Method for preparation of water-soluble luminous graphite-phase carbon nitride nano kelp

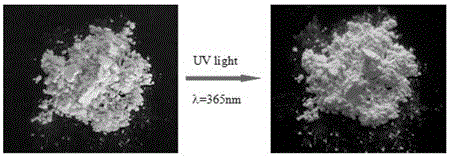

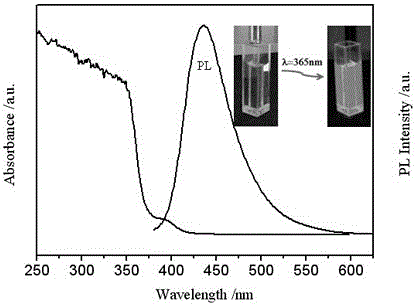

A graphitic carbon nitride, water-soluble technology, applied in chemical instruments and methods, nanotechnology, luminescent materials, etc., can solve the problems of poor material dispersibility, complicated steps and long time in the preparation method, and achieve the preparation method. Simple, stable luminescence, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of water-soluble luminous graphite phase carbon nitride nano-kelp, the specific steps are as follows:

[0025] Take 8.0 grams of dicyandiamide and add it to 15.2 grams of mixed salt of zinc chloride and potassium chloride with a molar ratio of 1:1.5, grind it thoroughly, and transfer it to a crucible.

[0026] At room temperature, put the crucible in a muffle furnace, feed nitrogen, raise the temperature to 600°C at a rate of 5°C / min, then raise the temperature to 700°C at a rate of 10°C / min, keep it for 2 hours, and then cool to room temperature; Solid frit.

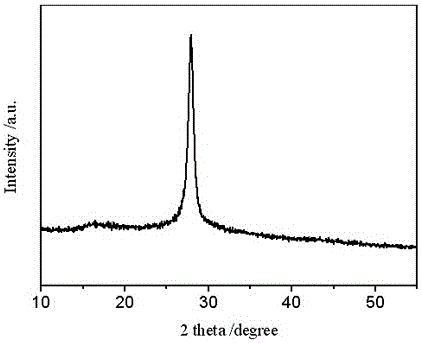

[0027] Grind the obtained solid frit, add 0.25M dilute hydrochloric acid and stir to form a suspension evenly, and centrifuge the suspension to obtain graphite phase carbon nitride nano-kelp precipitate, then wash it with dilute hydrochloric acid for 5 times, and then use deionized Washed with water, freeze-dried to obtain light yellow powder, identified by XRD, the product is graphite phase...

Embodiment 2

[0029] A preparation method of water-soluble luminous graphite phase carbon nitride nano-kelp, the specific steps are as follows:

[0030] Take 8.0 grams of melamine and add it to 33.6 grams of mixed salt of sodium chloride and potassium chloride with a molar ratio of 1:1.2, grind it thoroughly, and then transfer it to a crucible.

[0031] At room temperature, the temperature was raised to 670°C at a rate of 5°C / min, kept for 2 hours, and then cooled to room temperature at a rate of 3°C / min to obtain a light yellow solid frit.

[0032] The obtained light yellow solid frit was ground, added 0.03M dilute hydrochloric acid, stirred for 30 minutes to obtain a suspension, and the obtained suspension was centrifuged to obtain a graphite phase carbon nitride nano-kelp precipitate, which was then washed with dilute hydrochloric acid for 5 times, and then washed with deionized water, freeze-dried to obtain graphitic carbon nitride nano-kelp.

Embodiment 3

[0034] A preparation method of water-soluble luminous graphite phase carbon nitride nano-kelp, the specific steps are as follows:

[0035] Take 16.0 grams of urea and add it to 18.2 grams of mixed salt of sodium chloride and lithium chloride with a molar ratio of 1:0.7, grind it thoroughly, and transfer it to a crucible.

[0036] At room temperature, the crucible was placed in a muffle furnace, fed with nitrogen, heated to 600°C at a rate of 5°C / min, kept for 1 hour, and then cooled to room temperature to obtain a solid frit.

[0037] The obtained solid frit was ground, added 0.2M dilute hydrochloric acid, stirred evenly to obtain a suspension, and the obtained suspension was centrifuged to obtain a graphite phase carbon nitride nano-kelp precipitate, which was then washed 5 times with dilute hydrochloric acid, and the The precipitate is dispersed in water for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com