Drying and anti-mildew bactericide for garments

An anti-mildew fungicide and drying technology, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of no drying effect and no sterilization function, and achieve the effects of superior drying, improved product performance, and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

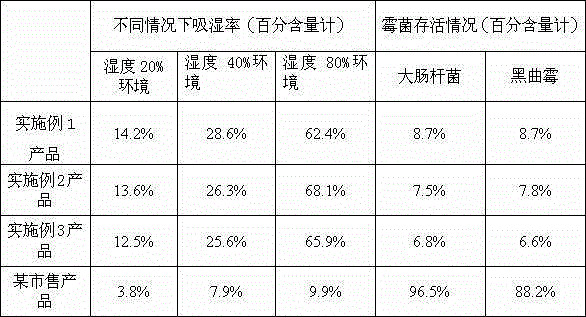

Examples

Embodiment 1

[0037] The clothes drying anti-fungal fungicide in this embodiment is composed of the following components in parts by mass: 28 parts of biguanide trioctylbenzene sulfonate, 30 parts of silthiopyrad, 26 parts of amino oligosaccharide, pentachloride 30 parts of nitrobenzene, 26 parts of antiviral alum, 30 parts of vancomycin, 26 parts of sodium diacetate, 32 parts of tetrabutyl titanate, 26 parts of ammonium perchlorate, 30 parts of ethyl paraben, polyethylene oxide 26 parts of trimethylammonium chloride, 30 parts of dimethyl fumarate, 26 parts of 3-iodo-2-propynyl butyl carbamate, 30 parts of benzimidazole, butyl iodopropynyl carbamate 26 parts of ester, 30 parts of bauxite, 26 parts of potato modified starch, 30 parts of bamboo charcoal powder, 26 parts of lightly burned magnesium oxide, 30 parts of polyacrylamide starch.

[0038]The steps of the preparation method of the above-mentioned garment drying mildew-proof bactericide are as follows:

[0039] (1) The mass fraction o...

Embodiment 2

[0043] The clothing drying anti-fungal fungicide in this embodiment is composed of the following components in parts by mass: 30 parts of biguanide trioctyl benzene sulfonate, 32 parts of silthiopyrad, 28 parts of amino oligosaccharide, pentachloride 32 parts of nitrobenzene, 28 parts of antiviral alum, 32 parts of vancomycin, 28 parts of sodium diacetate, 34 parts of tetrabutyl titanate, 28 parts of ammonium perchlorate, 32 parts of ethyl paraben, polyethylene oxide 28 parts of trimethylammonium chloride, 32 parts of dimethyl fumarate, 28 parts of 3-iodo-2-propynyl butyl carbamate, 32 parts of benzimidazole, butyl iodopropynyl carbamate 28 parts of ester, 32 parts of bauxite, 28 parts of potato modified starch, 32 parts of bamboo charcoal powder, 28 parts of lightly burned magnesium oxide, 32 parts of polyacrylamide starch.

[0044] The steps of the preparation method of the above-mentioned garment drying mildew-proof bactericide are as follows:

[0045] (1) The mass fractio...

Embodiment 3

[0049] The clothing drying anti-fungal bactericide in this embodiment is composed of the following components in parts by mass: 32 parts of biguanide trioctylbenzene sulfonate, 34 parts of silthiopyrad, 30 parts of amino oligosaccharide, 30 parts of pentachloride 34 parts of nitrobenzene, 30 parts of antiviral alum, 34 parts of vancomycin, 30 parts of sodium diacetate, 36 parts of tetrabutyl titanate, 30 parts of ammonium perchlorate, 34 parts of ethyl paraben, polyethylene oxide 30 parts of trimethylammonium chloride, 34 parts of dimethyl fumarate, 30 parts of 3-iodo-2-propynyl butyl carbamate, 34 parts of benzimidazole, butyl iodopropynyl carbamate 30 parts of ester, 34 parts of bauxite, 30 parts of potato modified starch, 34 parts of bamboo charcoal powder, 30 parts of lightly burned magnesium oxide, 34 parts of polyacrylamide starch.

[0050] The steps of the preparation method of the above-mentioned garment drying mildew-proof bactericide are as follows:

[0051] (1) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com