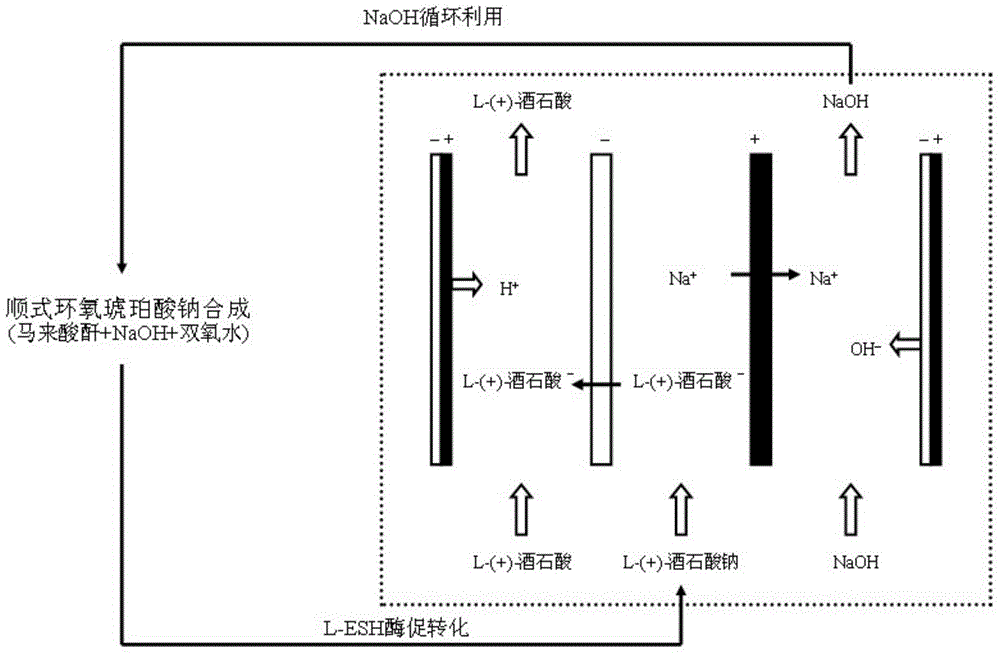

L-(+)-tartaric acid clean production process based on bipolar membrane electroosmosis technology

A technology of tartaric acid and sodium tartrate, which is applied in carboxylate preparation, organic chemistry, fermentation, etc., can solve the problems of low production efficiency, unsatisfactory output, and different content, so as to improve production efficiency, avoid cumbersome production steps, and significantly industrialize Effect of application value and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the following examples 2-4, the model of the bipolar membrane electrodialyzer used is CJ-BMED-A, produced by Hefei Kejia Polymer Material Technology Co., Ltd., with an overall size of 650×650×950mm, and a membrane stack The size is 170mm×110mm, and the ion exchange membrane is acid and alkali resistant. Preparation of Example 1 L-type cis-epoxysuccinate hydrolase and its enzymatic hydrolysis

[0036] The gene fragment of SEQ ID NO: 1 was connected to the pBV220 plasmid vector, and then the recombinant plasmid was introduced into E.coliBL21 (DE3) competent cells to obtain recombinant L-type cis-epoxysuccinate hydrolase engineering bacteria. The cultivation conditions of engineering bacteria are as follows: put 100mL of LB medium in a 500mL Erlenmeyer flask, pick a single colony of engineering bacteria and insert it into the medium, place it at 37°C and shake it at 200rpm. When OD600=0.6-0.8, set the temperature After raising the temperature to 42°C for 5 hours, the i...

Embodiment 2

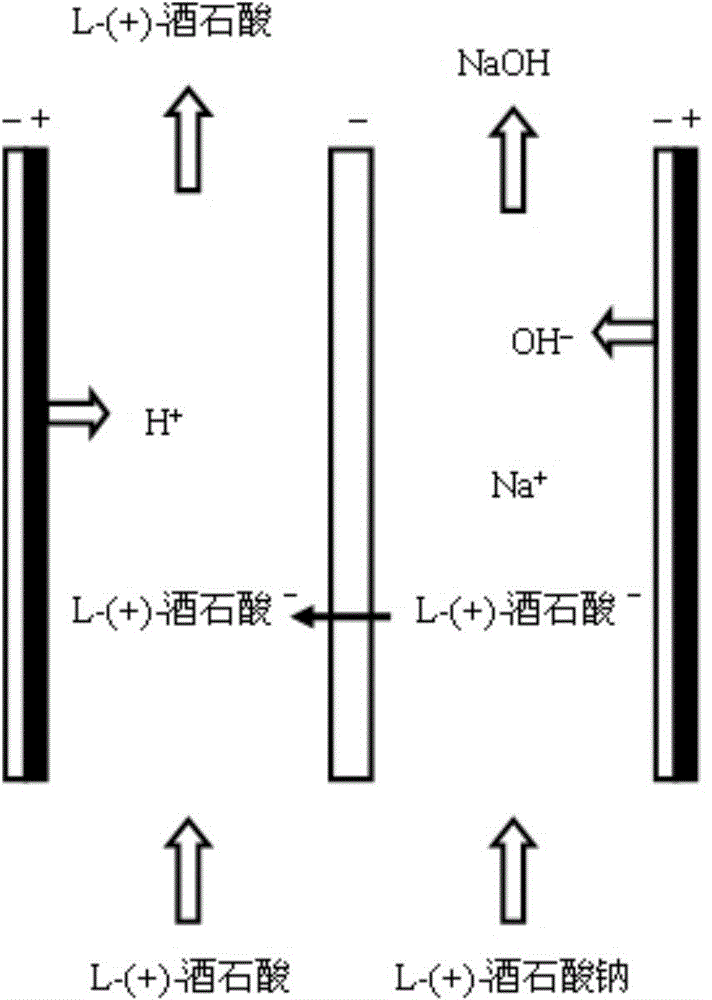

[0038] Example 2 Salt / acid two-chamber electrodialysis device prepares L-(+)-tartaric acid

