Dielectric ceramics, and laminated ceramic capacitor

一种陶瓷电容器、陶瓷的技术,应用在叠层电容器、电容器、固定电容器等方向,能够解决介电常数降低、温度特性劣化、绝缘电阻降低等问题,达到介电损失小、耐电压性良好、良好温度特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

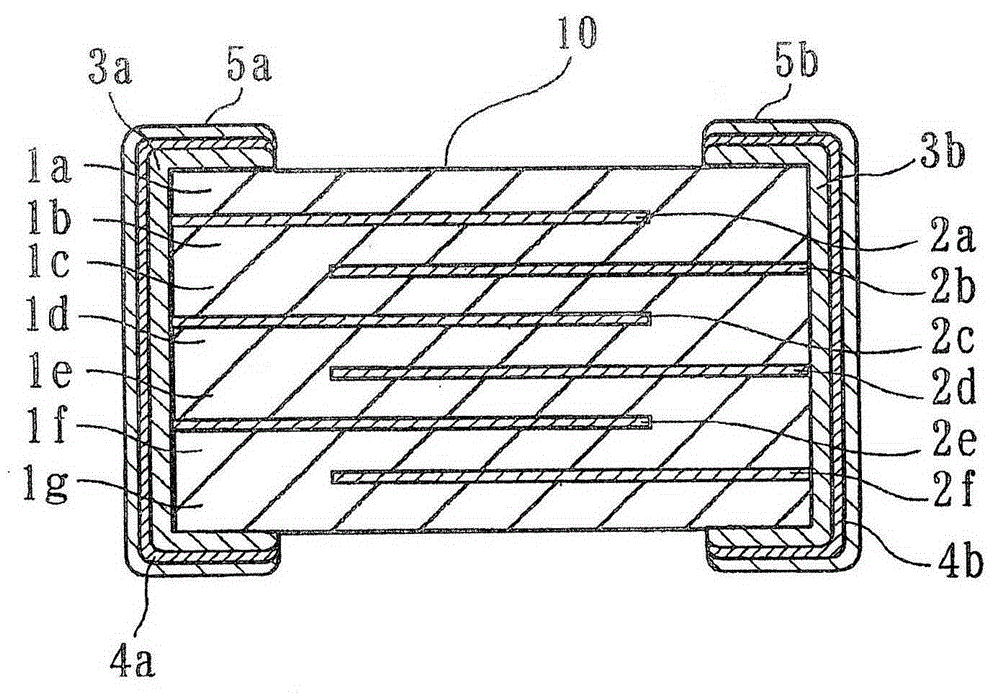

Image

Examples

Embodiment 1

[0102] [production of sample]

[0103] [Sample No. 1]

[0104] Prepare BaCO 3 、TiO 2 and NiO as ceramic raw materials, and weigh these ceramic raw materials so that the molar ratio m of Ba and Ti is 1.010, and relative to 100 mole parts of BaTiO 3 , the mole fraction a of NiO is 1.0.

[0105] Next, this weighed object was put into a ball mill together with PSZ balls and pure water, wet mixed and pulverized for 48 hours, and then calcined at a temperature of 1100° C. to produce a calcined powder.

[0106] Next, prepare Dy 2 o 3 , MnCO 3 , MgCO 3 and SiO 2 as an additive material. Then, these additive materials are weighed so that the dielectric ceramic satisfies the following general formula (B).

[0107] 100Ba 1.010 TiO 3 +1.0NiO+1.0DyO 3 / 2 +0.3MnO+1.0MgO+1.5SiO 2 ...(B)

[0108] Next, these additive materials were put into a ball mill together with the above-mentioned calcined powder, wet-mixed in the ball mill for 24 hours, and then evaporated and dried to obt...

Embodiment 2

[0148] [production of sample]

[0149] [Sample No. 11 to 18]

[0150] A ceramic raw material powder having the same composition as Sample No. 1 was produced to obtain a ceramic laminate.

[0151] Next, the ceramic laminate was subjected to a binder removal treatment at a temperature of 300° C., and further, after controlling the oxygen partial pressure to 10 -10 ~10 -12 H in MPa 2 -N 2 -H 2 In a reducing environment composed of O gas, firing treatment was performed on each sample at different temperatures in the range of 1140 to 1280° C. for about 2 hours to obtain multilayer ceramic capacitors with sample numbers 11 to 18.

[0152] [Sample No. 19-26]

[0153] Multilayer ceramic capacitors of sample numbers 19 to 26 having different firing temperatures were obtained by the same method and procedure as sample numbers 11 to 18 except that NiO was not added.

[0154] [Structural analysis of ceramic structure]

[0155] For each sample of sample numbers 11 to 26, the struct...

Embodiment 3

[0174] [production of sample]

[0175] Prepare BaCO 3 、TiO 2 and NiO as ceramic raw materials, and these ceramic raw materials are weighed so that the molar ratio m of Ba and Ti and relative to 100 mole parts of BaTiO 3 The mole fraction a of NiO was the value shown in Table 5, and the calcined powder was produced in the same method and procedure as in [Example 1].

[0176] Next, prepare R oxide containing rare earth element R (La 2 o 3 , CeO 2 、Pr 6 o 11 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 , Yb 2 o 3 、Lu 2 o 3 , Y 2 o 3 ), M oxides containing metal elements M (MnO, Fe 2 o 3 , CuO, CoO, V 2 o 5 、WO 3 、Cr 2 o 3 、MoO 2 、Al 2 o 3 ), MgO and SiO 2 as an additive material.

[0177] Next, these additive materials were weighed so that b, c, d, and e represented by the following general formula (C) of the dielectric ceramics had the values shown in Table 5.

[0178] 100Ba m TiO 3 +aNi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com