Application of a foam stabilizer in the preparation of polyurethane foam products

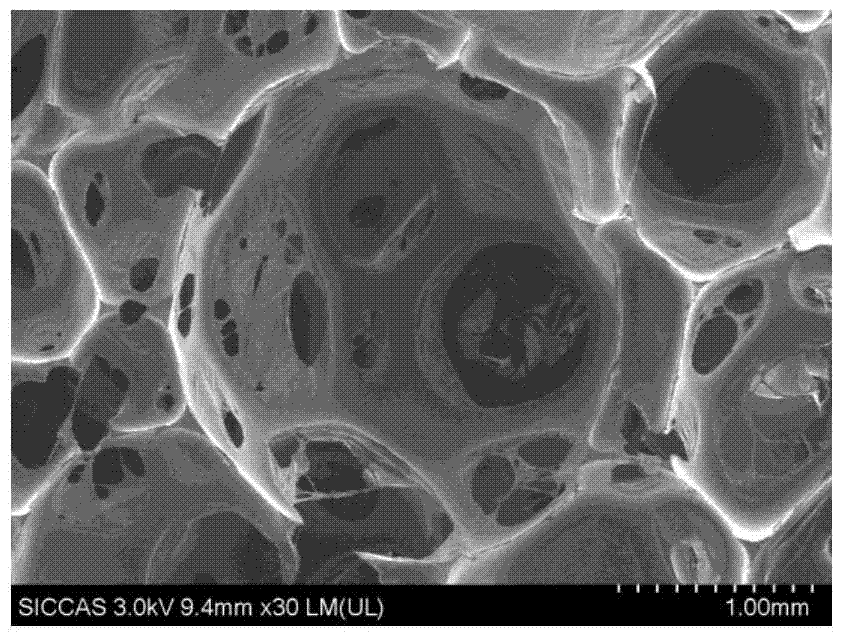

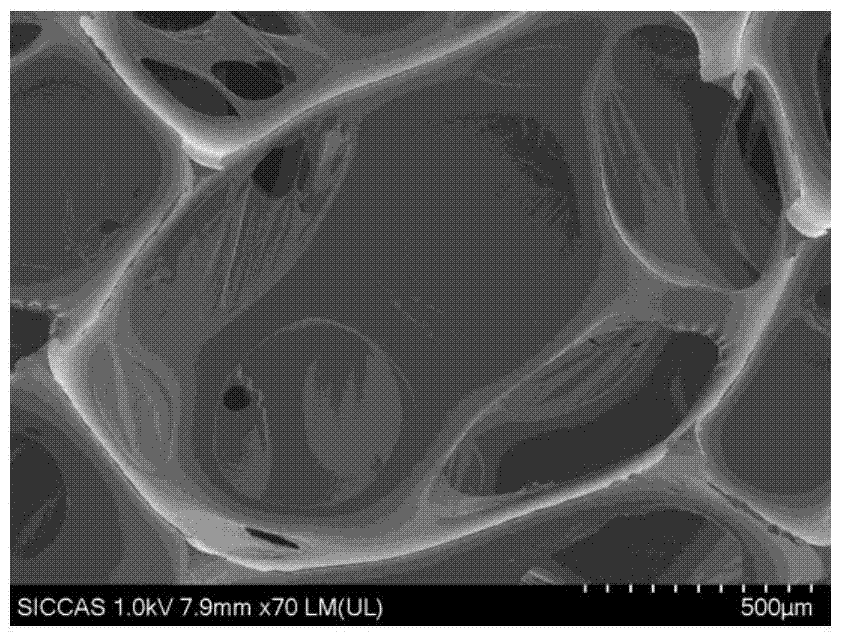

A technology of foam stabilizer and polyurethane, applied in the application of foam stabilizer, the application field of foam stabilizer in the preparation of polyurethane foam products, can solve the problem of affecting the performance of foam stabilizer, affecting the performance of polyurethane foam products, and many by-products, etc. problem, to achieve soft indentation hardness, decrease in indentation hardness, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

