Method and equipment for production of titanium dioxide by sulphate process

A sulfuric acid method and titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increasing the concentration cost and increasing the burden of titanium liquid concentration, so as to avoid the increase of concentration cost, improve the blockage of pipeline valves and Delivery pump, avoiding the effect of burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0059] It is used to illustrate the device and method for producing titanium dioxide by sulfuric acid method provided by the present invention.

[0060] The equipment adopted in embodiment 1-4 is specified as follows:

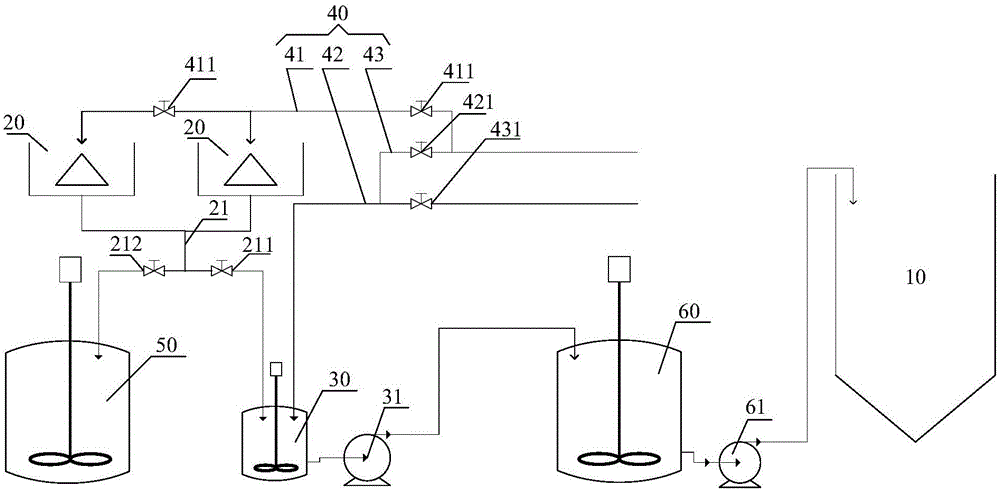

[0061] Such as figure 1 As shown, the equipment for sulfuric acid production of titanium dioxide provided by the present invention includes acidolysis / leaching device 10, crystallization device (not shown in the figure), crystal separation device (not shown in the figure), dilution tank 30, process Circulating water pipeline 40, crystallized titanium liquid tank 50, small degree water tank 60, and calcining device (not shown in the figure). in,

[0062]The crystal separation device is arranged downstream of the acidolysis / leaching device 10 and the crystallization device, and includes multiple groups of centrifuges 20, and the centrifugal liquid outlet ends of the multiple groups of centrifuges 20 pass through the centrifugal mother liquor delivery pipeline 2...

Embodiment 1

[0069] Referring to the method for producing titanium dioxide by the sulfuric acid method in Comparative Example 2, the difference is that: the centrifuged mother liquor and the sewage circulating water (the filtered calcination tail gas is sprayed with waste water, the temperature is 40° C.) in the dilution tank 30 in a weight ratio of 1:2.5 Mix to form a centrifugal mother liquor dilution, and use the centrifugal mother liquor dilution as a part of the leaching water, and add it to the acidolysis maturation system in the acidolysis / leaching device 10 through the small water tank 60 (that is, add it to the leaching step), and The consumption of described centrifugal mother liquor diluent is 15wt%-20wt% of described leaching water consumption, and the consumption of centrifugal mother liquor diluent is controlled so that TiO in titanium sulfate solution after leaching step 2 The concentration is 120-125g / L.

Embodiment 2

[0071] Referring to the method for producing titanium dioxide by the sulfuric acid method in Comparative Example 2, the difference is that: the centrifuged mother liquor and the net circulating water (circulating water from the cooling equipment) are mixed in a weight ratio of 1:2 to form a centrifugal mother liquor dilution, and the centrifugal mother liquor dilution is As part of the leaching water, it is added to the acidolysis maturation system in the acidolysis / leaching device 10 through the small water tank 60 (that is, added to the leaching step), and the amount of the centrifuged mother liquor dilution is the leaching The 25wt%-30wt% of water consumption, the consumption of centrifugal mother liquor diluent is controlled to make TiO in titanium sulfate solution after leaching step 2 The concentration is 130-140g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com