A corrosion-resistant high-strength support and hanger assembly and its manufacturing process

A manufacturing process and high-strength technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that affect the normal and practical use of pipelines, easy loosening and displacement of pipe clamps, corrosion and aging of pipe clamps, etc., and it is not easy to achieve Effects of partial cracking, low work hardening, and no surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

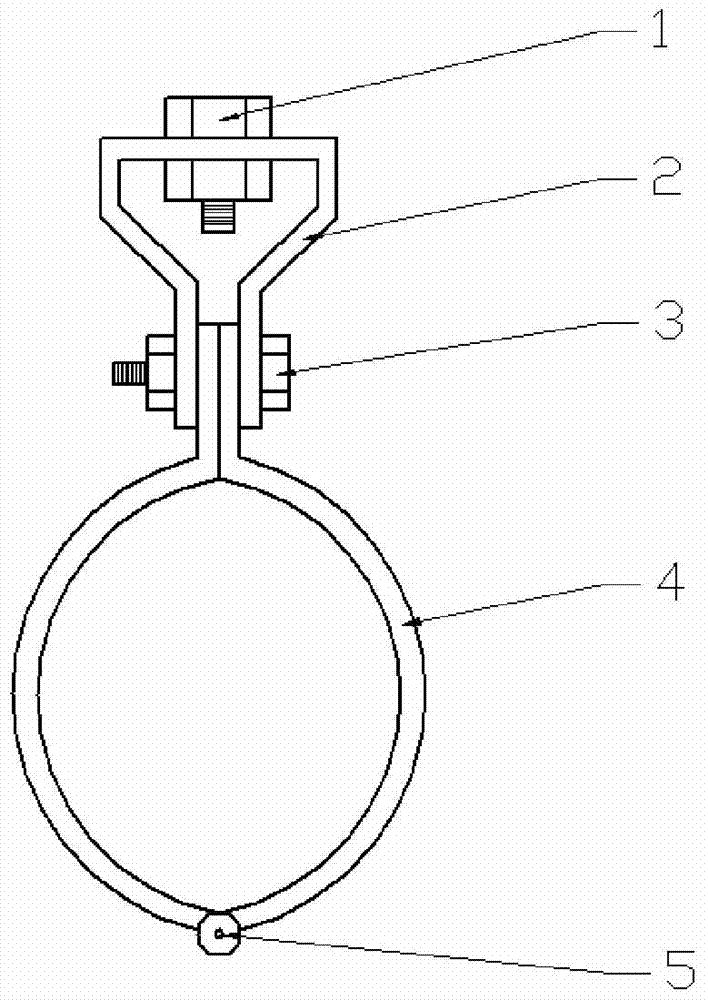

[0029] A corrosion-resistant high-strength support and hanger assembly provided in this embodiment has a structure such as figure 1 As shown, it includes a pipe clamp 4 and a connecting portion 5 arranged at the lower end of the pipe clamp 4. The pipe clamp 4 includes two clamps with the same shape and arranged symmetrically. The clamps include a connecting end, a circular arc segment and a clamping segment , the connecting ends of the two clamps are rotated and connected together, the arc openings of the two clamps are set opposite to each other, the clamping sections of the two clamps are respectively provided with fastening holes, and the positions of the two fastening holes correspond to ;

[0030] The outside of the two clamping sections is provided with a fixed bracket 2, the fixed bracket 2 includes a fixed part and a clamping part, the fixed part is a pull ring with one side opening, the upper end of the pull ring is provided with a fixing hole, and the two sides of th...

Embodiment 2

[0034] The manufacturing process of a corrosion-resistant high-strength support and hanger assembly provided in this embodiment, the processing process of the pipe clamp 4 is as follows:

[0035] Step 1: The composition and mass percentage of the selected steel plate blank are:

[0036] C: 0.03%, B: 0.045%, Mn: 0.32%, Si: 0.101%, P: 0.001%, S: 0.001%, Nb: 0.05%, V: 0.022%, W: 0.015%, Ti: 0.28%, Al: 0.54%, Cu: 0.084%, Ni: 0.71%, Cr: 4.13%, Mo: 0.21%, Lanthanum: 0.015%, Cerium: 0.007%, Neodymium: 0.001%, the balance is Fe and unavoidable impurities;

[0037] Step Two: Rolling:

[0038] The rough rolling temperature is 1270°C, the finish rolling temperature is 960°C, and the final rolling temperature is 830°C. After hot rolling, the steel plate is cooled to 580°C with a cooling rate of 10°C / s, and then air-cooled. Cool the steel plate to 330°C at a cooling rate of 6°C / s, and finally use water cooling to cool the steel plate to room temperature at a cooling rate of 3°C / s;

[00...

Embodiment 3

[0045] The manufacturing process of a corrosion-resistant high-strength support and hanger assembly provided in this embodiment, the processing process of the pipe clamp 4 is as follows:

[0046] Step 1: The composition and mass percentage of the selected steel plate blank are:

[0047] C: 0.05%, B: 0.047%, Mn: 0.34%, Si: 0.103%, P: 0.002%, S: 0.003%, Nb: 0.07%, V: 0.026%, W: 0.019%, Ti: 0.31%, Al: 0.58%, Cu: 0.086%, Ni: 0.75%, Cr: 4.15%, Mo: 0.23%, Lanthanum: 0.017%, Cerium: 0.009%, Neodymium: 0.003%, the balance is Fe and unavoidable impurities;

[0048] Step Two: Rolling:

[0049]The rough rolling temperature is 1290°C, the finish rolling temperature is 980°C, and the final rolling temperature is 850°C. After hot rolling, the steel plate is cooled to 620°C at a cooling rate of 12°C / s, and then air-cooled. Cool the steel plate to 350°C at a cooling rate of 8°C / s, and finally use water cooling to cool the steel plate to room temperature at a cooling rate of 6°C / s;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com