Subway internal steel frame casting and production technology thereof

A production process and casting technology, which is applied in the field of steel frame castings in subways and its production process, can solve the problems of small difference in strength, high acceptance standards, insufficient pouring, etc., and achieve the effect of reducing hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Process parameters: the shrinkage rate is all 2%.

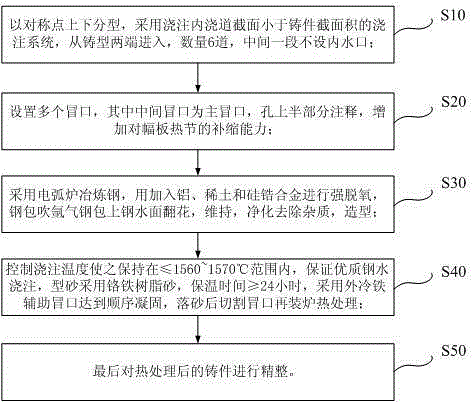

[0038] Parting surface: The upper and lower parts are divided into symmetrical points, which is conducive to mold taking and convenient modeling. However, due to the reduced strength of the thin-walled model, it is not conducive to mass production, so the model with a bottom plate is adopted.

[0039] Gating system: The cross-section of the inner runner is smaller than the cross-sectional area of the casting. Enter from both ends of the mold, the number is 6, and there is no inner nozzle in the middle section.

[0040] Riser setting: the middle riser is the main riser, and the upper half of the hole is injected to increase the feeding capacity of the hot joint of the web. The air outlet riser is set on the rib plate, and the auxiliary rib plate is solidified at the same time. A number of small risers are placed at the hot joint of the crosshead. Ensure that each small hot spot is cast densely.

[0041] Anti-crack...

Embodiment 2

[0049] Process parameters: The shrinkage rate of the longer beam is 1.8% in the length direction, and the remaining 2%. All other accessories are 2%.

[0050] Parting surface: The upper and lower parts are divided into symmetrical points, which is conducive to mold taking and convenient modeling. However, due to the reduced strength of the thin-walled model, it is not conducive to mass production, so the model with a bottom plate is adopted.

[0051] Gating system: The cross-section of the inner runner is smaller than the cross-sectional area of the casting. Enter from both ends of the mold, the number is 6, and there is no inner nozzle in the middle section.

[0052] Riser setting: the middle riser is the main riser, and the upper half of the hole is injected to increase the feeding capacity of the hot joint of the web. The air outlet riser is set on the rib plate, and the auxiliary rib plate is solidified at the same time. A number of small risers are placed at the hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com