233 parts of paraffin oil are blended in the ultrasonic generator to form a mixture B. Add the above-mentioned mixed solution B and the dried UHMWPE powder into the second extruder at a ratio of 235 parts: 100 parts, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com