Multilayer gear

A gear and gear body technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of difficult processing, long processing time, and high processing costs, and reduce the processing difficulty. The effect of improving mechanical properties and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

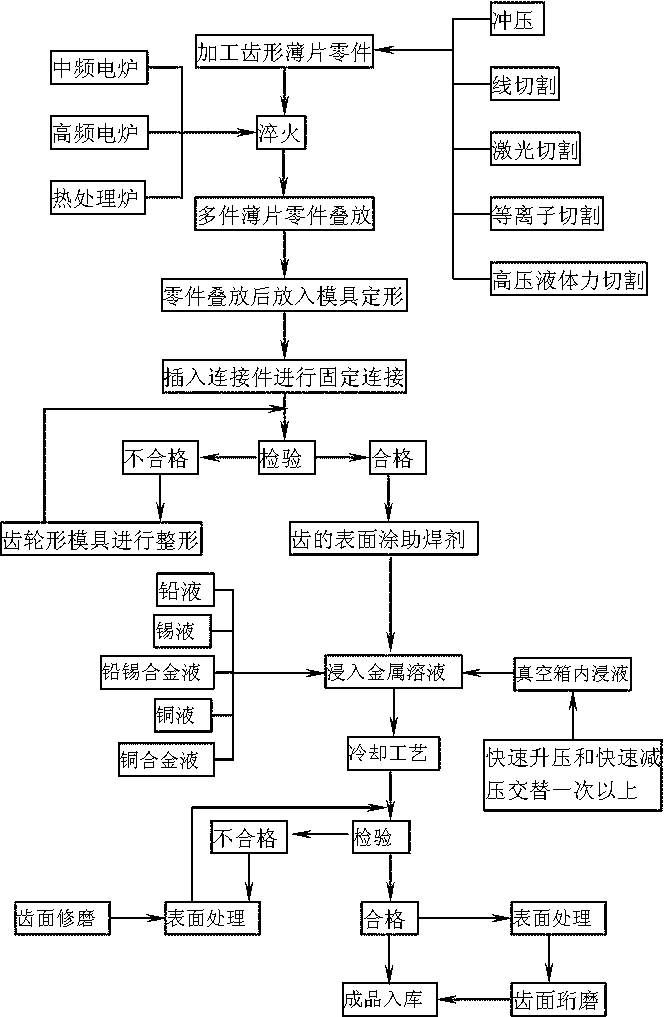

Method used

Image

Examples

example 1

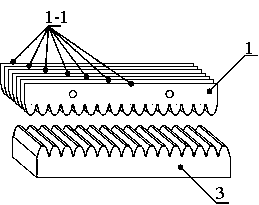

[0074] Example 1: if Figure 1 to Figure 38 As shown, a disclosed multi-layer gear, the gear includes a gear body 5, the gear body 5 is formed by stacking a plurality of quenched toothed sheet parts 1, and at least one of the thin sheet parts 1 is Connecting hole 2, the connecting hole 2 after stacking of multiple sheet parts 1 overlaps to form a through hole, and the connecting holes 2 are fixedly connected with a connecting piece to form a gear body 5, and then the gear body 5 is immersed in the metal solution, and the gear body 5 is formed from the metal solution After being taken out from the medium and cooled, the metal solution is solidified into metal and filled between the thin parts 1 of the gear body 5 and the surface of the gear body 5, and the following processing steps are adopted:

[0075] Step 1): the sheet metal is machined into a toothed sheet part 1; the sheet part 1 has at least one connecting hole 2;

[0076] Step 2): quenching the formed sheet part 1;

...

example 2

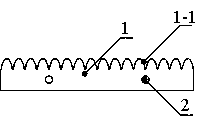

[0085] Example 2: if Figure 1 to Figure 4 As shown, the rack is processed by the method of Example 1, and the following processing steps are adopted:

[0086] Step 1): The 45# steel plate with a thickness of 2mm is processed into a sheet rack-shaped part 1-1 by one of the methods of stamping, wire cutting, laser cutting, plasma cutting, and high-pressure liquid force cutting, and a sheet rack-shaped part 1-1 There are two connecting holes 2;

[0087] Step 2): Carry out quenching treatment in the high-frequency coil of electronic high-frequency furnace to the sheet rack-shaped part 1-1 after forming, quenching adopts any one of processes such as high-frequency quenching, intermediate frequency quenching or heat treatment furnace heating and quenching;

[0088] Step 3): Then 15 thin slice rack-shaped parts 1-1 enter the rack-shaped mold for superposition and splicing to form a rack shape, and the connecting holes 2 after the superimposition of 15 thin slice parts 1 overlap to ...

example 3

[0096] Example 3: if Figure 1 to Figure 2 as well as Figure 5 to Figure 7 As shown, the method of Example 1 or 2 is used to process long racks. When producing long racks, the specific arrangement method of thin slice rack-shaped parts 1-1 is: first, on the rack-shaped mold, more than one thin slice tooth The bar-shaped parts 1-1 are connected to form a long rack-shaped sheet part, and then the multi-layer connection to form a long rack-shaped sheet part is superimposed. The multi-layer spliced long rack-shaped thin sheet parts form a long rack shape, and the connecting holes of the stacked long rack-shaped thin sheet parts overlap to form through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com