A nanofiber composite tow for reducing phenol content in flue gas and its preparation method and application

A technology of nanofibers and composite tows, applied in the direction of cellulose/protein conjugated artificial filaments, applications, fiber treatment, etc., can solve the problem of inability to reflect the characteristics of fiber materials, nanofiber specific surface area, reduce tar content, low efficiency, etc. problem, to achieve the effect of green and environmental protection of the preparation method, reduction of phenol content, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 20g of cellulose diacetate and 5g of diphenylmethane diisocyanate in 200mL of dimethylformamide, and react at 50°C for 2.0h to obtain a reaction liquid; Tin was added to the reaction solution, and the reaction was continued at 90° C. for 1.5 h to obtain cyclodextrin-modified cellulose acetate.

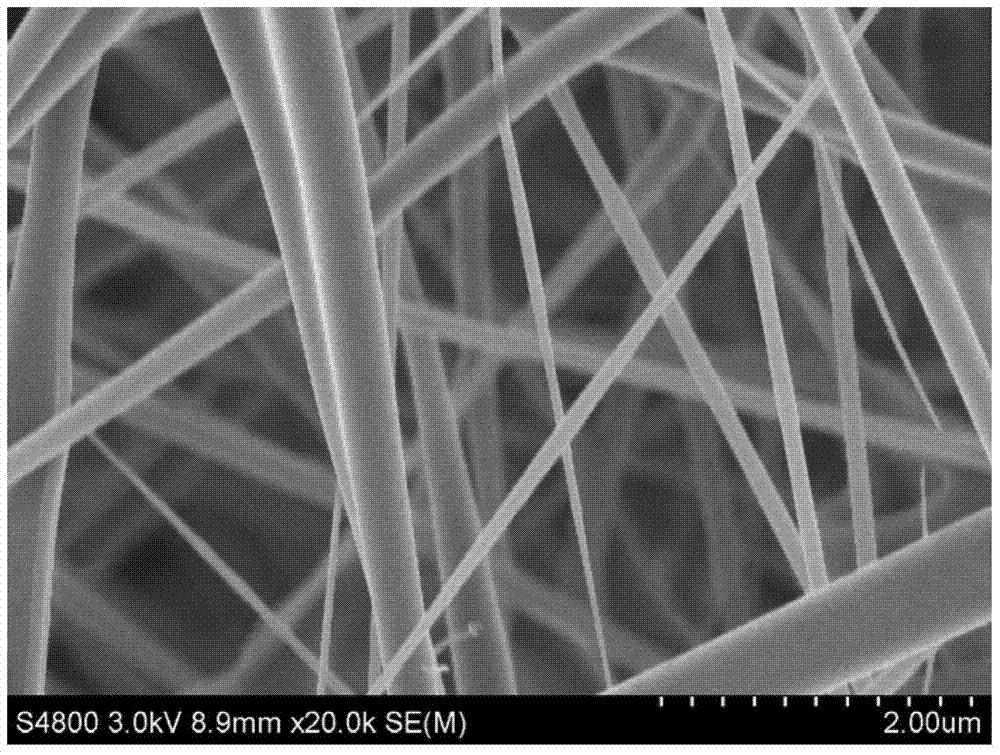

[0042] Cyclodextrin-modified cellulose acetate, cellulose diacetate, glycerol triacetate and N,N-dimethylformamide with a mass ratio of 0.005:0.01:0.001:1 were prepared into a uniform spinning solution, and the spinning The liquid is placed in the liquid-carrying tank of the needleless electrospinning machine, and the electrospinning is carried out at a voltage of 30kV. The winding speed of the base material is 400m / min, and the nanofibers are deposited on the surface of the tobacco tow to obtain a nanofiber composite tow. The diameter of the nanofiber in the nanofiber composite tow is 500nm.

[0043]The obtained nanofiber composite tow was rolled into a filter rod on ...

Embodiment 2

[0045] Dissolve 10g of cellulose acetate and 10g of toluene diisocyanate in 200mL of dimethylformamide, and react at 25°C for 0.5h to obtain a reaction liquid; add 15g of α-cyclodextrin and 0.1g of potassium acetate to the reaction solution, and continue to react at 30°C for 0.5h to obtain cyclodextrin-modified cellulose acetate.

[0046] Cyclodextrin-modified cellulose acetate, cellulose triacetate, ethylene glycol and acetone with a mass ratio of 0.05:0.2:0.01:2 are prepared into a uniform spinning solution, and the spinning solution is placed in a needle-free electrospinning machine In the carrier liquid tank, electrospinning at a voltage of 5kV, the distance between the steel wire and the tobacco tow substrate is adjusted to 5cm, the winding speed of the tobacco tow substrate is 50m / min, and the nanofibers are deposited on the tobacco tow. The surface of the bundle is obtained to obtain a nanofiber composite tow, and the diameter of the nanofiber in the nanofiber composite...

Embodiment 3

[0049] Dissolve 15g of cellulose triacetate and 7.5g of hexamethylene diisocyanate in 200mL of dimethylformamide, and react at 50°C for 2.0h to obtain a reaction liquid; Tin acid was added to the reaction solution, and the reaction was continued at 70° C. for 1.5 h to obtain cyclodextrin-modified cellulose acetate.

[0050] Cyclodextrin-modified cellulose acetate, cellulose diacetate, glycerol triacetate and N,N-dimethylformamide with a mass ratio of 0.01:0.01:0.001:2 were prepared into a uniform spinning solution, and the spinning The liquid is placed in the liquid-carrying tank of the needleless electrospinning machine, and the electrospinning is carried out at a voltage of 30kV. The distance between the steel wire and the tobacco tow substrate is adjusted to 20cm, and the winding speed of the tobacco tow substrate is 150m. / min, the nanofibers are deposited on the surface of the tobacco tow to obtain the nanofiber composite tow, and the diameter of the nanofiber in the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com