High-speed-extrudable wrought magnesium alloy and preparation method thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of metal materials and their processing, can solve the problems of low mechanical properties of magnesium alloys, achieve the effects of promoting dynamic recrystallization, improving corrosion resistance, and enhancing dynamic precipitation response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

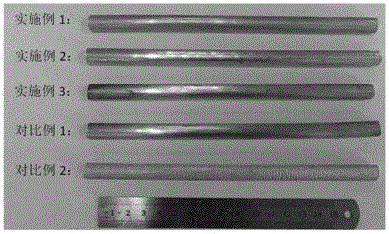

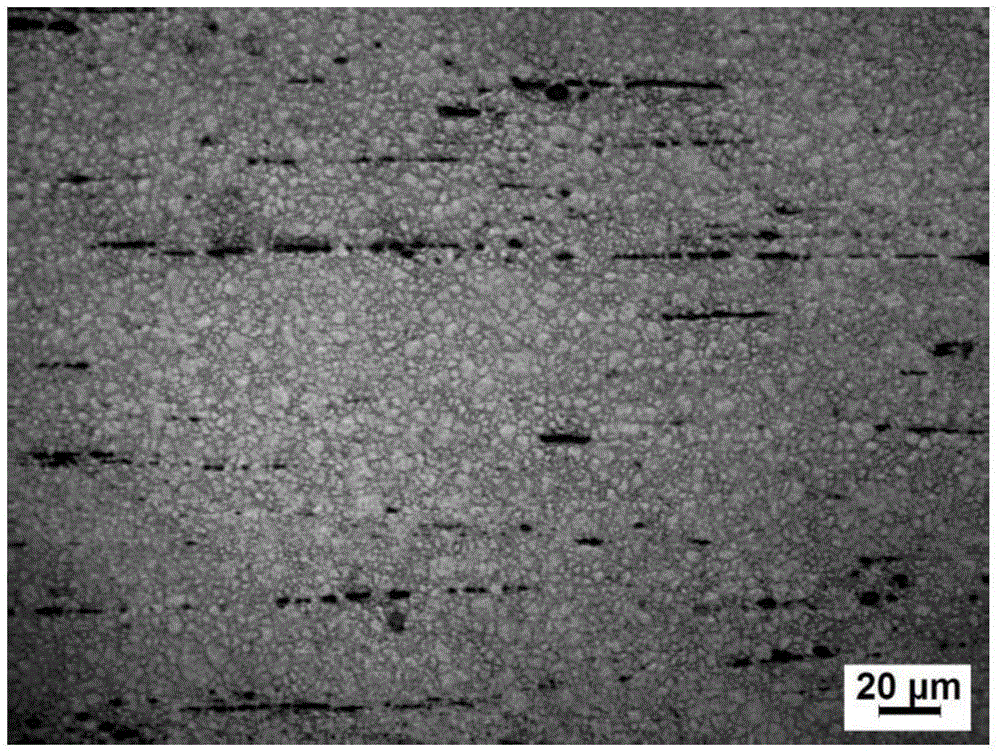

Embodiment 1

[0042] Design and select Mg-5.8Bi-3.0Al-1.2Zn-0.2Mn (wt%), and form a magnesium alloy according to the composition ratio (per 1000 grams of target alloy can be made of 40 grams of Mg-5Mn, 12 grams of Zn, 30 grams of Al, 58 1 gram Bi and 860 gram Mg are formulated), the preparation processing method comprises the following steps:

[0043] ① First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace and heat it so that the furnace temperature rises to 720°C at a heating rate of 20-40°C / min .

[0044] ② After the pure magnesium ingots are completely melted, add pure bismuth, pure aluminum, pure zinc and Mg-5Mn master alloy preheated to about 200°C, and raise the furnace temperature to 750°C, and keep it warm for about 10-20 minutes.

[0045] ③ After all the raw materials in step 2) are melted, stir for 2-5 minutes, adjust the furnace temperature to 720° C., keep the temperature for 8-10 minutes, so th...

