Eaglewood extract with allergy-relieving and anti-allergy effects, and preparation method and application thereof

A kind of agarwood extract and soothing technology, which is applied in the field of agarwood extract with soothing and anti-allergic effects and its preparation and application, to achieve scientific compatibility, repair damaged skin, and inhibit hyaluronidase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

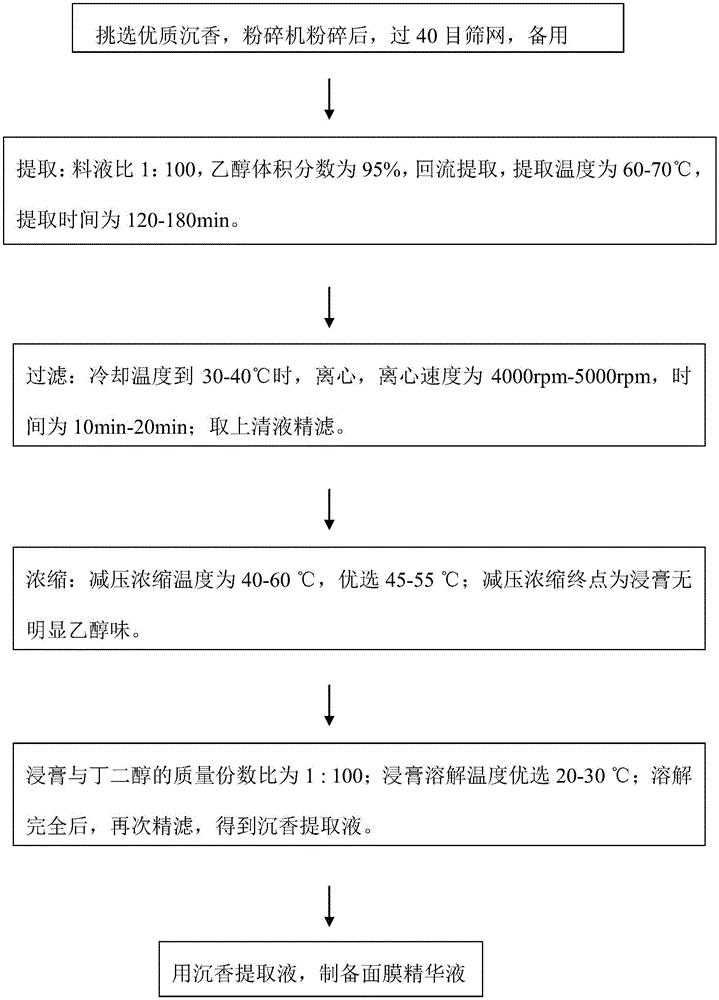

[0061] The preparation of embodiment 1 agarwood extract

[0062] Feeding according to the ratio of material to liquid is 1:20, that is, add 50g of agarwood powder and 1000mL of ethanol solution with a volume fraction of 95% in a round bottom flask, the particle size of the agarwood powder is 40 mesh, and the bottle mouth is connected with a stirring device and a condensation reflux device ; Heating and reflux extraction at 65°C for 180min; stop heating, cool to 35°C, centrifuge at 5000rpm for 10min, take the supernatant and filter it with diatomaceous earth; The liquid has no obvious ethanol smell, and the extract of agarwood extract is obtained; add the extract of agarwood extract and 1,3-butanediol according to the ratio of material to liquid 1:100, stir and dissolve at 25°C for 30min, and filter with a 0.8μm straight plate; measure the pH value and solid content , total sugar, the measurement results are: the pH value is 7.0, the solid content is 60%, and the total sugar is...

Embodiment 2

[0063] The preparation of embodiment 2 agarwood extract

[0064] The production process flow chart of the agarwood extract provided by the invention is as figure 1 As shown, the specific process is as follows:

[0065] Feeding according to the ratio of material to liquid is 1:10, that is, add 50g of agarwood powder and 500mL of ethanol solution with a volume fraction of 60% in a round bottom flask, the particle size of the agarwood powder is 20 mesh, and the bottle mouth is connected with a stirring device and a condensation reflux device ; Heated and refluxed at 50°C for 180min; stopped heating, cooled to 30°C, centrifuged at 4000rpm for 20min, took the supernatant and filtered it with diatomaceous earth; The liquid has no obvious ethanol smell, and the extract of agarwood extract is obtained; the extract of agarwood extract and propylene glycol are added according to the ratio of material to liquid 1:50, stirred and dissolved at 20°C for 30 minutes, and filtered with a 0.2 ...

Embodiment 3

[0066] The preparation of embodiment 3 agarwood extract

[0067] Feeding according to the ratio of material to liquid is 1:30, that is, add 50g of agarwood powder and 1500mL of ethanol solution with a volume fraction of 80% in a round bottom flask. ; Heating and reflux extraction at 70°C for 150min; stop heating, cool to 40°C, centrifuge at 4500rpm for 15min, take the supernatant for fine filtration on a filter plate, and filter with diatomaceous earth; take the filtrate, concentrate under reduced pressure at 45-55°C and 0.1MPa to The liquid has no obvious ethanol smell, and the extract of agarwood extract is obtained; the extract of agarwood extract and glycerin are added according to the ratio of solid to liquid at 1:80, stirred and dissolved at 30°C for 30min, and filtered with a 10μm straight plate; the pH value, solid content, and total sugar are measured, and the results are: : The pH value is 8.0, the solid content is 50%, and the total sugar is 15 mg / mL; heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com