Two-component modified polyurethane sustained or controlled release coating material with chelation function

A two-component modification and coating material technology, applied in fertilizer mixture, application, fertilization device and other directions, can solve the problems of high cost, soil is not easy to degrade, limited application scope, etc., achieve strong resistance to mechanical damage, improve phosphate fertilizer The effect of utilization rate and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

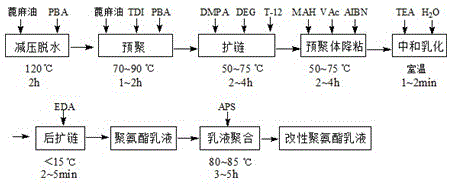

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A two-component modified polyurethane sustained and controlled release coating material with chelating function

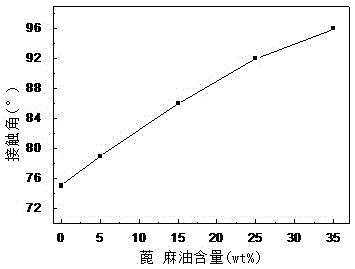

[0031] in N 2 Under protection, in a reaction vessel with a reflux condenser and a thermometer, add 45g of toluene diisocyanate (IPDI), polybutylene adipate diol (PBA) with a hydroxyl value equal to 55mgKOH / g after vacuum dehydration and 20g of castor oil with a hydroxyl value equal to 163mgKOH / g, react at a constant temperature of 90°C for 1.5h under mechanical stirring; cool down to 50°C, add 8.5g of dimethylolpropionic acid (DMPA), diethylene glycol ( DEG) 5.2g, 3 drops of dibutyltin dilaurate (T-12) and 1 drop of stannous octoate (T-9), continue the reaction at 60°C for 3h, add 0.05g of azobisisobutylcyanide (AIBN) ) of maleic anhydride (MHA) 15g, vinyl acetate (VAc) 10g, acrylic acid (AA) 10g, stir evenly, add triethylamine 6.4g under high shear force and neutralize for 1min, then stir successively under high speed Add 250g of deionized wat...

Embodiment 2

[0034] Example 2: A two-component modified polyurethane sustained and controlled release coating material with chelating function

[0035] in N 2 Under protection, in a reaction vessel with a reflux condenser and a thermometer, add 45g of isophorone diisocyanate (IPDI), polybutylene adipate diol with a hydroxyl value equal to 110mgKOH / g after vacuum dehydration (PBA) 50g and castor oil with a hydroxyl value equal to 163mgKOH / g 21g, react at a constant temperature of 85°C for 2h under mechanical stirring; cool down to 50°C, add 8.5g of dimethylolpropionic acid (DMPA), 3 drops of dibutyltin Laurate (T-12) and 1 drop of stannous octoate (T-9), continue to react at 70°C for 3.5h, cool down, add vinyl acetate (VAc) dissolved in 0.05g azobisisobutylcyanide (AIBN) 15g, 15g maleic anhydride (MHA), 15g acrylic acid (AA), stir evenly, add 7.4g triethylamine under high shear force for neutralization for 1min, then add 250g deionized water below 15℃ under high speed stirring , 50g of aq...

Embodiment 3

[0038] Example 3: A two-component modified polyurethane sustained and controlled release coating material with chelating function

[0039] in N 2 Under protection, in a reaction vessel with a reflux condenser and a thermometer, add 78g of diphenylmethane diisocyanate (MDI), and 50g of polyoxypropylene glycol (PPG) whose hydroxyl value after vacuum dehydration is equal to 110mgKOH / g, 20g of castor oil with a hydroxyl value equal to 163mgKOH / g was reacted at a constant temperature of 70°C for 1.5h under mechanical stirring; the temperature was lowered to 50°C, and 7.2g of dimethylolbutyric acid (DMBA) and 1,4-butanediol (BDO) were added ) 6.5g, heat up to 60°C and continue the reaction for 3.5h, add 15g of vinyl acetate (VAc) dissolved in 0.05g of benzoyl peroxide (BPO), 15g of maleic anhydride (MHA), 10g of acrylic acid (AA), and stir Evenly, add 6.4g of triethylamine under high shear force for neutralization for 1min, then add 250g of deionized water below 15℃ and 50g of aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com