[0039] 2L is pumped into the salt chamber of salt / acid two-chamber electrodialyzer ( figure 2 ), while pumping 0.5L of 0.2M L-(+)-tartaric acid solution into the acid chamber at a rate of 40L / h to increase its conductivity. The voltage is controlled to maintain the current density at 140mA / cm2, the operating temperature is 50°C, and the cycle reaction is 6h. The conversion rate of L-(+)-tartrate reaches 90%, the energy consumption is 2.13kW h / kg, and the current efficiency is 87 %, the recovery rate of L-(+)-tartaric acid reached 96%.

Embodiment 3

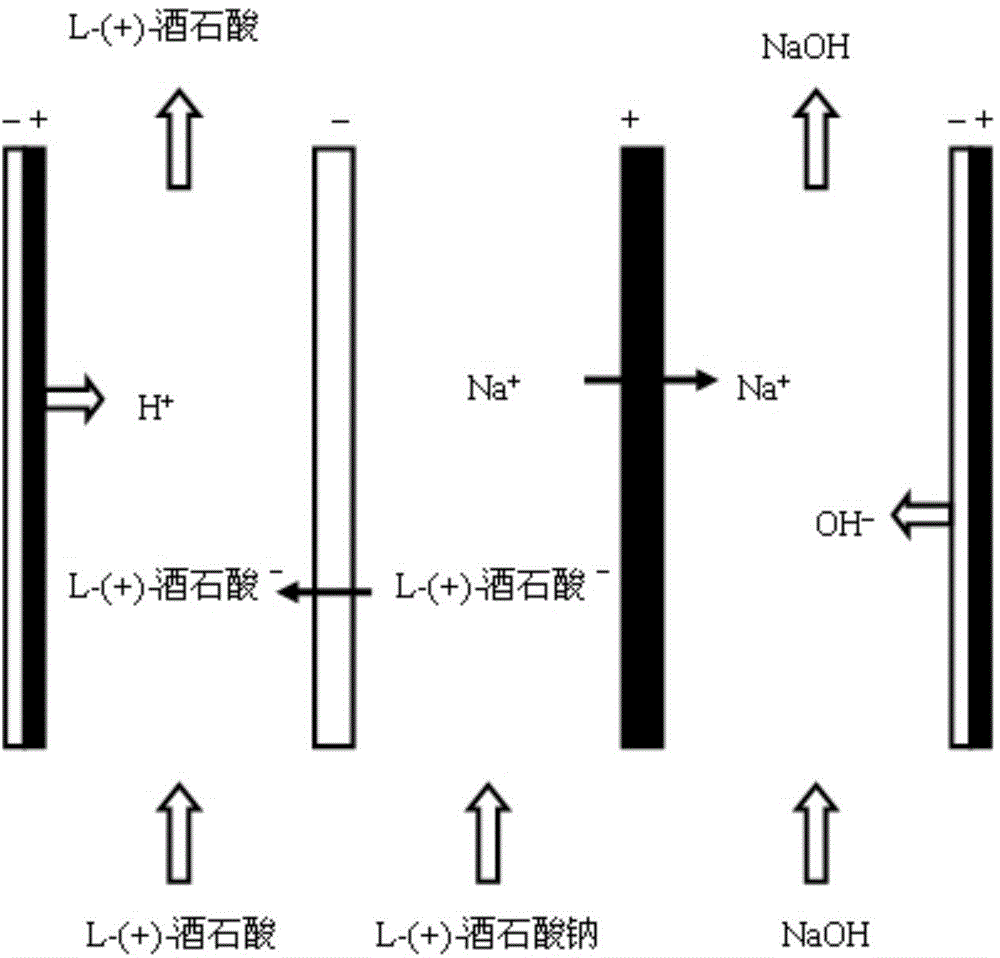

[0040] Example 3 Acid / salt / alkali three-chamber electrodialysis device prepares L-(+)-tartaric acid

[0041] 2L is pumped into the salt chamber of acid / salt / alkali three chamber type electrodialyzer ( image 3 ), while pumping 1L0.2M L-(+)-tartaric acid solution into the acid chamber at a speed of 60L / h, and pumping 1L0.1M NaOH solution into the alkali chamber at a speed of 60L / h to increase its conductivity . Control the voltage to maintain the current density at 80mA / cm 2 , the operating temperature is 40°C, the cycle reaction is 6h, the conversion rate of L-(+)-tartrate reaches 95%, the energy consumption is 2.43kW h / kg, the current efficiency is about 89%, and the L-(+)-tartaric acid The recovery rate reaches 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com