Stone material line polisher and polishing method thereof

A technology of polishing machine and stone, which is applied in surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc. It can solve problems such as poor working environment, affecting polishing effect, and difficulty in taking out stones. achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

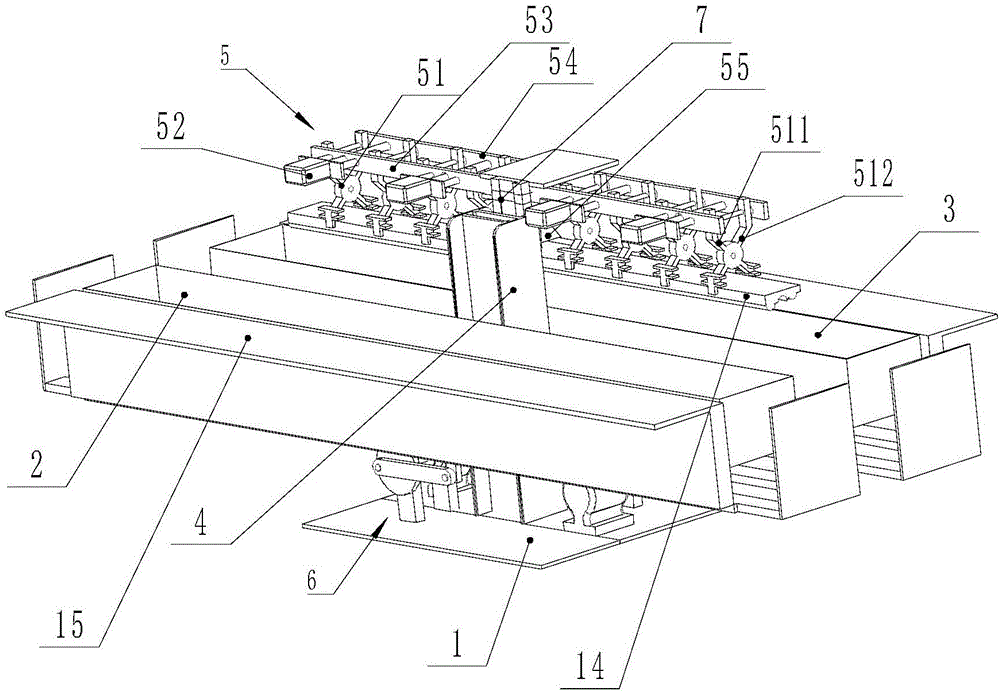

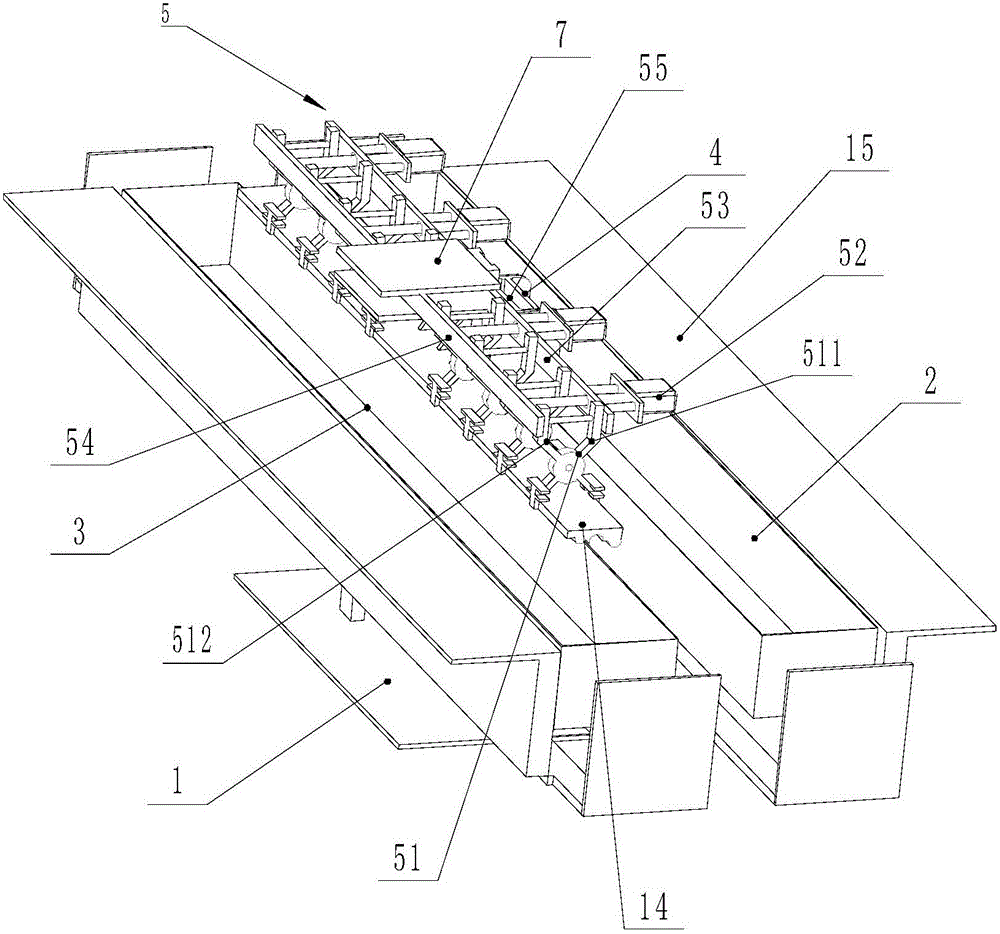

[0034] Such as figure 1As shown, a stone line polishing machine includes a frame 1, a trough is installed on the frame 1, and abrasive materials for contacting and polishing the surface of the stone to be polished are filled in the trough: the stone can be marble or For other stone materials that need to be polished and polished, the trough can be made of wear-resistant materials. The frame 1 is also vertically slidably equipped with a vertical slide seat 7, and the vertical slide seat 7 and the vertical drive device 9 Connected, the vertical drive device 9 can be driven by a cylinder or a linear motor, and the vertical slide 7 is equipped with a clamping assembly 5 for laterally clamping or loosening the stone, and the clamping assembly 5 clamps the stone in the trough Among them, the trough is driven to reciprocate and slide longitudinally by the horizontal reciprocating drive device 6 or the clamping assembly 5 is driven to reciprocate and slide longitudinally by the horizo...

Embodiment 2

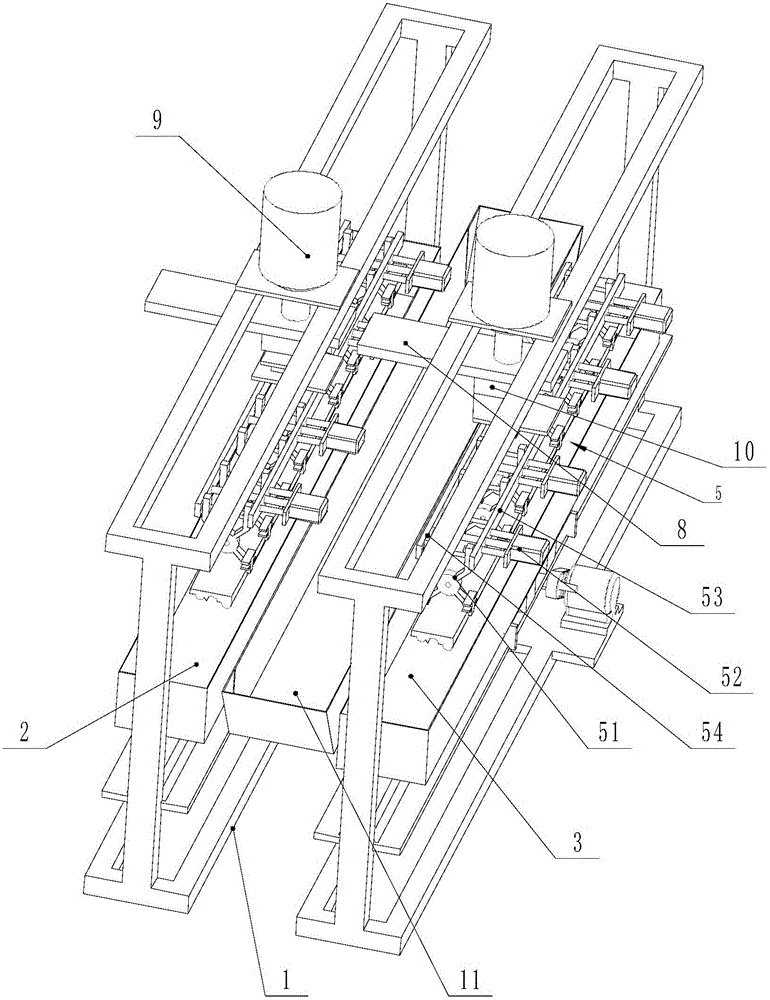

[0045] Such as image 3 , Figure 4 As shown, this embodiment is also improved on the basis of the most basic solution described in embodiment 1.

