Micro silicon-based capillary pump loop cooler

A technology of capillary pump and cooler, which is applied in the field of silicon-based capillary pump circuit micro-cooler, can solve the problems of thermal stress concentration, reduce heat dissipation efficiency, etc., and achieve the effects of promoting heat dissipation and cooling, reducing flow resistance of working fluid, and eliminating hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The silicon-based CPL micro-cooler of the present invention is combined with heat-resistant borosilicate glass and silicon chips through electrostatic bonding. Among them, microchannels, micro-rib array capillary structures, and liquid storage chambers are etched on the side where the silicon wafer contacts the borosilicate glass, and vacuum / liquid injection is processed on the borosilicate glass wafer at the position corresponding to the silicon wafer. hole.

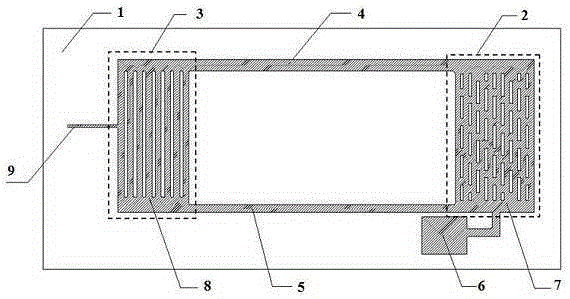

[0037] The semiconductor silicon chip structure that constitutes the silicon-based CPL microcooler is as follows: figure 1 As shown, the evaporator 2, the condenser 3, the vapor phase channel 4, the liquid phase channel 5 and the liquid storage tank 6 are etched on one side of the silicon wafer 1 by the MEMS etching process, and the evaporator contains a rectangular micro-rib array capillary structure 7. The condenser contains microchannels 8 and liquid injection channels 9, and the etched parts are marked with ...

Embodiment 2

[0043] For the evaporator of the capillary pump loop, in addition to the micro-rib array capillary structure described in Embodiment 1, it can also be figure 2 A microchannel array structure 10 similar to a condenser is shown. and figure 1 The etched structure of the silicon wafer shown is similar, and the hydraulic diameters of the vapor phase channel, liquid phase channel, condenser and evaporator microchannels are 320 μm, 285.7 μm, 267.7 μm and 218.2 μm, respectively.

Embodiment 3

[0045] In this embodiment, the vapor phase passage 4 and the liquid phase passage 5 of the capillary pump circuit microcooler described in Embodiment 1 and Embodiment 2 are subjected to variable cross-section processing, so that the cross-sectional area of the vapor phase passage is from the evaporator to the condenser. It increases linearly, the channel width increases from 600 μm to 1200 μm, and the corresponding channel hydraulic diameter increases from 300 μm to 342.9 μm; while the cross-sectional area change of the liquid phase channel is just opposite to that of the vapor phase channel, and it is linear from the evaporator to the condenser Decreasing the change, the channel width decreases from 700 μm to 300 μm, and the corresponding channel hydraulic diameter decreases from 311.1 μm to 240 μm. After the above adjustments, it is beneficial to enhance the spontaneous movement effect of the cooling working medium in the vapor phase channel and the liquid phase channel, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com