Method for controllable growing of two-dimensional chalcogen compound atomic-scale film on metal substrate

A technology of chalcogenides and metal substrates, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of poor controllability, difficulty in obtaining high-quality two-dimensional chalcogenide atomic-level thin films on a large scale, Discontinuity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

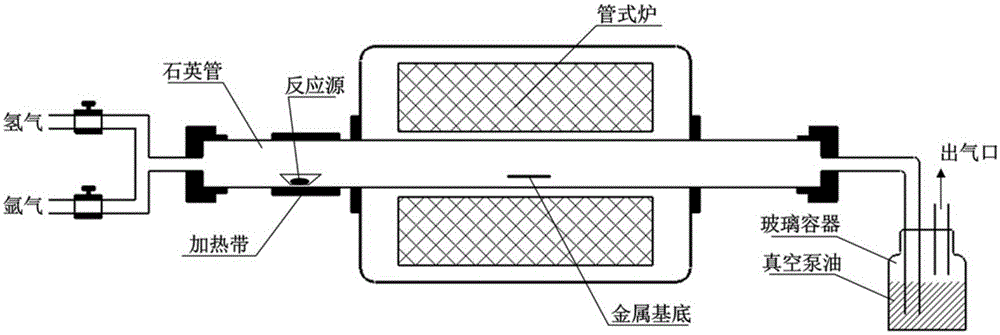

[0024] A method for preparing an atomic-level chalcogen compound film by chemical vapor deposition, comprising the following preparation steps:

[0025] (1) The molybdenum foil substrate with a thickness of 20 microns is first annealed at 1400 degrees for more than 10 hours in a hydrogen environment with a flow rate of 50sscm;

[0026] (2) Cut the annealed molybdenum foil into 3.5×2.5cm 2 The small piece is placed in a quartz tube furnace;

[0027] (3) Weigh 0.5 gram of sulfur powder, put it into the front end of the quartz tube, where it is heated with a heating tape;

[0028] (4) Seal the two ends of the quartz tube and vacuumize for 20 minutes to get rid of the remaining oxygen in the pipeline;

[0029] (5) After connecting one end of the quartz tube with the silicone tube, seal it with vacuum pump oil;

[0030] (6) Open the valve of the argon cylinder, inject argon into the quartz tube, and make its flow rate be 10 sccm;

[0031] (7) Turn on the tube furnace temperatur...

Embodiment 2

[0039] A method for preparing an atomic-level chalcogen compound film by chemical vapor deposition, comprising the following preparation steps:

[0040] (1) The molybdenum foil substrate with a thickness of 20 microns is first annealed at 1400 degrees for more than 10 hours in a hydrogen environment with a flow rate of 50sscm;

[0041] (2) Cut the annealed molybdenum foil into 3.5×2.5cm 2 The small piece is placed in a quartz tube furnace;

[0042] (3) Weigh 0.5 gram of sulfur powder, put it into the front end of the quartz tube, where it is heated with a heating tape;

[0043] (4) Seal the two ends of the quartz tube and vacuumize for 20 minutes to get rid of the remaining oxygen in the pipeline;

[0044] (5) After connecting one end of the quartz tube to the silicone tube, seal it with vacuum pump oil;

[0045] (6) Open the valve of the argon cylinder, inject argon into the quartz tube, and make its flow rate be 10 sccm;

[0046] (7) Turn on the tube furnace temperature ...

Embodiment 3

[0054] A method for preparing an atomic-level chalcogen compound film by chemical vapor deposition, comprising the following preparation steps:

[0055] (1) The molybdenum foil substrate with a thickness of 20 microns is first annealed at 1400 degrees for more than 10 hours in a hydrogen environment with a flow rate of 50sscm;

[0056] (2) Cut the annealed molybdenum foil into 3.5×2.5cm 2 The small piece is placed in a quartz tube furnace;

[0057] (3) Weigh 0.5 gram of selenium powder, put into the front end of quartz tube, use heating band to heat in this place;

[0058] (4) Seal the two ends of the quartz tube and vacuumize for 20 minutes to get rid of the remaining oxygen in the pipeline;

[0059] (5) After connecting one end of the quartz tube with the silicone tube, seal it with vacuum pump oil;

[0060] (6) open hydrogen and argon bottle valve, inject hydrogen and argon in quartz tube, make its flow rate be 2sccm and 18sccm;

[0061] (7) Turn on the tube furnace tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com