Mushroom bran protein peptide capable of replacing fish meal and preparation method and application of mushroom bran protein peptide in aquaculture

A technology for replacing fish meal and protein peptides, applied in the field of microorganisms and aquaculture feed, can solve the problems of shortage of protein source and low utilization rate of protein, and achieve the effects of easy popularization, strong practical operability, and increased crude polysaccharide content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 mycofurfur protein peptide

[0054] (1) Bacteria chaff pretreatment

[0055] Crush 2000g of edible fungus chaff and remove visible impurities, then transfer to an oven, dry at 50°C until the water content is less than 5%, crush, pass through a 40-mesh sieve, and set aside.

[0056] (2) Bacteria chaff fermentation

[0057] ① Preparation of culture medium

[0058] PDA slant medium: Weigh 200g of potatoes, peel them, cut them into small pieces, add 1L of deionized water and boil for 30min, add deionized water appropriately during the boiling process; then filter, and dilute the obtained filtrate to 1L with deionized water; Then add glucose 20g, agar 20g, pH natural. Sterilize at 121°C for 30 minutes to make a slope.

[0059] Malt juice agar medium: Weigh 145.1 g of malt juice agar medium, add 1 L of deionized water, stir, heat and boil until completely dissolved, sterilize at 115°C for 15 minutes, and make a slope.

[0060] Ganoderma lu...

Embodiment 2

[0072] The mensuration of embodiment 2 mycofurfur protein peptides

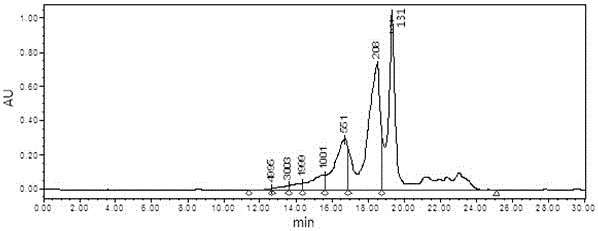

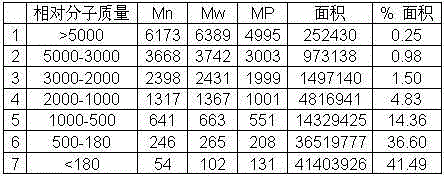

[0073] (1) Determination of molecular weight distribution

[0074] Weigh 20mg of mycofurfurin peptide powder into a 10mL volumetric flask, use the mobile phase (acetonitrile: water: trifluoroacetic acid = 45: 55: 0.1, volume ratio) to adjust the volume to the mark, and ultrasonically oscillate for 10 minutes to fully dissolve the sample. 0.22μm nylon filter membrane, and analyzed by gel chromatography. Analysis conditions: Waters1525, chromatographic column TSKgelG2000SWXL300mm×7.8mm; mobile phase is acetonitrile: water: trifluoroacetic acid = 45:55:0.1 (volume ratio); detection wavelength UV220nm; flow rate 0.5mL / min, column temperature 30°C, sample injection The volume is 10 μL, the column calibration of the gel chromatographic column is not less than 5000 according to the peak calculation of the standard (tyrosine-thyrosine-tyrosine-arginine), and the distribution coefficient (Kd) of the oligopeptide is b...

Embodiment 3

[0084] Example 3: Feeding crucian carp with mycofurin peptide

[0085] The experiment was completed in the laboratory of the Freshwater Fishery Research Center of the Chinese Academy of Fishery Sciences. Fish species are provided by the central fishery. A total of 540 crucian carp with the same health, size and weight were selected, and the initial weight of the individual was (20±0.5) g. The fish species were randomly divided into 6 groups, with 3 replicates in each group, and 30 fish in each replicate. They were stocked in cages with a size of 1.00m×1.00m×1.00m in repetition units.

[0086] The basic feed was formulated with reference to the Chinese aquatic industry standard SC / T074-2004. The control group was fed with basal feed (10% fish meal, no mycofurin peptide); the test group was fed with mycofurin peptide in the basal feed, and the corresponding amount of fish meal was subtracted at the same time, of which: test group 1 (fish meal 8.4%, bacteria furfur protein pep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com