Preparation method of grapheme-based electrode materials through defect initiation

A graphene-based, electrode material technology, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of complex process, difficult to accurately grasp the degree of improvement and the mechanism of surface modification, and achieve a simple method and good cycle stability. performance, saving production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

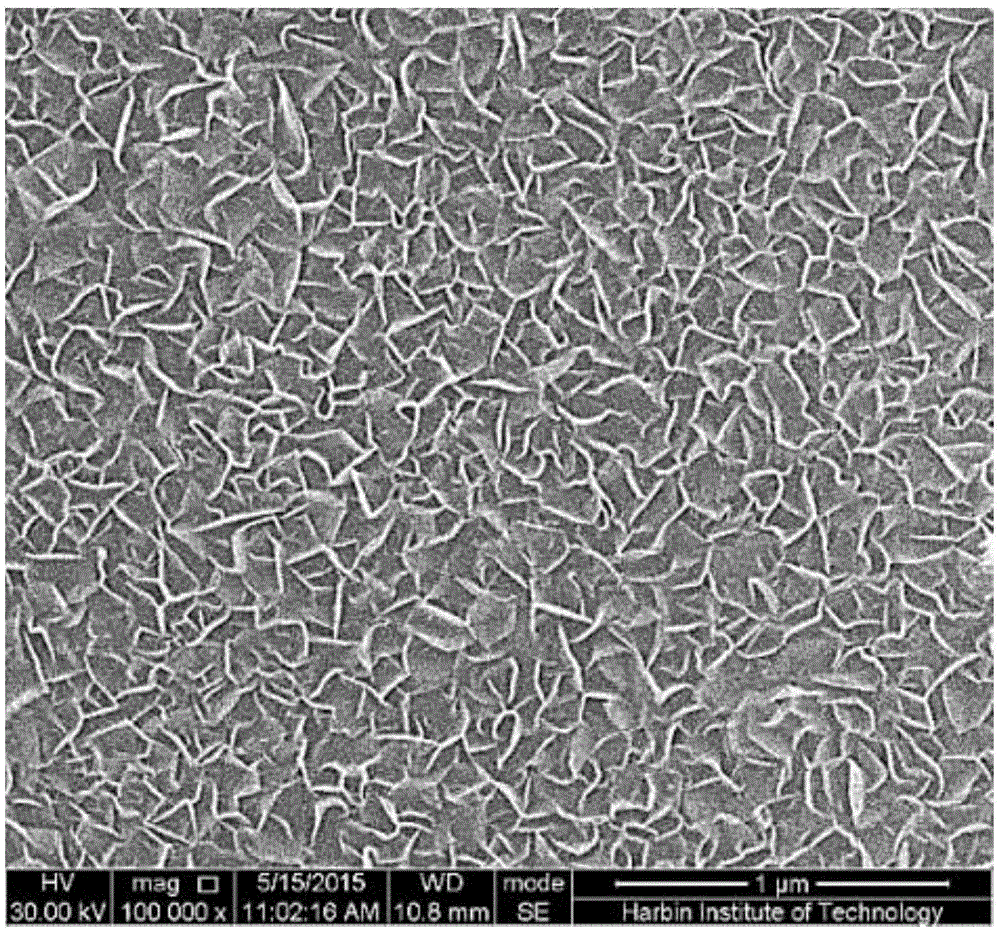

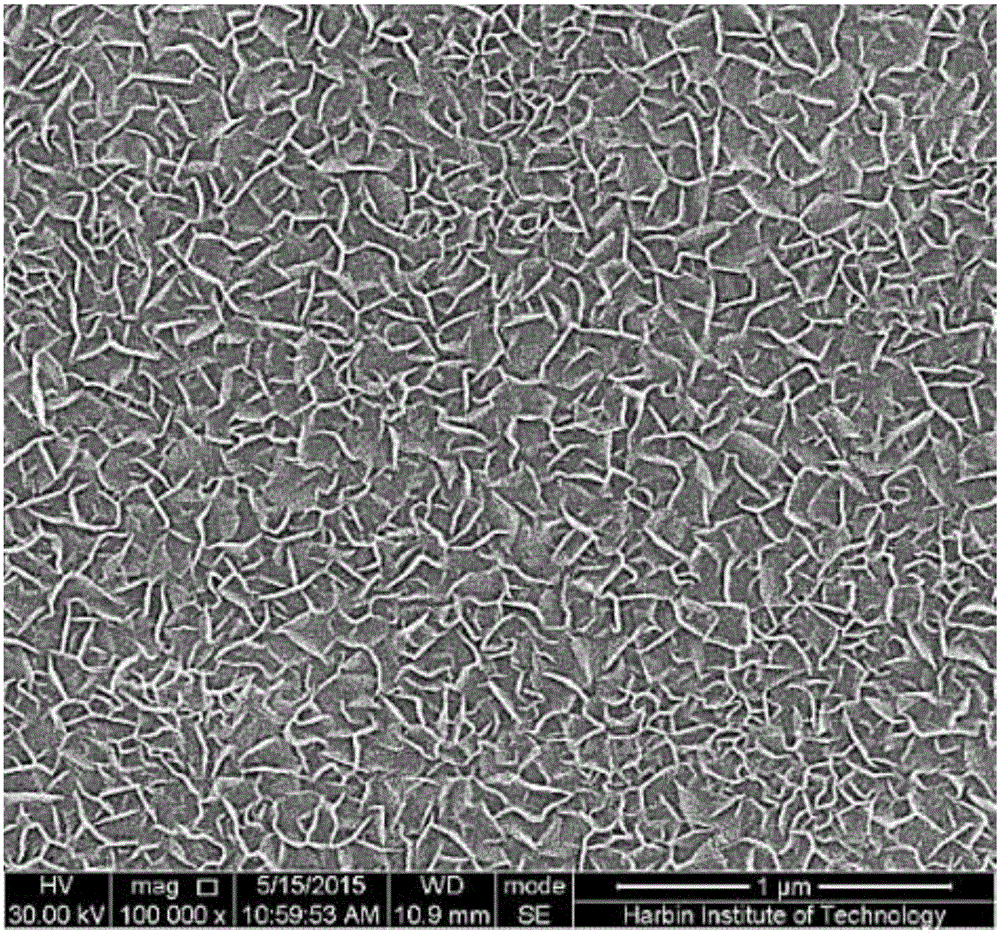

[0018] Embodiment 1: The preparation method of a defect-induced graphene-based electrode material described in this embodiment is specifically carried out according to the following steps:

[0019] 1. Place the collector material in a plasma-enhanced chemical vapor deposition vacuum device at a temperature of 300°C to 800°C, a pressure of 200Pa to 900Pa, a radio frequency power of 75W to 225W, and an argon gas flow rate of 40sccm to 120sccm and CH 4 Under the condition that the gas flow rate of the gas is 5sccm-50sccm, the deposition time is 5min-60min, and the collector material for depositing graphene is obtained;

[0020] 2. After the deposition is over, close the CH 4 Gas, adjust the temperature until the etching temperature is 400 ℃ ~ 800 ℃, adjust the gas flow rate of argon gas to 5 sccm ~ 100 sccm, adjust the etching pressure to 50 Pa ~ 300 Pa, after turning on the plasma power, adjust the radio frequency power to 100W ~ 200W, at the same time Rotate the sample stage ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the collector material described in step 1 is metal nickel, copper, aluminum, iron, gold, platinum, nickel foam, carbon fiber cloth or graphite paper. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 2, the temperature is adjusted to an etching temperature of 400° C. to 700° C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com