Liquid nitrogen container leak detection system and method

A liquid nitrogen and leak detection technology, which is applied in the direction of detecting the appearance of fluid at the leak point and using the liquid/vacuum degree for liquid tightness measurement, etc., to achieve the effect of low cost, good detection effect and good elegance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

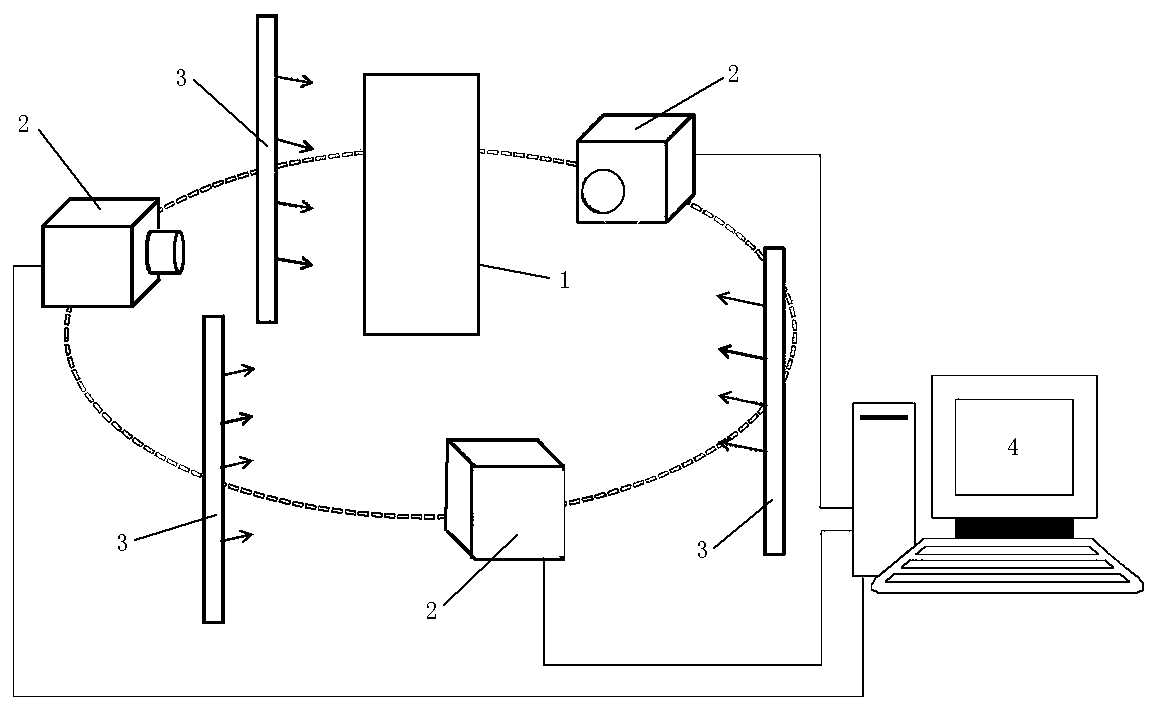

[0036] refer to figure 1 , a liquid nitrogen container leak detection system, comprising a liquid nitrogen container body 1, a video camera 2 and an ultraviolet light source 3, the cavity of the liquid nitrogen container body 1 has liquid nitrogen with a composite fluorescent agent microporous material, so The composite fluorescent agent microporous material is uniformly suspended and dispersed in liquid nitrogen. The composite fluorescent agent microporous material is prepared by uniformly dispersing ultraviolet fluorescent agent particles in a microporous carrier. The pore diameter of the microporous carrier is 10-500 nm. The camera 2 and the ultraviolet light source 3 are distributed around the liquid nitrogen container body 1 .

[0037] The microporous carrier is a polyvinylidene fluoride microporous material, and the composite fluorescent agent microporous material is prepared by the following steps:

[0038] (1) Dibutyl phthalate and dodecanol are prepared as a mixed so...

Embodiment 2

[0045] refer to figure 1 , a liquid nitrogen container leak detection system, comprising a liquid nitrogen container body 1, a video camera 2 and an ultraviolet light source 3, the cavity of the liquid nitrogen container body 1 has liquid nitrogen with a composite fluorescent agent microporous material, so The composite fluorescent agent microporous material is uniformly suspended and dispersed in liquid nitrogen. The composite fluorescent agent microporous material is prepared by uniformly dispersing ultraviolet fluorescent agent particles in a microporous carrier. The camera 2 and the ultraviolet light source 3 are distributed in the liquid nitrogen Around the container body 1.

[0046] The microporous carrier is an activated carbon microporous material, and the composite fluorescent agent microporous material is prepared by the following steps:

[0047] (1) Activated carbon is homogeneously pulverized, and the particle size is controlled below 300 mesh;

[0048](2) Mix ac...

Embodiment 3

[0052] refer to figure 1 , a liquid nitrogen container leak detection system, comprising a liquid nitrogen container body 1, a video camera 2 and an ultraviolet light source 3, the cavity of the liquid nitrogen container body 1 has liquid nitrogen with a composite fluorescent agent microporous material, so The composite fluorescent agent microporous material is uniformly suspended and dispersed in liquid nitrogen. The composite fluorescent agent microporous material is prepared by uniformly dispersing ultraviolet fluorescent agent particles in a microporous carrier. The camera 2 and the ultraviolet light source 3 are distributed in the liquid nitrogen Around the container body 1.

[0053] The microporous carrier is a perlite microporous material, and the composite fluorescent agent microporous material is prepared by the following steps:

[0054] (1) Expanded perlite is homogeneously crushed, and the particle size is controlled below 300 mesh;

[0055] (2) Mix perlite with u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com