Comprehensive treatment apparatus and method for non-dosage form circulating cooling water

A technology for circulating cooling water and water treatment devices, which is used in water/sewage multi-stage treatment, water/sludge/sewage treatment, cleaning heat transfer devices, etc. Environmental pollution, high cleaning costs, etc., to prevent leakage of heat exchangers and pipelines, save high cleaning costs, and save production fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

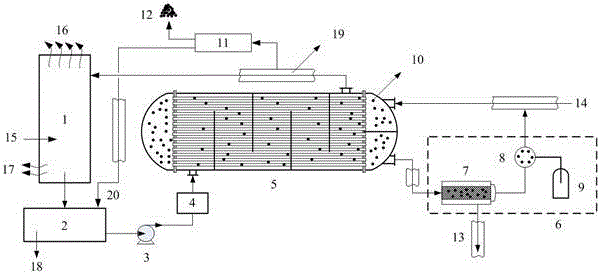

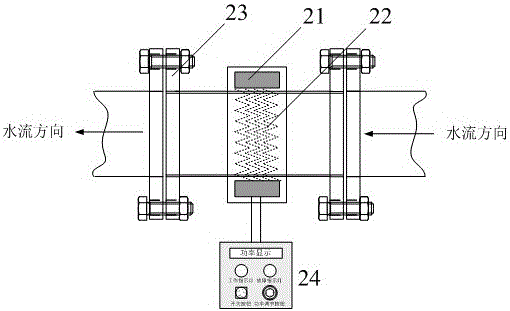

[0033] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] Please refer to figure 1 , figure 2 , the general operation process of the circulating cooling water system is as follows: the cooling water circulating pump (3) pumps the water in the cooling water pool (2) and sends it to the shell-and-tube heat exchanger (5), and the process from the heat exchange process pipeline (14) The medium returns to the cooling water tower (1) after heat exchange, and the cooling water completes a cycle process. During this process, the circulating cooling water will lose part of the cooling water due to evaporation (16) and wind blowing (17), and due to evaporation (16), the cooling water will gradually condense and cause the ion concentration to rise. In order to maintain the ion concentration of the circulating cooling water Balance, so blowdown (18) and make-up water with low ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com