Pigment yellow 38 emulsion and preparation method thereof

A technology for pigment yellow and emulsion, applied in the direction of pigment slurry, etc., can solve problems such as poor solubility, achieve good stability and solve the effect of solubility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Pulverize Pigment Yellow 38 with a pulverizer, the pulverization time is 15 minutes, and pulverize until Pigment Yellow 38 has a mesh number of 200 mesh or more;

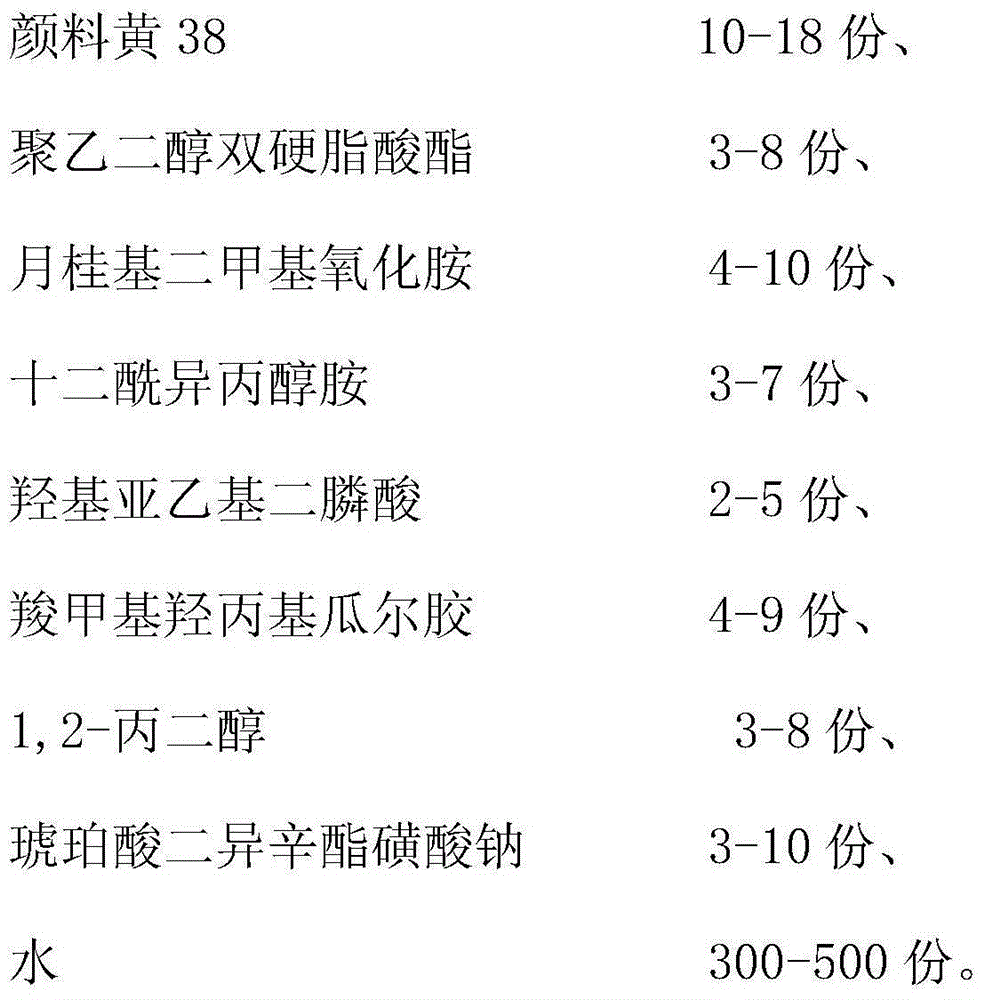

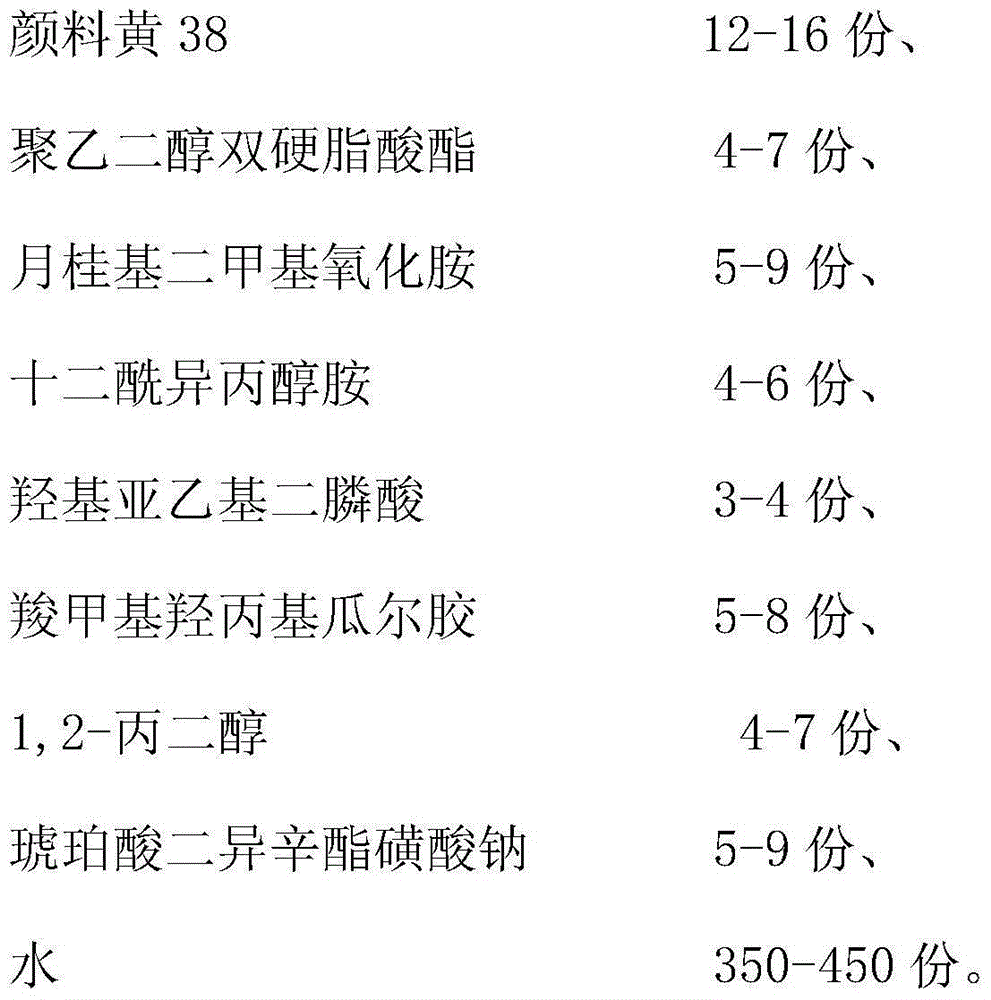

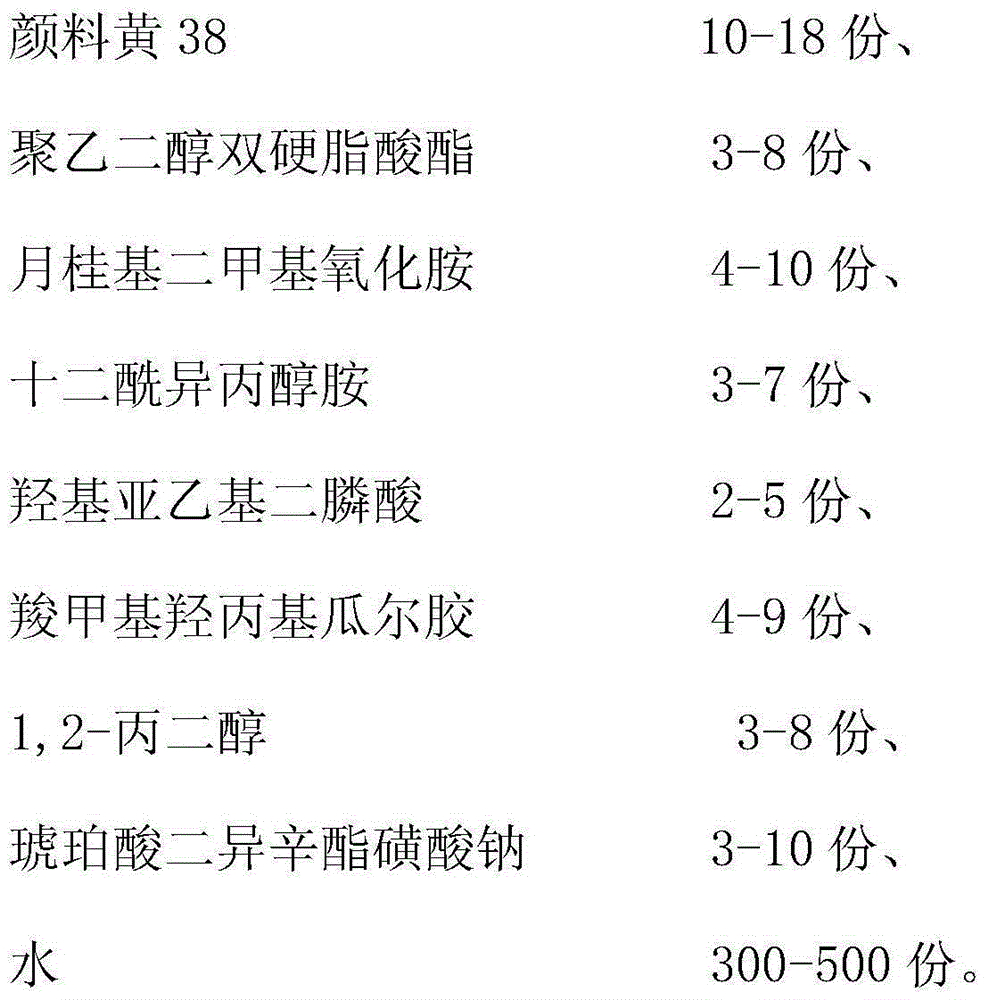

[0019] (2) By weight, 18 parts of Pigment Yellow 38 after pulverization, 3 parts of polyethylene glycol distearate, 4 parts of lauryl dimethyl amine oxide, 7 parts of lauryl isopropanolamine, hydroxyl 5 parts of ethylene diphosphonic acid were mixed and stirred in a stirred tank, the rotating speed of the stirred tank was 200rpm, and the stirring time was 20min;

[0020] (3) Take another 9 parts of carboxymethylhydroxypropyl guar gum, 3 parts of 1,2-propanediol, 10 parts of dioctyl sodium sulfosuccinate, and 500 parts of water by weight, put them into the stirring tank and then Stir for 0.5 h at a temperature of 60° C. to prepare Pigment Yellow 38 emulsion.

