Inorganic polymer modification insoluble halogen-free flame retardant and preparation method and application thereof

A technology of inorganic polymers and flame retardants, applied in the field of inorganic polymer modified insoluble halogen-free flame retardants, halogen-free flame retardants, textile polyurethane coatings, ultrafine fiber synthetic leather, can solve the problem The water solubility and flame retardancy cannot meet the technical requirements of synthetic leather for flame retardants, reduce the flame retardant effect, and reduce the problem, so as to achieve the effect of small addition, excellent flame retardant effect, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

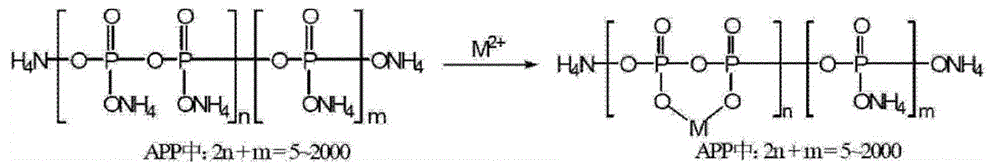

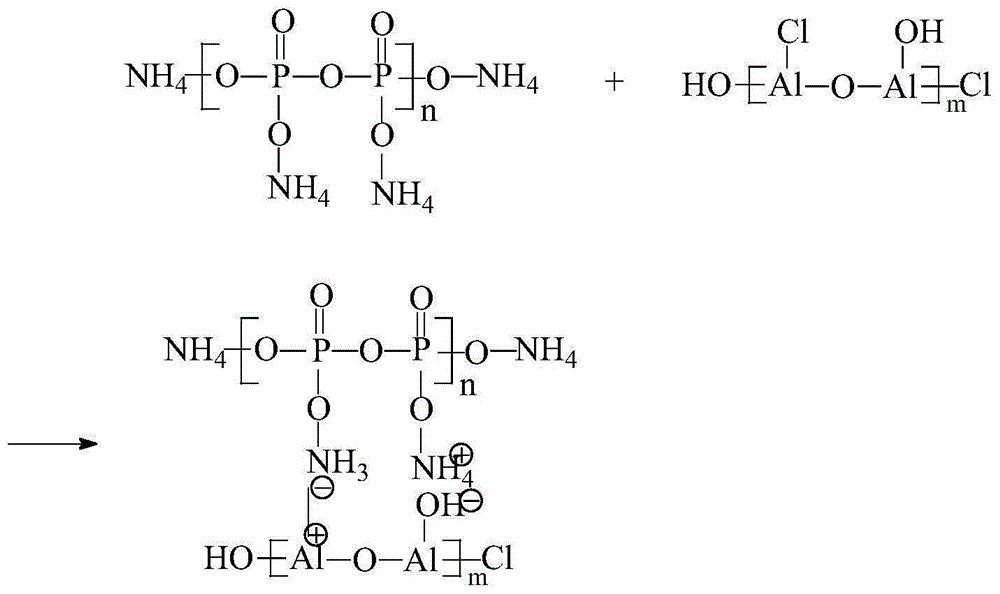

Method used

Image

Examples

Embodiment 1

[0021] 100g of water-soluble ammonium polyphosphate with a degree of polymerization of 20 was dissolved in 25°C to prepare a 30% aqueous solution, and 75g of polyaluminum sulfate was dissolved in 25°C water to prepare a 30% aqueous solution; the two solutions were mixed and kept at 25°C After stirring and reacting for 30 minutes, filter the resulting white precipitate, rinse the filter cake twice with clean water at room temperature and dry it in a blast drying oven at 100°C for 3 hours to obtain a white powder insoluble inorganic polymer halogen-free flame retardant The yield is 95%; the solubility in water at 25°C is less than 0.01g / 100ml, and the weight loss rate after boiling in hot water at 100°C for 2 hours is less than 0.11g / 100ml.

Embodiment 2

[0023] 100g of water-soluble ammonium polyphosphate with a degree of polymerization of 1000 is dissolved in water at 80°C to make a 30% aqueous solution, and 50g of white polyaluminum chloride is dissolved in water at 80°C to make a 50% solution; mix the two solutions , keep stirring and reacting at 80°C for 20min, filter the resulting white precipitate, wash the filter cake twice with clean water at room temperature and dry it in a blast drying oven at 100°C for 3 hours to obtain a white powdery insoluble inorganic polymer Halogen-free flame retardant; the yield is 93%, the solubility in water at 25°C is less than 0.01g / 100ml, and the weight loss rate after boiling in hot water at 100°C for 2 hours is less than 0.11g / 100ml.

Embodiment 3

[0025]100g of water-soluble ammonium polyphosphate with a degree of polymerization of 20 was dissolved in water at 50°C to make a 50% aqueous solution, and 100g of polyferric chloride was dissolved in water at 50°C to make a 30% solution; the two solutions were mixed and kept at 50 After stirring and reacting at ℃ for 40 minutes, the resulting tan precipitate was filtered, the filter cake was washed twice with clean water at room temperature and dried in a blast drying oven at 120 ℃ for 2 hours to obtain a tan powdery insoluble inorganic polymer Halogen flame retardant; the yield is 97%, the solubility in water at 25°C is less than 0.01g / 100ml, and the weight loss rate after boiling in hot water at 100°C for 2 hours is less than 0.10g / 100ml. Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com