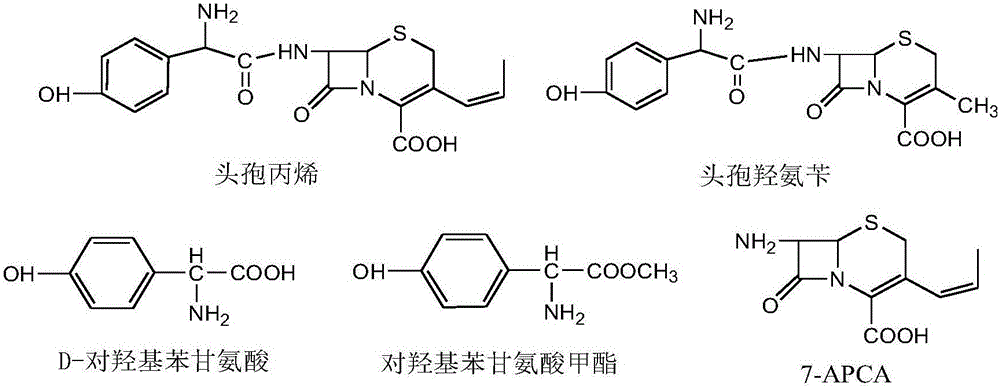

Method for recovering D-p-hydroxyphenylglycine (D-HPG) from cefprozil production waste liquid in enzyme synthesis process

A technology of p-hydroxyphenylglycine and cefprozil, which is applied in the field of medicine, can solve the problems of difficulty in collecting a single substance, and the adsorption effect is greatly affected by multiple factors, and achieve the effect of low processing cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first step, resin pretreatment;

[0035] 201×7 resin (produced by Shandong Lukang Like Pharmaceutical Co., Ltd.) was packed into a column of 30mL, and 5BV of 1mol / L HCl aqueous solution was used to pass through the resin, washed with 4.5BV of deionized water until the pH of the dripping solution was 6, and then 1mol / L 5BV of NaOH aqueous solution to exchange the resin into OH type, and wash with 5.8BV of deionized water until the dripping solution pH=8;

[0036] The second step is the recovery of D-HPG;

[0037] Take 180mL of cefprozil crystallization waste liquid synthesized by enzymatic method at a temperature of 25°C, pass it through a 201×7 resin column at a flow rate of 1BV / h, and drip out 168mL, which can be recycled and applied to the next batch of production;

[0038] The third step, the elution of D-HPG;

[0039] Adopt 3BV deionized water to pass through the resin with a flow rate of less than 2BV / h, wash off the water-soluble residue on the resin; then u...

Embodiment 2

[0042] The first step, resin pretreatment;

[0043]201×7 resin (produced by Shandong Lukang Like Pharmaceutical Co., Ltd.) was packed into a column of 30mL, and 5BV of 1mol / L HCl aqueous solution was used to pass through the resin, washed with 6BV of deionized water until the pH of the dripping liquid was 5, and then 1mol / L of HCl was used to 5BV of NaOH aqueous solution to exchange the resin into OH type, and wash with 6BV of deionized water until the dripping solution pH=7;

[0044] The second step is the recovery of D-HPG;

[0045] Take 180mL of cefprozil crystallization waste liquid synthesized by enzymatic method at a temperature of 23°C, pass it through a 201×7 resin column at a flow rate of 1BV / h, and drop out 175mL, which can be recycled and applied to the next batch of production;

[0046] The third step, the elution of D-HPG;

[0047] Adopt 5BV deionized water to pass through the resin with a flow rate of less than 2BV / h, wash off the water-soluble residue on the r...

Embodiment 3

[0050] The first step, resin pretreatment;

[0051] 201×7 resin (produced by Shandong Lukang Like Pharmaceutical Co., Ltd.) was packed into a column of 30mL, and 5BV of 1mol / L HCl aqueous solution was used to pass through the resin, washed with 4-8BV of deionized water until the pH of the dripping solution was 5, and then 1mol / L 5BV of NaOH aqueous solution of L to exchange the resin into OH type, and wash with 6.4BV of deionized water until the dripping solution pH=8;

[0052] The second step is the recovery of D-HPG;

[0053] Take 180mL of cefprozil crystallization waste liquid synthesized by enzymatic method at a temperature of 23°C, pass it through a 201×7 resin column at a flow rate of 1BV / h, and drop out 172mL, which can be recycled and applied to the next batch of production;

[0054] The third step, the elution of D-HPG;

[0055] Use 4BV deionized water to pass through the resin at a flow rate of less than 2BV / h to wash off the water-soluble residue on the resin; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com