Graphene-molybdenum oxide nano flame-retardant composite material

A composite material and nano-flame retardant technology, which is applied in the field of polymer flame retardant, can solve problems such as difficulty in ensuring the effect of flame retardant modification, and achieve the effects of easy scale-up production, wide application prospects, and easy addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

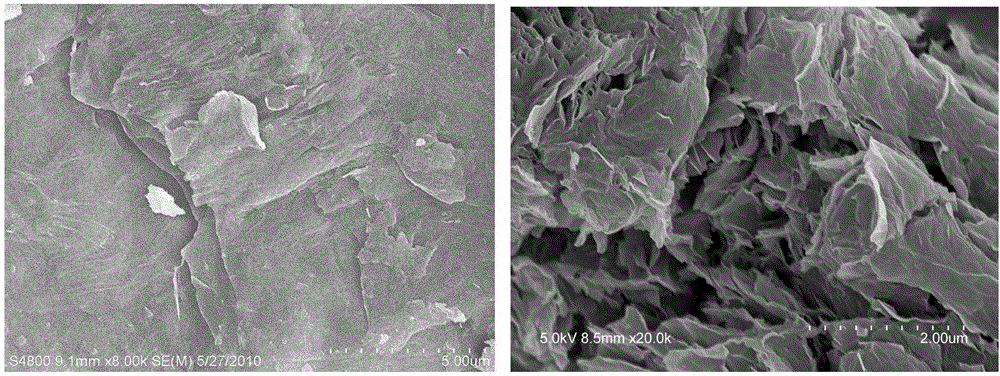

[0025] A kind of preparation of graphene-molybdenum oxide nano flame retardant composite material, comprises the following steps:

[0026] (1) 2 g of graphene oxide prepared by the Hummers method (see HummersWS, OffemanRE.Preparationofgraphiteoxide.JAmChemSoc, 1958, 80:1339 for the preparation method) was lyophilized into powder, and mixed with 16g of ammonium dimolybdate using a high-speed mixer Uniform;

[0027] (2) Utilize ball mill ball milling above-mentioned mixture to be graphene oxide-ammonium molybdate compound, the rotating speed of ball mill is 100rpm;

[0028] (3) Place the above compound in a tube furnace, heat up to 800°C at a heating rate of 10°C / min, keep it warm for 1min under nitrogen protection, and then lower it to room temperature to obtain a graphene-molybdenum oxide nanocomposite;

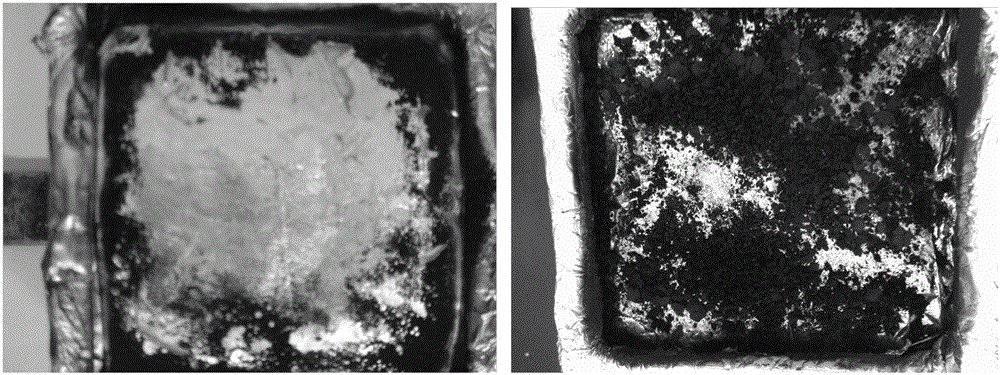

[0029] (4) Put the graphene-molybdenum oxide nanocomposite prepared in step (3) and general-purpose polystyrene resin (PG383, Taiwan Chi Mei Company) into the torque rheomet...

Embodiment 2

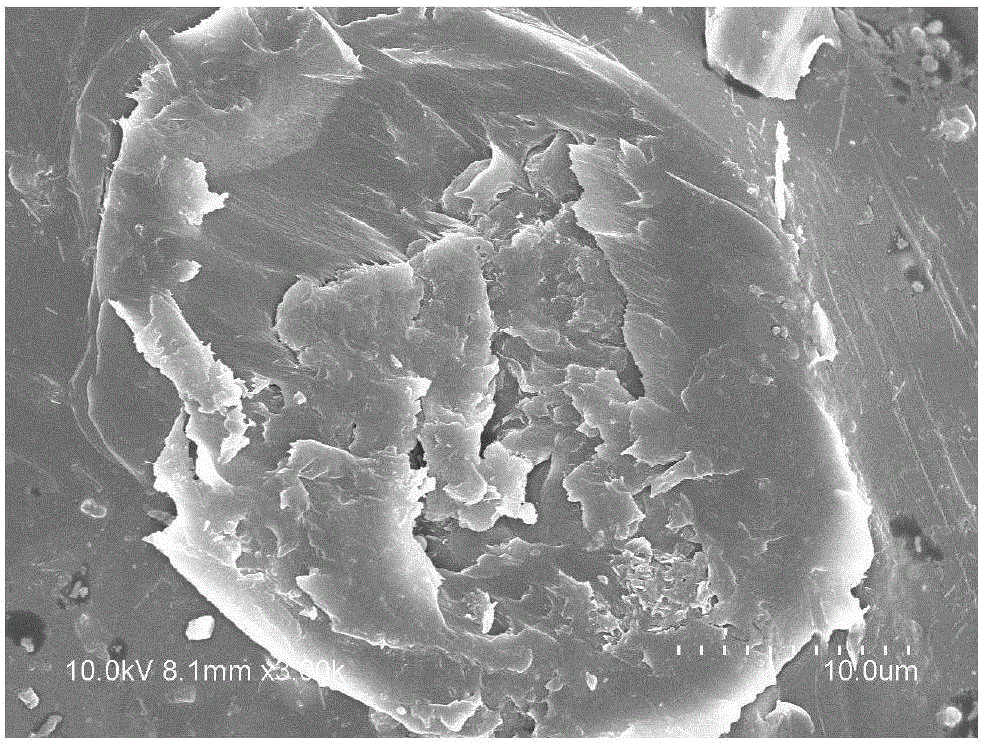

[0037]A kind of preparation method of graphene-molybdenum oxide nano flame retardant composite material, its difference with embodiment 1 is that the quality of graphene oxide powder becomes 4g by 2g, and 16g ammonium dimolybdate becomes 16g ammonium heptamolybdate , the speed of the ball mill changed from 100rpm to 120rpm, the heating rate changed from 10°C / min to 8°C / min, the heating temperature changed from 800°C to 500°C, and the holding time changed from 1min to 10min, the graphene-molybdenum oxide nanocomposite The number of parts by mass changed from 5 parts to 3 parts, and the number of parts by mass of the resin changed from 95 parts to 97 parts.

Embodiment 3

[0039] A kind of preparation method of graphene-molybdenum oxide nano flame retardant composite material, its difference with embodiment 1 is that the quality of graphene oxide powder becomes 10g by 2g, and 16g ammonium dimolybdate becomes 10g ammonium tetramolybdate , the speed of the ball mill was changed from 100rpm to 150rpm, the heating rate was changed from 10°C / min to 5°C / min, the heating temperature was changed from 800°C to 400°C, and the holding time was changed from 1min to 30min, the graphene-molybdenum oxide nanocomposite The number of parts by mass is changed from 5 parts to 8 parts, and the number of parts by mass of resin is changed from 95 parts to 92 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com