A metal powder-cored seamless flux-cored wire for fillet welding

A technology of seamless flux-cored welding wire and powder-cored welding wire, which is applied in the field of metal powder-cored seamless flux-cored welding wire for fillet welding of low-alloy steel, can solve the problems such as failure to achieve, and achieve less slag and good welding processability. , the effect of improving electrical conductivity

Active Publication Date: 2017-09-29

725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Chinese patent, the publication number is CN101323057A, and the publication date is December 17, 2008. The patent name is a kind of high-strength metal core type seamless flux-cored welding wire. A seamless flux-cored wire for welding low-alloy steel with a yield strength exceeding 785MPa is disclosed. The welding metal strength given in the examples exceeds 785Mpa, but does not meet the requirement of 890MPa

[0005] After searching, it is found that there is no relevant method for using 100% CO2 gas shielding, which is suitable for transverse fillet welding of steel plates with primer Disclosed Technology of Metal Powder Core Type Seamless Flux-Cored Welding Wire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

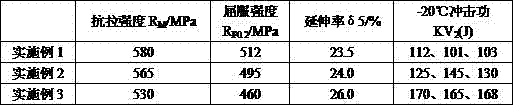

[0046] Embodiments 1, 2, and 3 are metal powder-cored seamless flux-cored wires suitable for high-speed transverse fillet welding of steel plates with primers, and are filled with powder in the steel pharmaceutical skin, and the weight of the filled powder accounts for 10 to 25% of the total weight of the welding wire. %.

[0047] Raw material name

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a metal powder core-type seamless flux-cored wire for angle welding. Flaws are prevented by reducing the content of diffusible hydrogen in weld metal and reducing the content of slag formers in the formula of the flux-cored wire. The metal powder core-type seamless flux-cored wire has good anti-porosity property when used for transverse angle welding of a primer steel plate and has good low temperature impact toughness while the -20 DEG C impact energy average value can be up to 47 J. The metal powder core-type seamless flux-cored wire has good welding manufacturability, is stable in electric arc during welding, can form spray transfer easily, is easy to operate, is good in weld appearance and generates a little slag. The surface of the flux-cored wire can be plated with copper, so that the electric conductivity is improved. Wire feeding is stable, automatic welding is facilitated, and the diffusible hydrogen of deposited metal is smaller than 4 ml / 100g.

Description

【Technical field】 [0001] The invention relates to the field of welding materials, in particular to a metal powder-cored seamless flux-cored wire for fillet welding, in particular to a flux-cored wire adapted to use 100% CO 2 Metal powder cored seamless flux cored wire for gas shielded welding inorganic zinc primer and phosphoric acid primer for fillet welding of low alloy steel. 【Background technique】 [0002] It is known that with the wide application of flux-cored wires in ships, bridges and other industries, in the fillet welded joints of welded components, the trend of using flux-cored wires for semi-automatic welding, desktop automatic welding and welding machinery automation is strengthened. However, in general, in order to prevent the steel plate from rusting, it is necessary to pre-coat the steel plate with a primer, and most of them are inorganic zinc primer and phosphoric acid primer. When the general flux-cored wire is used for the transverse fillet welding of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K35/368B23K9/16B23K35/30

CPCB23K9/16B23K35/0266B23K35/3073B23K35/3608B23K35/368

Inventor 张晓朱官朋冯兆龙

Owner 725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com