Preparation method for magnetic macromolecule nanoball

A polymer nanosphere and magnetic technology, which is applied in the preparation of microspheres, magnetic materials, magnetic objects, etc., can solve the problem of time-consuming, and achieve the effects of easy magnetic separation and recovery, good superparamagnetic properties, and saving time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

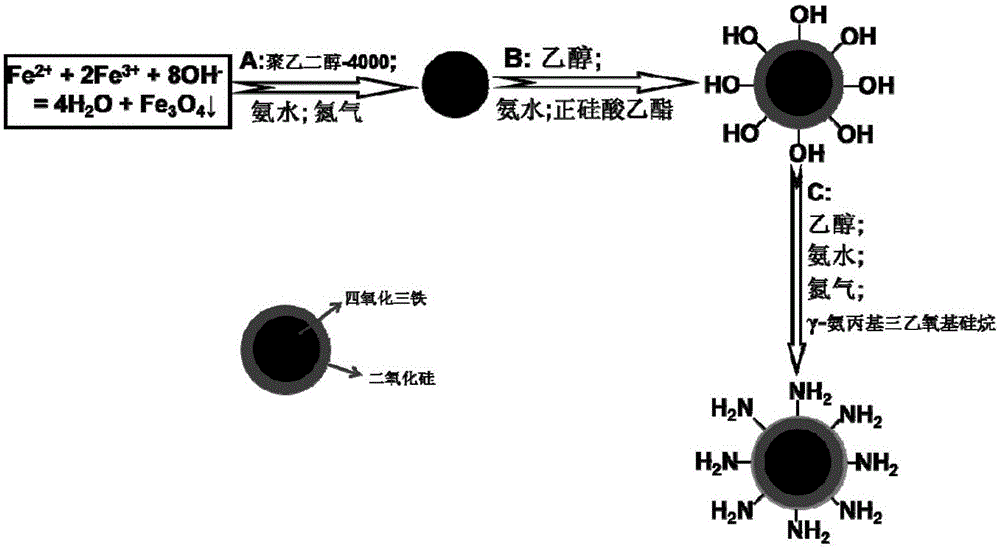

[0032] Continuous and rapid preparation of embodiment 1 magnetic polymer nanosphere

[0033] (1) High-performance magnetic nanospheres (ie Fe 3 o 4 Preparation of Nanoparticle Ferrofluid)

[0034] Fe 3 o 4 Nanoparticles are prepared by an improved chemical co-precipitation method, and the reaction formula is

[0035] Fe 2+ +2Fe 3+ +8OH - → Fe 3 o 4 +4H 2 o

[0036] Specific process: weigh 4.054g FeCl respectively 3 ·6H 2 O and 1.988gFeCl 2 4H 2 O (considering Fe 2+ Oxidation in the preparation and subsequent process, select Fe 3+ / Fe 2+ The amount ratio of the substance is 3 / 2) in a 50mL beaker, add 25mL secondary ion exchange water to dissolve, then add 90mL secondary ion exchange water and mix to form a 115mL mixed solution, add the mixed solution into a 500mL three-necked bottle, Nitrogen was passed through, mechanically stirred (rotating speed 1000rpm) in a water bath at 30°C for 5min, and a syringe (diameter 0.7mm) was added dropwise with a mass concentr...

Embodiment 2

[0041] Example 2 Characterization of magnetic polymer nanospheres

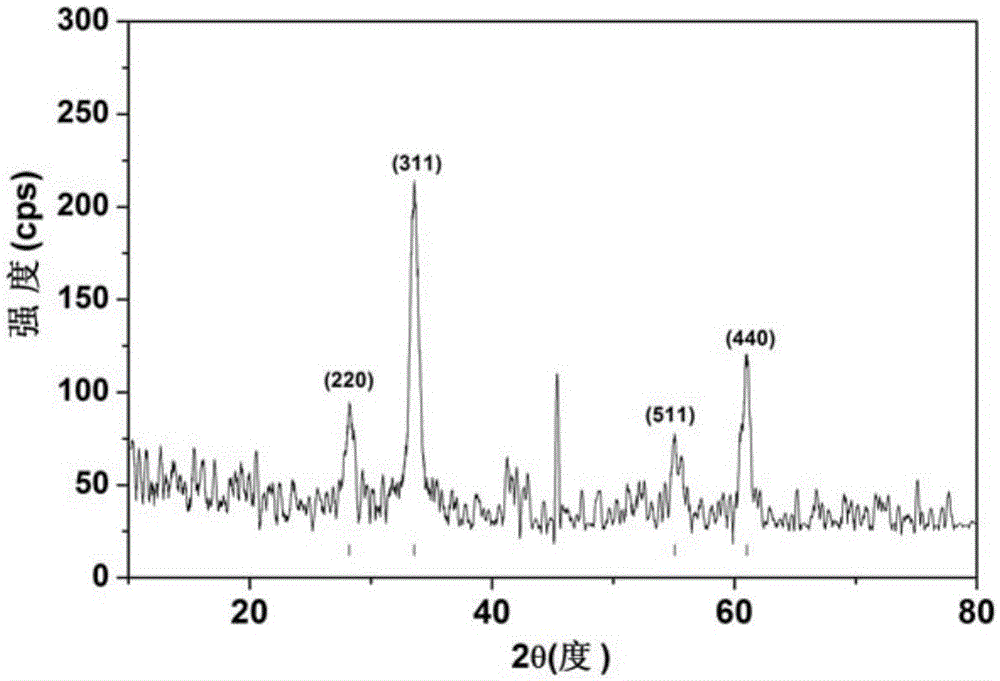

[0042] (1) X-ray diffraction analysis (XRD) of magnetic polymer nanospheres

[0043] figure 2 Middle diffraction peak position and intensity result are all consistent with the standard data of powder diffraction JCPDS card (#85-1436), show that the magnetic polymer nanosphere prepared by the method of Example 1 belongs to single-phase Fe 3 o 4 Spinel structure (cubic system). There are obvious diffraction peaks at 2θ of 30.1°, 35.4°, 57.0° and 62.6°. For (220), (311), (511) and (440) crystal planes respectively, comparing the PDF card, it can be seen that the main Composition is Fe 3 o 4 , and it can be seen that Fe 3 o 4 The cubic sharpstone structure, combined with the Scherer formula, can also approximate the particle size. The Scherer formula is expressed as formula (2):

[0044] D h k 1 = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume usage | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com