Embodiment 2

[0051] The design selects Mg-7.0%Bi-2.0%Al-1.0%Zn-0.3%Mn, and forms magnesium alloy according to composition ratio (every 1000 grams of target alloy can be made of 60 grams of Mg-5Mn master alloy, 10 grams of pure Zn, 20 grams Pure Al, 70 grams of pure Bi and 840 grams of pure Mg are formulated), the preparation processing method comprises the following steps:

[0052] ① First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace and heat it so that the furnace temperature rises to 720°C at a heating rate of 20-40°C / min .

[0053] ② After the pure magnesium ingots are completely melted, add pure bismuth, pure aluminum, pure zinc and Mg-5Mn master alloy preheated to about 200°C, and raise the furnace temperature to 750°C, and keep it warm for about 10-20 minutes.

[0054] ③ After all the raw materials in step 2) are melted, stir for 2-5 minutes, adjust the furnace temperature to 720° C., keep the tem...

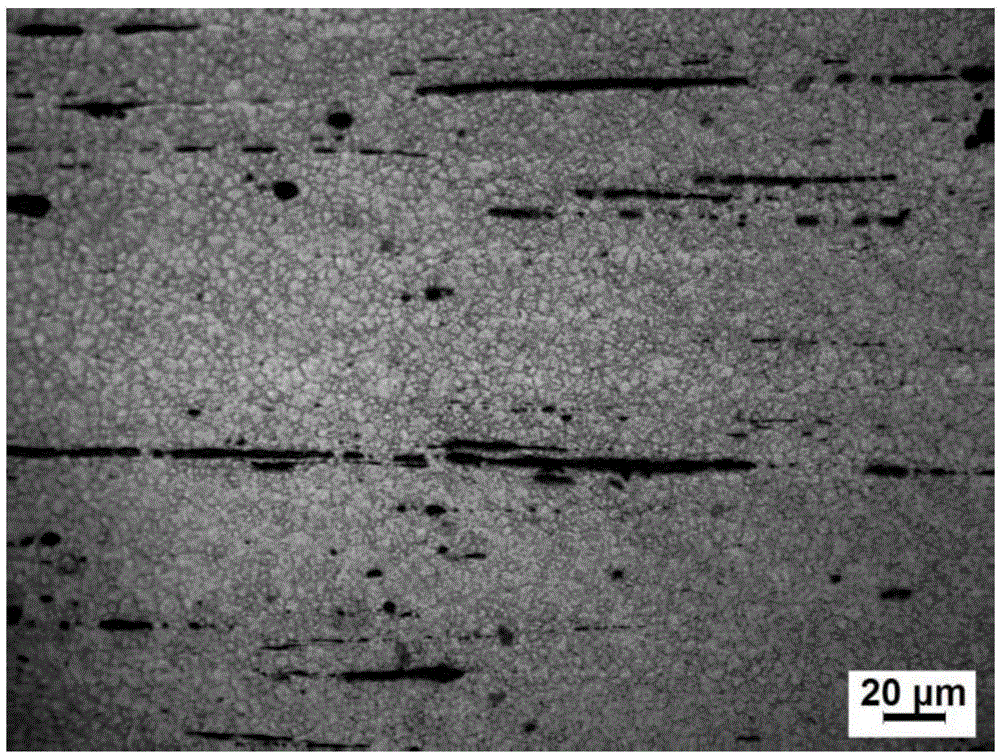

Embodiment 3

[0060] The design selects Mg-8.0%Bi-1.0%Al-1.0%Zn-0.3%Mn, and forms magnesium alloy according to composition ratio (every 1000 grams of target alloy can be made of 40 grams of Mg-5Mn master alloy, 10 grams of pure Zn, 10 grams Pure Al, 80 grams of pure Bi and 860 grams of pure Mg are formulated), the preparation processing method comprises the following steps:

[0061] ① First, clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, and heat it so that the furnace temperature rises to 720°C at a heating rate of 20-40°C / min .

[0062] ②After the pure magnesium ingots are completely melted, add pure bismuth, pure aluminum, pure zinc and Mg-5Mn intermediate alloy preheated to about 200°C, and raise the furnace temperature to 750°C, and keep it for about 10-20 minutes.

[0063] ③ After all the raw materials in step 2) are melted, stir for 2-5 minutes, adjust the furnace temperature to 720° C., keep the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com