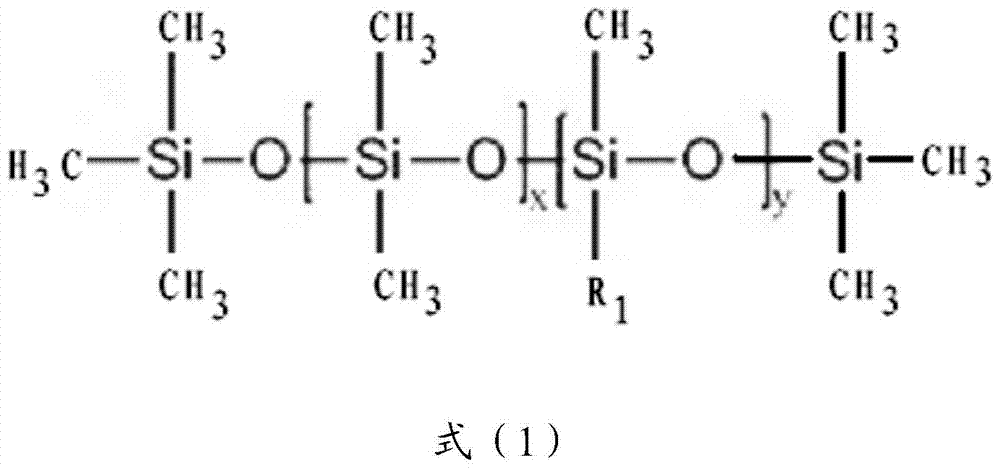

[0057] (1) Mix polyoxyethylene polyoxypropylene ether, acrylic acid, acid catalyst, polymerization inhibitor and water-carrying agent, heat to reflux, control the reaction temperature to 120°C, and the reaction time to 20h, remove the water generated by the reaction at any time during the reaction, Generate an intermediate product, remove the residual acrylic acid in the intermediate product to obtain the desired alkoxypolyoxyethylene polyoxypropylene ether acrylate; wherein m=10, n=100 in the polyoxyethylene polyoxypropylene ether structural formula, R2 is methyl base, the molar ratio of acrylic acid to polyoxyethylene polyoxypropylene ether is 1.5:1, the catalyst is sulfuric acid accounting for 5% of the total mass of polyoxyethylene polyoxypropylene ether and acrylic acid, and the polymerization inhibitor is accounting for polyoxyethylene polyoxypropylene ether 1% of hydroquinone and 1% of the total mass of acrylic acid, and 50% of toluene in the total mass of polyoxyethylen...

Embodiment 2

[0060] (1) Mix polyoxyethylene polyoxypropylene ether, acryloyl chloride, p-toluenesulfonic acid, polymerization inhibitor and water-carrying agent, heat to reflux, control the reaction temperature at 120 ° C, and the reaction time is 22 hours to generate intermediate products, remove the intermediate products residual acryloyl chloride to obtain the required alkoxypolyoxyethylene polyoxypropylene ether acrylate; wherein m=100, n=10 in the structural formula of polyoxyethylene polyoxypropylene ether, R2 is containing ethyl, acryloyl chloride and polyoxypropylene The molar ratio of oxyethylene polyoxypropylene ether is 1.4:1, p-toluenesulfonic acid accounts for 4% of the total mass of polyoxyethylene polyoxypropylene ether and acryloyl chloride, and the polymerization inhibitor is 4% of the total mass of polyoxyethylene polyoxypropylene ether and acryloyl chloride The total mass is 0.8% of tert-butyl hydroquinone, and the water-carrying agent is 40% of cyclohexane accounting for...

Embodiment 3

[0063] (1) Mix polyoxyethylene polyoxypropylene ether, acrylic acid, acid catalyst, polymerization inhibitor and water-carrying agent, heat to reflux, control the reaction temperature at 110°C, and the reaction time is 18h. During the reaction process, use a water separator to remove the reaction at any time. Generated water generates an intermediate product, removes residual acrylic acid in the intermediate product, and obtains the desired alkoxypolyoxyethylene polyoxypropylene ether acrylate; wherein m=80, n=90 in the polyoxyethylene polyoxypropylene ether structural formula , R2 contains propyl group, the molar ratio of acrylic acid and polyoxyethylene polyoxypropylene ether is 1.5:1, the catalyst is a solid-loaded acid accounting for 3% of the total mass of polyoxyethylene polyoxypropylene ether and acrylic acid, and the polymerization inhibitor is The total mass of polyoxyethylene polyoxypropylene ether and acrylic acid is 0.6% of di-tert-butylhydroquinone, and the water-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com