A Method of Improving the Welding Efficiency of Double-sided Welding

A welding efficiency, double-sided welding technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problem of welding seam embrittlement, achieve good alloying uniformity, reduce welding workload, and reduce welding seam effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

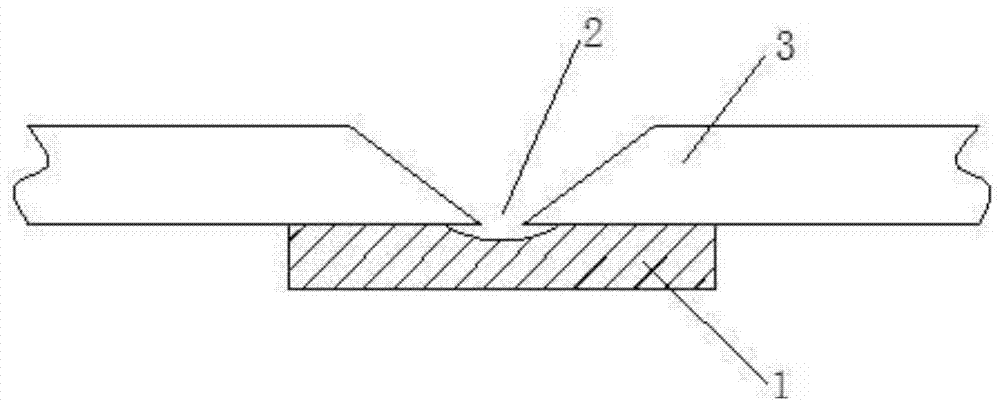

Image

Examples

Embodiment 1

[0047] Embodiment 1: high-strength weather-resistant steel plate (thickness = 3.8mm) flux-cored welding wire ceramic liner single-sided welding double-sided forming flat butt welding. Welding conditions:

[0048] (1) Welding requirements for flat butt joints: the inclination angle of the weld seam is 0°, the deviation is ±5°, the weld seam rotation angle is 90°, the deviation is ±10°;

[0049] (2) The welding equipment is: WSE-250 argon arc welding machine;

[0050] (3) The welding wire is: flux-cored wire, Ф1.0mm; the formula of the alloy powder constituting the flux-cored wire is as follows in parts by mass: electrolytic manganese 8, 45# ferrosilicon 6, ferro-titanium 4, metal chromium 35, high-carbon ferrochrome 30, graphite 5, vanadium iron 6, molybdenum iron 18, tungsten powder 4, nickel powder 8, aluminum nitride 2, titanium nitride 6, potassium feldspar 2, sodium fluorosilicate 4, marble 25, fluorite 15, titanium white powder 1-3, quartz 5, mica 5;,

[0051] (4) The ...

Embodiment 2

[0060] Embodiment 2: high-strength weather-resistant steel (thickness = 3.8mm) flux-cored welding wire ceramic backing single-sided welding double-sided forming flat butt welding.

[0061] Welding conditions:

[0062] (1) Welding requirements for flat butt joints: the inclination angle of the weld seam is 0°, the deviation is ±5°, the weld seam rotation angle is 90°, the deviation is ±10°;

[0063] (2) The welding equipment is: WSE-250 argon arc welding machine;

[0064] (3) The welding wire is: flux-cored wire, Ф1.0mm; the formula of the alloy powder constituting the flux-cored wire is as follows in parts by mass: electrolytic manganese 4, 45# ferrosilicon 2, ferro-titanium 1, metal chromium 20, high-carbon ferrochrome 20, vanadium iron 2, molybdenum iron 12, tungsten powder 2, nickel powder 4, aluminum nitride 1, titanium nitride 2, potassium feldspar 1, sodium fluorosilicate 1, marble 20, fluorite 10, titanium dioxide 1, Quartz 2, Mica 2;

[0065] (4) The ceramic liner i...

Embodiment 3

[0074] Embodiment 3: high-strength weather-resistant steel (thickness = 3.8 mm) flux-cored welding wire ceramic backing single-sided welding double-sided forming flat butt welding.

[0075] Welding conditions:

[0076] (1) Welding requirements for flat butt joints: the inclination angle of the weld seam is 0°, the deviation is ±5°, the weld seam rotation angle is 90°, the deviation is ±10°;

[0077] (2) The welding equipment is: WSE-250 argon arc welding machine;

[0078] (3) The welding wire is: flux-cored wire, Ф1.0mm; the alloy powder formula of the flux-cored wire is as follows in parts by mass: electrolytic manganese 6, 45# ferrosilicon 4, ferro-titanium 3, metal chromium 30, high-carbon ferrochrome 25, graphite 3, vanadium iron 4, molybdenum iron 16, tungsten powder 3, nickel powder 6, aluminum nitride 1.5, titanium nitride 4, potassium feldspar 1.5, sodium fluorosilicate 2.5, marble 24, fluorite 12, titanium White powder 2, quartz 4, mica 3;

[0079] (4) The ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com