Method for preparing aluminium nitride powder through high-temperature fusion process

A high-temperature melting, aluminum nitride technology, used in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of difficult control of the reaction process, incomplete nitridation, low cost, etc., to achieve narrow particle size distribution, sphericity High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

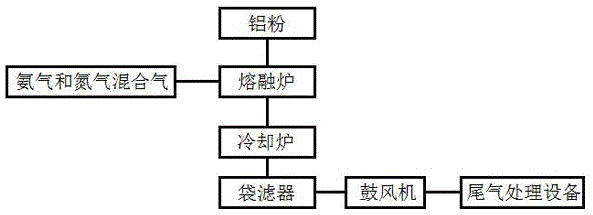

Method used

Image

Examples

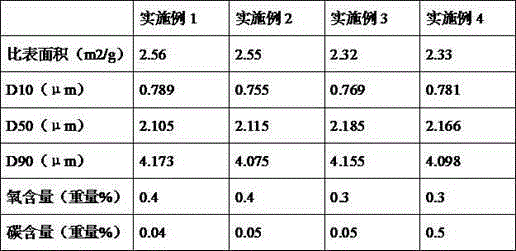

Embodiment 1

[0027] A mixture of ammonia and nitrogen is fed into the melting furnace, the purity of ammonia is 99.9%, the purity of nitrogen is 99.9%, the mixing molar ratio of ammonia and nitrogen is 2:1, and the supply rate is 30L / min for cleaning the air in the furnace;

[0028] The melting furnace is heated up, from room temperature to 1650°C in 5 hours, and kept at 1650°C;

[0029] After heat preservation at 1650°C, the air intake of ammonia and nitrogen mixture is 300L / min. The aluminum powder is ultra-fine atomized aluminum powder, the average particle size of the aluminum powder is 2μm, and the supply rate of the aluminum powder is 400g / min. The cooling water supply rate is 20L / min. During the reaction process, the temperature at the lower end of the cooling tower fluctuates between 340 and 370 °C.

[0030] Finally, the aluminum nitride powder collected by the bag filter has an average particle size of 3 μm, a narrow particle size distribution, high sphericity, and no agglomera...

Embodiment 2

[0032] A mixture of ammonia and nitrogen is fed into the melting furnace, the purity of ammonia is 99.9%, the purity of nitrogen is 99.9%, the mixing molar ratio of ammonia and nitrogen is 2:1, and the supply rate is 30L / min for cleaning the air in the furnace;

[0033] The melting furnace is heated up, from room temperature to 1750°C in 5 hours, and kept at 1750°C;

[0034] After heat preservation at 1750°C, the air intake of ammonia and nitrogen mixture is 300L / min. The aluminum powder is ultra-fine atomized aluminum powder, the average particle size of the aluminum powder is 2μm, and the supply rate of the aluminum powder is 400g / min. The cooling water supply rate is 20L / min. During the reaction process, the temperature at the lower end of the cooling tower fluctuates between 340 and 370 °C.

[0035] Finally, the aluminum nitride powder collected by the bag filter has an average particle size of 3 μm, a narrow particle size distribution, high sphericity, and no agglomera...

Embodiment 3

[0037] Into the melting furnace into the mixed gas of ammonia and nitrogen, the purity of ammonia gas is 99.9%, the purity of nitrogen gas is 99.9%, the mixing molar ratio of ammonia gas and nitrogen gas is 3:1, the supply rate is 30L / min, for exhaust the air in the furnace;

[0038] The melting furnace is heated up, from room temperature to 1650°C in 5 hours, and kept at 1650°C;

[0039] After heat preservation at 1650°C, the air intake of ammonia and nitrogen mixture is 300L / min. The aluminum powder is ultra-fine atomized aluminum powder, the average particle size of the aluminum powder is 2μm, and the supply rate of the aluminum powder is 400g / min. The cooling water supply rate is 20L / min. During the reaction process, the temperature at the lower end of the cooling tower fluctuates between 340 and 370 °C.

[0040] Finally, the aluminum nitride powder collected by the bag filter has an average particle size of 3 μm, a narrow particle size distribution, high sphericity, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com