Filtering material for mask filtering layer and mask

A filter layer and filter material technology, applied in the field of sanitary products, can solve the problems of increased exhalation and inhalation resistance, difficulty in removing tiny particles, transmission or inhalation into the human body, etc., achieve low exhalation and inhalation resistance, and inhibit bacteria The effect of propagation and propagation, enhancing the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

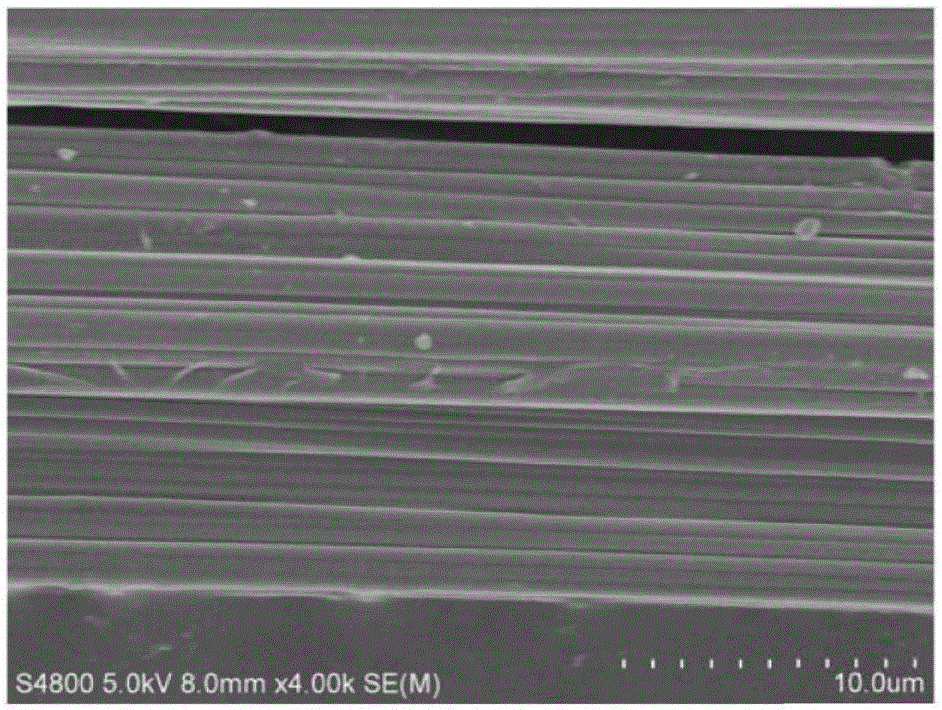

[0028] Embodiment 1: Preparation of activated carbon anion copper alginate fiber

[0029] Stock solution preparation: first add 0.08% mass fraction of activated carbon and 0.08% mass fraction of negative ion powder into water at 60°C, after stirring and dispersing evenly, add 3.84% mass fraction of sodium alginate with characteristic viscosity of 450mPa.s under stirring state, and mix thoroughly After stirring, dispersing and dissolving, filtering, defoaming, and standing still, the spinning stock solution with a viscosity of 8800 mPa.s was prepared.

[0030] Spinning: The stock solution is metered by a metering pump, and then enters the spinneret (cap) through a candle filter and a connecting pipe; the stock solution squeezed out from the holes on the spinneret enters the coagulation bath for coagulation. The first step coagulation solution is CaCl with a concentration of 3.2-4.5% by mass 2 solution, at 40-55°C, the stock solution is coagulated to form primary fibers of ac...

Embodiment 2

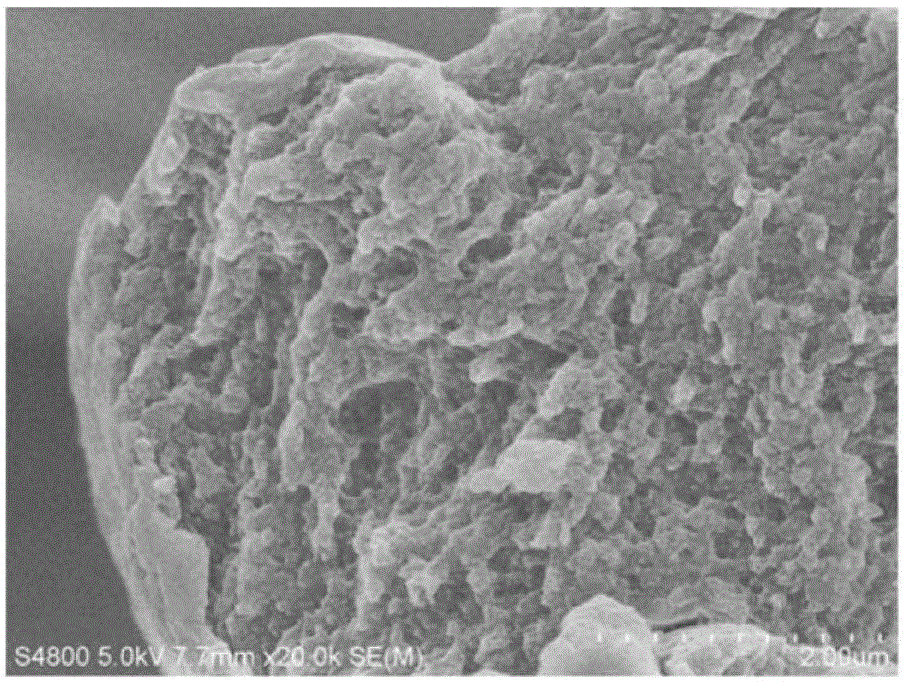

[0032] Embodiment 2: the preparation of negative ion copper alginate fiber

[0033] Stock solution preparation: first add 0.08% mass fraction of negative ion powder into water at 60°C, after stirring and dispersing evenly, add 3.84% mass fraction of sodium alginate with characteristic viscosity of 450mPa.s under stirring, fully mix, stir, disperse and dissolve, then filter, Degassing and standing to prepare spinning dope with a viscosity of 8800mPa.s.

[0034] Spinning: the stock solution is metered by a metering pump, and then enters the spinneret (cap) through a candle filter and a connecting pipe; the fine stream of the stock solution pressed out from the holes on the spinneret enters the coagulation bath for coagulation. The first step coagulation solution is CaCl with a concentration of 3.2-4.5% by mass 2 solution, at 40-55°C, the stock solution is coagulated to form primary fibers of activated carbon anion calcium alginate; the second-step coagulation solution is CuCl...

Embodiment 3

[0036] Embodiment 3: the preparation of mask

[0037] The activated carbon anion copper alginate fiber obtained in Example 1 is prepared into a non-woven filter material with a spunlace non-woven fabric process, and the filter material should have no obvious penetration holes, and the gram weight is 40g / m 2 . Cut the filter material, attach the hot-rolled non-woven fabric surface layer used in conventional masks on one side as the outer layer, and attach the hot-rolled non-woven fabric lining used in conventional masks on the other side as the inner layer, and the filter material layer is in the middle to form a sandwich structure , plus accessories such as nose pads, ear straps, etc., are sewn into a mask.

[0038] Effect verification: The activated carbon anion copper alginate antibacterial mask obtained in Example 1 is used to test according to the national standard GB19083-2010. The mask prepared in this example meets the technical requirements, the filtration efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com