Preparation method for surface molecular imprinting nano-composite material of magnetic graphene

A nanocomposite material, surface molecular imprinting technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of cumbersome process, time-consuming and other problems, and achieve environmental friendliness and simple operation. Time-consuming, fast mass transfer results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

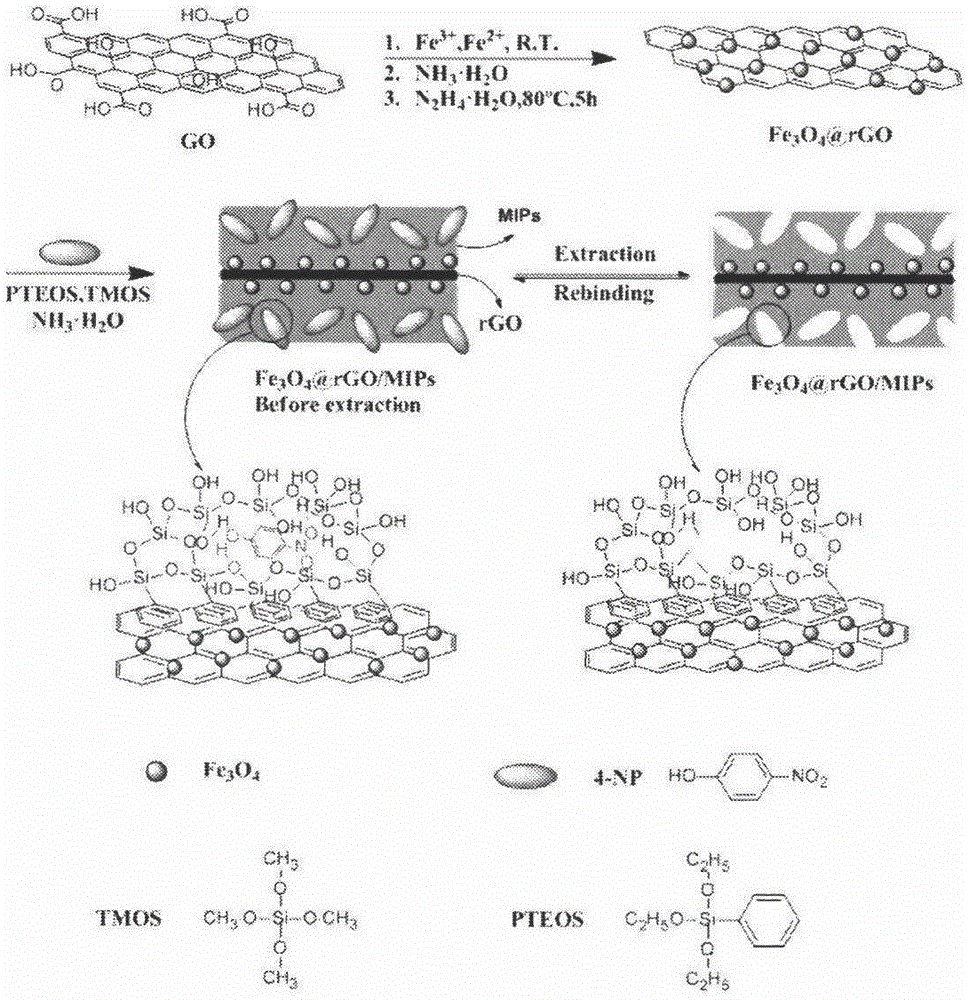

Method used

Image

Examples

Embodiment 1

[0017] 500mg of graphene oxide was dispersed in 250ml of deionized water and ultrasonicated for 1h. 0.01molFeCl 3 ·6H 2 O and 0.075mol FeCl 2 4H 2 O was dissolved in 25ml deionized water, and then the above solution was dropped into the GO aqueous solution drop by drop, and N 2 , stirred for 1h. Add 28% ammonia water dropwise to adjust the pH of the solution to 9.5. Add 5ml of hydrazine hydrate at 60°C and stir for 4 hours. After the solution was cooled to room temperature, it was suction filtered and washed with deionized water to obtain magnetic graphene. Take 50mg of magnetic graphene, add 200mg of p-nitrophenol, and 50ml of deionized water. Then, 10 mg of phenyltriethoxysilane and 10 mg of tetraethoxysiloxane were added to the above system, and then 28% ammonia water was added to adjust the pH to 9.5, and the mixture was shaken in a water bath for 8 hours at a frequency of 80 Hz. After the reaction, the product was washed with deionized water. Shake the product wit...

Embodiment 2

[0019] 800mg of graphene oxide was dispersed in 250ml of deionized water and ultrasonicated for 2h. 0.03molFeCl 3 ·6H 2 O and 0.01mol FeCl 2 4H 2 O was dissolved in 25ml deionized water, and then the above solution was dropped into the GO aqueous solution drop by drop, and N 2 , stirred for 2h. 28% ammonia water was added dropwise to adjust the pH of the solution to 10. 10 ml of sodium borohydride was added at 80° C., and the reaction was stirred for 7 h. After the solution was cooled to room temperature, it was suction filtered and washed with deionized water to obtain magnetic graphene. Take 50mg of magnetic graphene, add 50mg of 2,4-dichlorophenol, and 50ml of deionized water. Then, 20 mg of phenyltriethoxysilane and 10 mg of tetramethoxysiloxane were added to the above system, and then 28% ammonia water was added to adjust the pH to 11, and the mixture was shaken in a water bath for 10 h at a frequency of 120 Hz. After the reaction, the product was washed with deion...

Embodiment 3

[0021] 1250mg of graphene oxide was dispersed in 250ml of deionized water and ultrasonicated for 4h. 0.06molFeCl 3 ·6H 2 O and 0.02mol FeCl 2 4H 2 O was dissolved in 25ml deionized water, and then the above solution was dropped into the GO aqueous solution drop by drop, and N 2 , stirred for 0.5h. Add 28% ammonia water dropwise to adjust the pH of the solution to 11. Add 15 ml of hydrazine hydrate at 100° C., and stir for 10 h. After the solution was cooled to room temperature, it was suction filtered and washed with deionized water to obtain magnetic graphene. Take 50m magnetic graphene, add 20mg 2-picoline, 50ml deionized water. Then, 50 mg of 3-aminopropyltrimethoxysilane and 10 mg of tetramethoxysiloxane were added to the above system, and then 28% ammonia water was added to adjust the pH to 12, and the mixture was shaken in a water bath for 15 hours at a frequency of 180 Hz. After the reaction, the product was washed with deionized water. Shake the product with el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com