[0021] The Pigment Yellow 38 emulsion in Example 1 was centrifuged at 3000 rpm for 30 minutes without stratification, and after being dissolved in ...

Embodiment 2

[0023] (1) Pulverize Pigment Yellow 38 with a pulverizer, the pulverization time is 5 minutes, and pulverize until the number of pigment yellow 38 is more than 200 mesh;

[0024] (2) 10 parts of pigment yellow 38 after pulverization, 8 parts of polyethylene glycol distearate, 10 parts of lauryl dimethyl amine oxide, 3 parts of lauryl isopropanolamine, hydroxyl 2 parts of ethylene diphosphonic acid are mixed and stirred in a stirred tank, the rotating speed of the stirred tank is 50rpm, and the stirring time is 40min;

[0025] (3) Take 4 parts of carboxymethyl hydroxypropyl guar gum, 8 parts of 1,2-propanediol, 3 parts of dioctyl sodium sulfosuccinate, and 300 parts of water in addition by weight, put them into the stirring tank and then Stir for 2 hours at a temperature of 45° C. to prepare Pigment Yellow 38 emulsion.

[0026] The Pigment Yellow 38 emulsion in Example 2 was centrifuged at 3500 rpm for 20 minutes without stratification, and after being dissolved in water at 20...

Embodiment 3

[0028] (1) Pulverize Pigment Yellow 38 with a pulverizer, the pulverization time is 15 minutes, and pulverize until Pigment Yellow 38 has a mesh number of 200 mesh or more;

[0029] (2) 16 parts of Pigment Yellow 38 after pulverization, 7 parts of polyethylene glycol distearate, 5 parts of lauryl dimethyl amine oxide, 6 parts of lauryl isopropanolamine, and hydroxyl 4 parts of ethylene diphosphonic acid are mixed and stirred in a stirred tank, the rotating speed of the stirred tank is 200rpm, and the stirring time is 20min;

[0030] (3) Take 5 parts of carboxymethyl hydroxypropyl guar gum, 7 parts of 1,2-propanediol, 9 parts of diisooctyl sodium sulfosuccinate, and 350 parts of water in addition by weight, put them into the stirring tank and then Stir for 0.5 h at a temperature of 60° C. to prepare Pigment Yellow 38 emulsion.

[0031] The Pigment Yellow 38 emulsion in Example 3 was centrifuged at 5000 rpm for 15 minutes without stratification, and after being dissolved in wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com