A low-carbon and low-silicon hot-rolled coil plate for mobile conveying pipe and its manufacturing method

A low-carbon, low-silicon, manufacturing method technology, applied in the field of pipeline steel, can solve the problems that cannot meet the requirements of comprehensive mechanical properties, surface quality and plate shape of the coil, and meet the requirements of anti-corrosion galvanizing, reduce Coriolis air mass, The effect of suppressing responses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

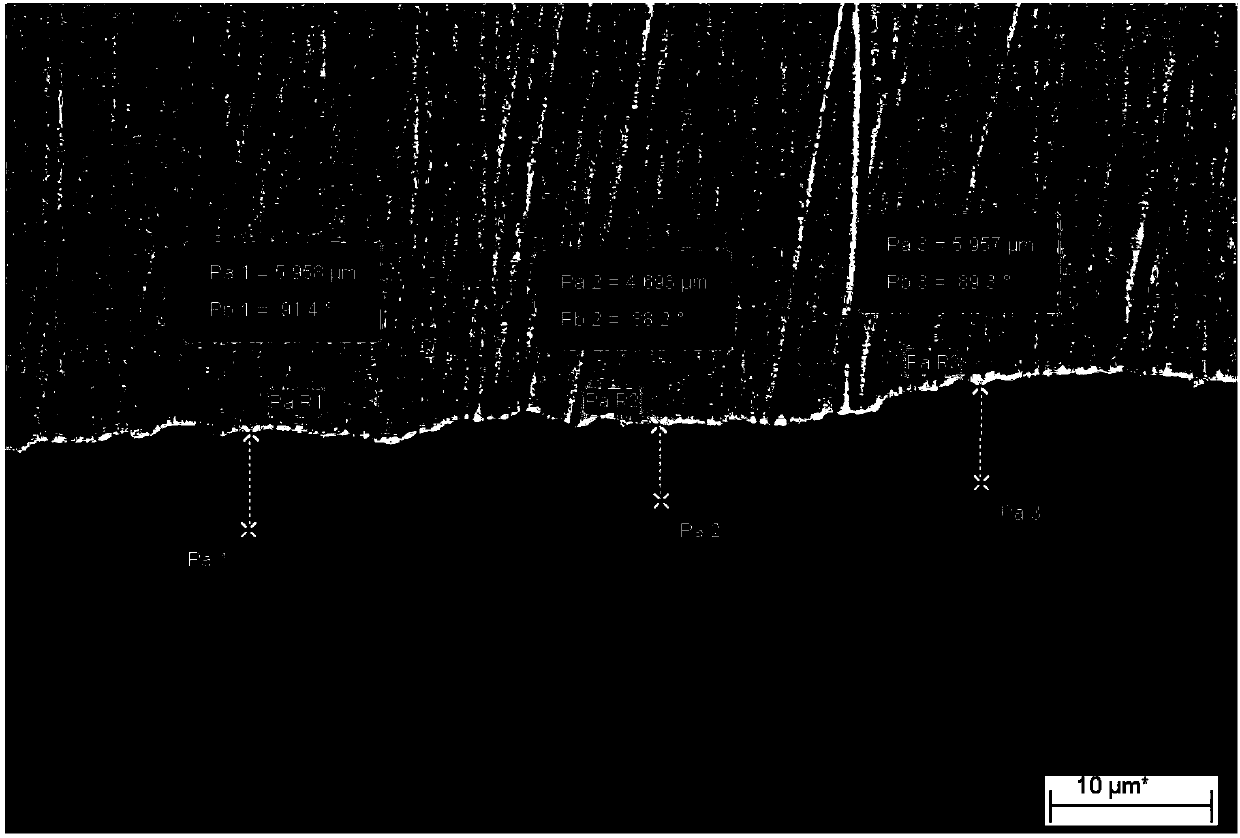