[0046] In this solution, at least two feed troughs arranged side by side are installed on the frame 1, and the preferred feed chute is horizontally reciprocating at this time, and the number of vertical sliding seats 7 on the described frame 1 matches the number of feed troughs , each vertical sliding seat 7 is equipped with a horizontal and horizontal telescopic block 8, each telescopic block 8 is driven by a telescopic power device, and the telescopic power device can be a cylinder or other linear power device, each telescopic block 8 The clamping assembly 5 is installed through the connecting seat 10, and each telescopic power device drives the clamping assembly 5 on the corresponding telescopic block 8 to reciprocate and slide between its corresponding trough and the adjacent trough on the same side . That is to say, the tel...

Embodiment 3

[0051] This embodiment has been changed on the basis of embodiment 2,

[0052] Such as Figure 5 and Figure 6 As shown, the telescopic block 8 is also used to realize the material fetching from the adjacent trough on the same side, but the clamping assembly 5 adopts a manual clamping mode, and a movable clamp is used between the clamping assembly 5 and the telescopic block 8 Clamping or disengagement is achieved by disassembling the connection, and each clamping assembly 5 is connected to the telescopic block 8 through a quick connection mechanism, which realizes quick connection or separation between the clamping assembly 5 and the telescopic block 8 . The quick connection mechanism includes a clamped seat 13 arranged on the clamping assembly 5 , and the telescopic block 8 is provided with a clamping mechanism 12 for clamping or releasing the clamped seat 13 . The clamping mechanism 12 includes two clamping blocks 121 that cooperate with each other to clamp the clamped se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com