Spray pipe for high-temperature diffusion furnace and application thereof

A technology of high-temperature diffusion and spray pipes, which is applied in the field of spray pipes, can solve problems such as the inability to adjust and improve the size and uniformity of the sheet resistance, the large difference in the size of the sheet resistance of the diffusion layer, and the inability to control the thickness of dead settling well. Achieve the effect of eliminating the short board effect, maintaining the uniformity in the silicon wafer, and good uniformity in the silicon wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An application example of the gas diffusion spray pipe prepared in the present invention, using P-type 156 monocrystalline silicon wafer as the base material, the specific steps of the use method are as follows:

[0033] (1) Make 800 P-type 156 monocrystalline silicon wafers into texturing;

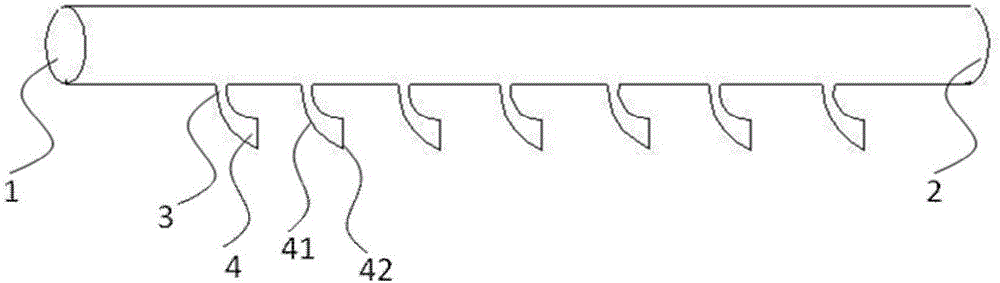

[0034] (2) Diffusing the monocrystalline silicon wafers in a tube diffusion furnace; divide the 156 monocrystalline silicon wafers into 2 groups, each with 400 wafers, among which group A will be diffused with a conventional tail gas diffusion furnace tube, and B The team used the diffusion furnace tube with tail gas inlet and gas diffusion spray tube in the present invention (take n=1, and its structure diagram is as figure 2 (Shown) perform diffusion. After this step, samples are taken in two groups to measure the sheet resistance of the silicon wafer after diffusion;

[0035] (3) Wet etch the silicon wafer after diffusion and polish the back surface;

[0036] (4) Use aluminum oxide and...

Embodiment 2

[0047] An application example of the gas diffusion spray pipe prepared in the present invention, using P-type 156 monocrystalline silicon wafer as the base material, the specific steps of the use method are as follows:

[0048] (1) Texture 1000 P-type 156 monocrystalline silicon wafers;

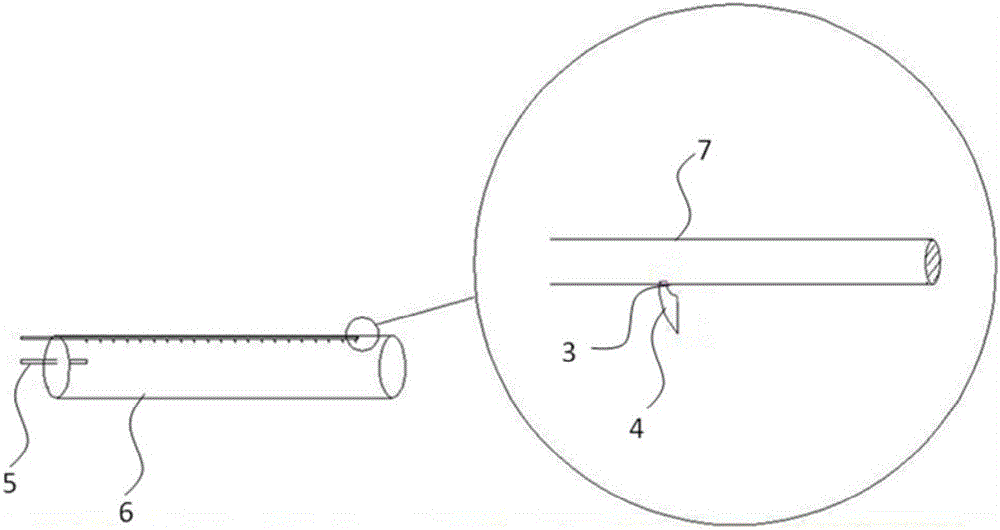

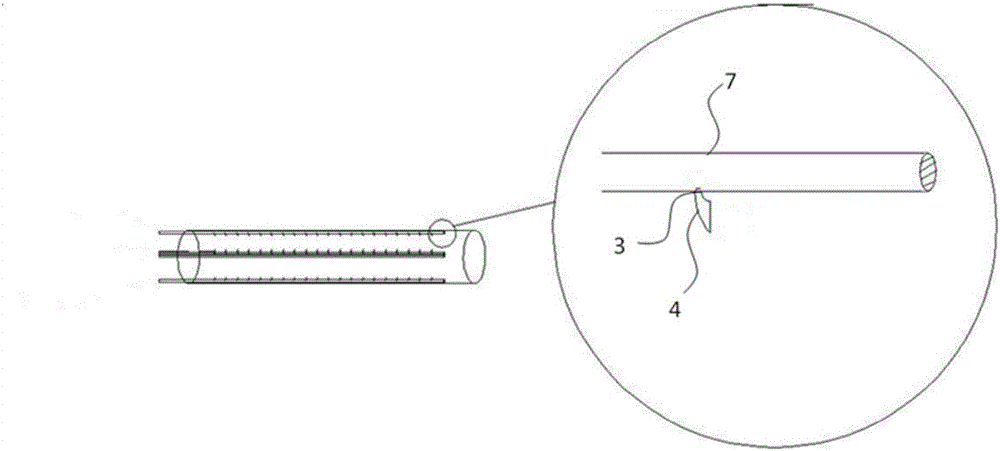

[0049] (2) Diffusing the monocrystalline silicon wafers in a tubular diffusion furnace; divide the 156 monocrystalline silicon wafers into 2 groups, 500 pieces in each group, among which group A uses the conventional tail air intake and spray air diffusion furnace The tube diffuses. Team B uses the diffusion furnace tube of the present invention with a tail air intake and a new spray tube (take n=4, and its structure diagram is as image 3 (Shown) perform diffusion. After this step, samples are taken in two groups to measure the sheet resistance of the silicon wafer after diffusion;

[0050] (3) Wet etch the silicon wafer after diffusion and polish the back surface;

[0051] (4) Use aluminum oxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com