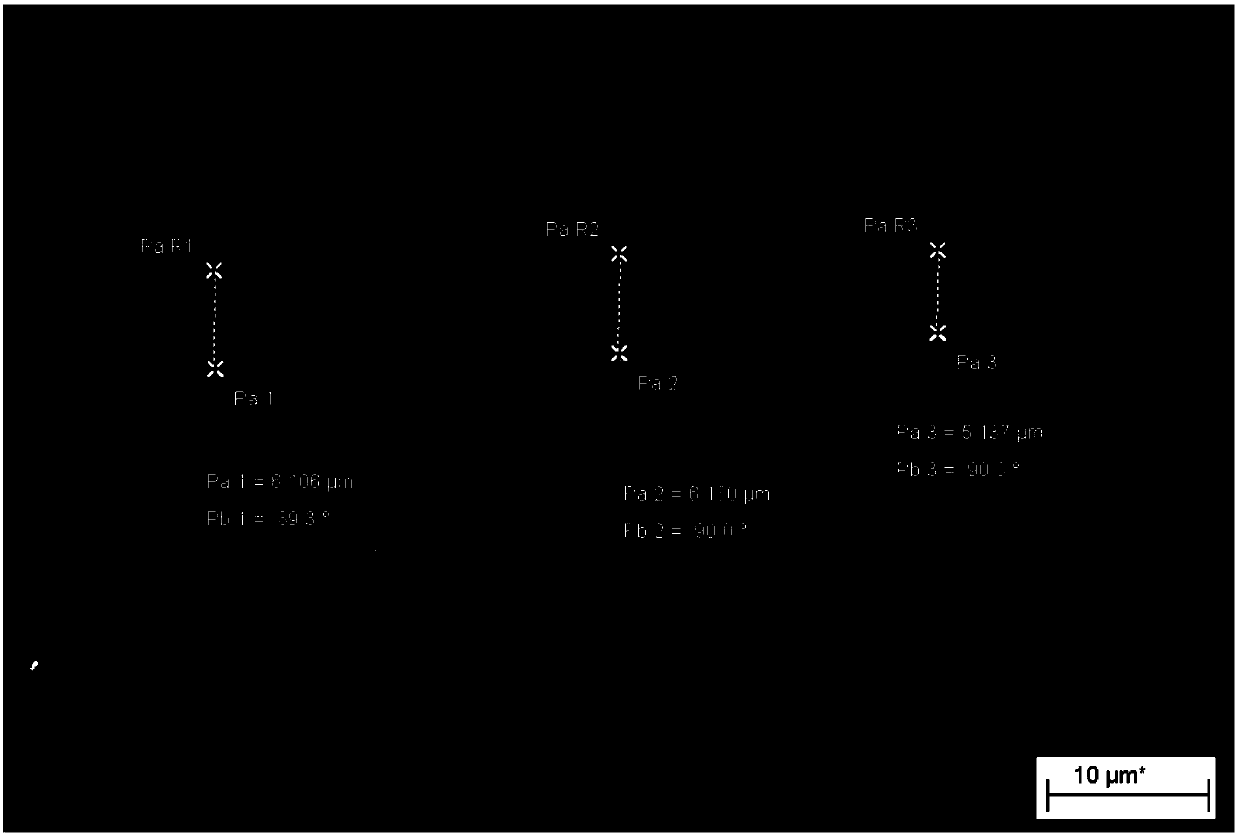

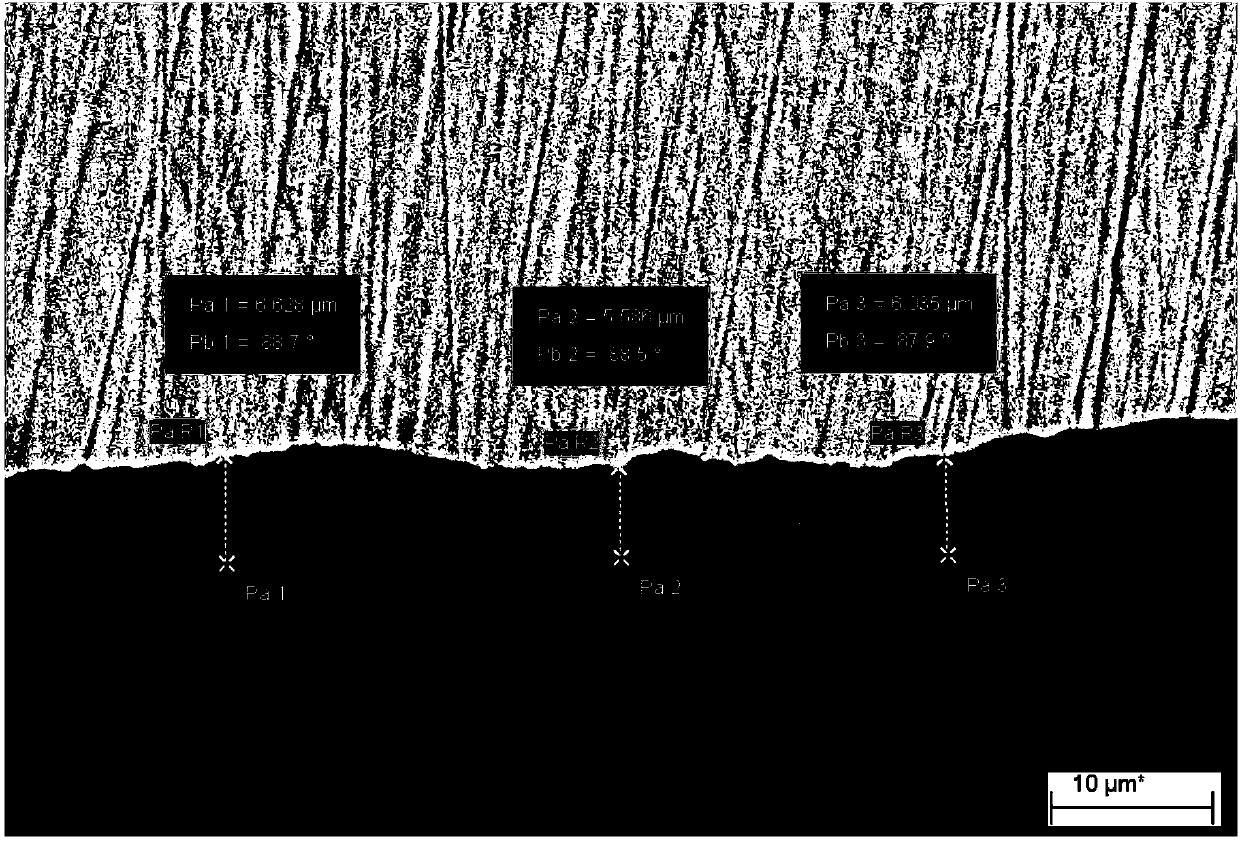

Image

Examples

Embodiment Construction

[0028] The embodiment of the present invention provides a low-carbon and low-silicon hot-rolled coil for mobile conveying pipes and its manufacturing method, which solves the problem that the conventional pipeline steel in the prior art cannot meet the comprehensive mechanical properties and surface requirements of the movable conveying pipeline. The technical problems of quality and plate shape requirements; achieved comprehensive mechanical properties, surface quality and good technical effects of plate shape, providing good raw materials for thin-gauge, small-diameter mobile pipelines, and good surface, which can meet the needs of galvanizing.

[0029] In order to solve the above-mentioned technical problems, the present invention provides a low-carbon and low-silicon hot-rolled coil plate for mobile conveying pipes, which includes the following components in terms of mass percentages: C: 0.02-0.08wt%, Si: 0.01-0.05wt%, Mn: 1.20~1.60wt%, P: ≤0.015wt%, S≤0.002wt%, V: 0~0.05wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com