Preparation method of 3-alkoxy alkyl propionate

A technology of alkyl alkoxy propionate and alkyl acrylate, applied in the field of preparation of alkyl 3-alkoxy propionate, can solve the problem of low yield of alkyl 3-alkoxy propionate , Unfriendly environment, high production cost and other problems, to achieve the effect of increasing utilization efficiency, reducing production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

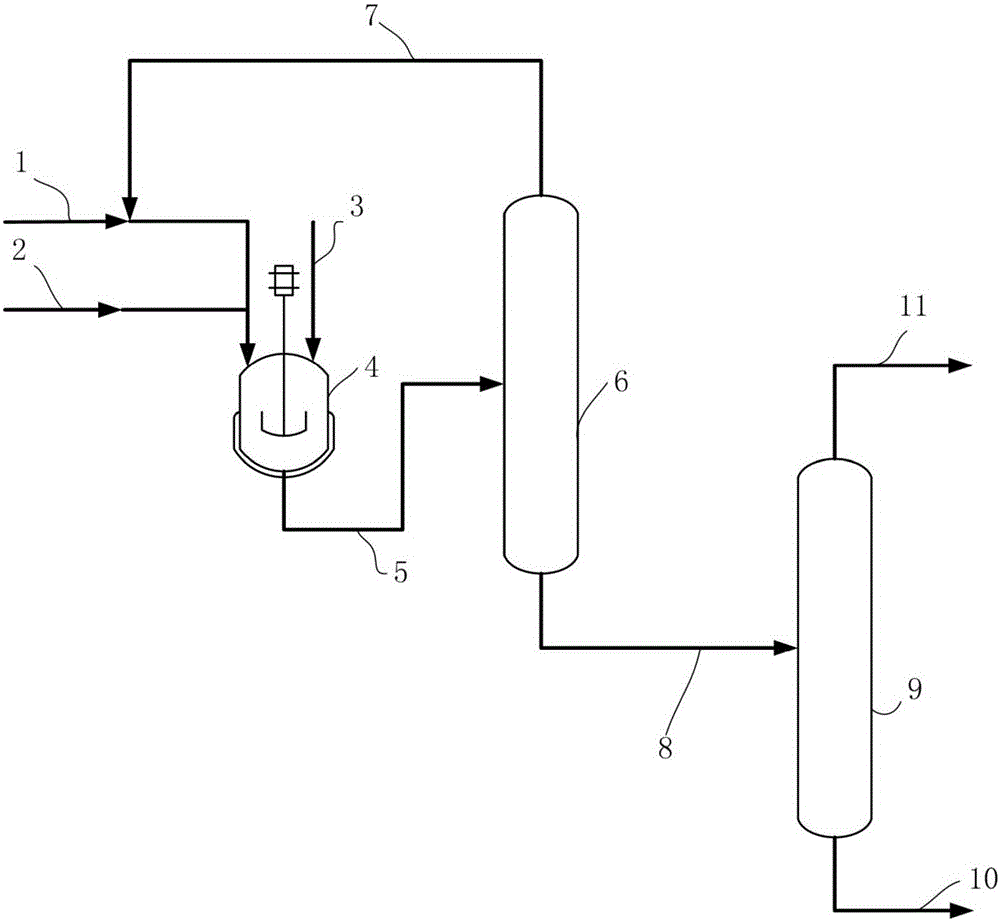

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 10kg of sodium methoxide in 200kg of methanol, add 20kg of MCM-41 into the above alcohol solution, and add toluene of the same mass as the alcohol at the same time, stir and reflux for 2 hours under a nitrogen atmosphere; After washing 3 times, the obtained solid material was vacuum-dried at 80° C. for 5 h to obtain a solid base catalyst with a sodium methoxide content of 50% (the sodium methoxide content is the mass ratio of sodium methoxide to carrier MCM-41).

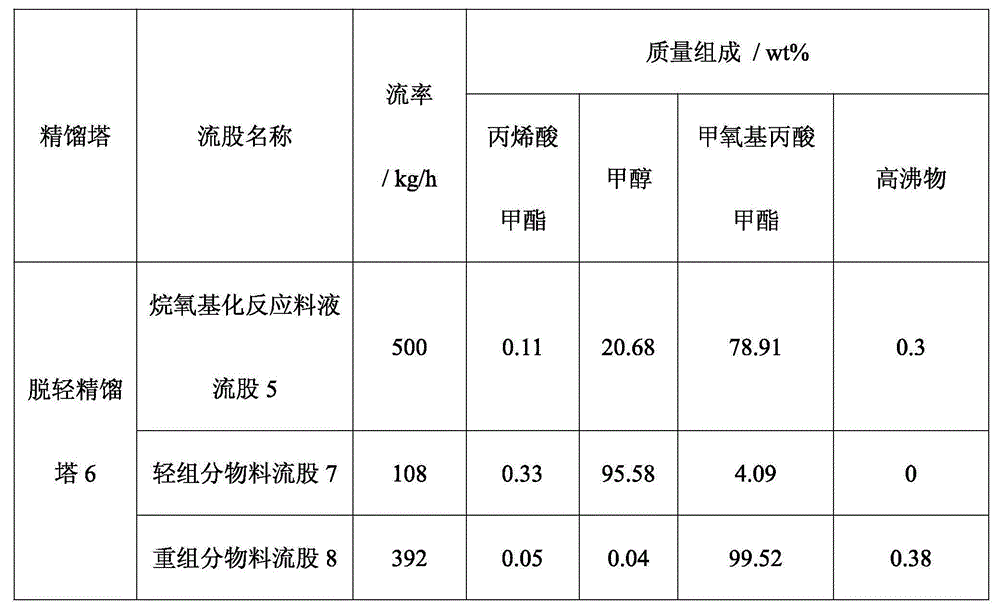

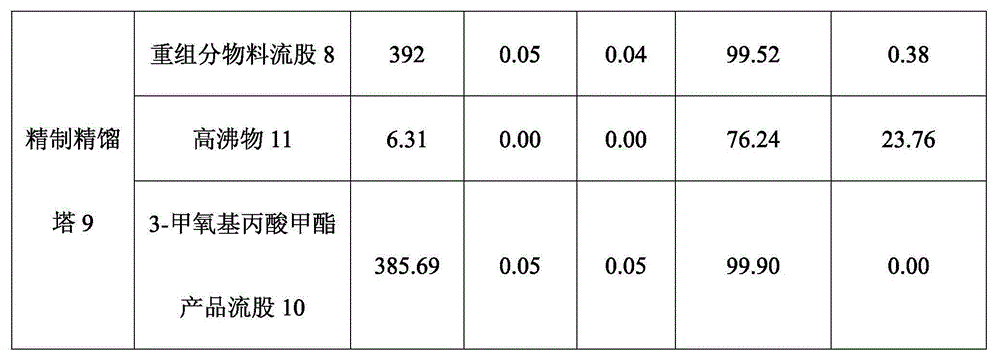

[0033] at 3m 3In the alkoxylation reactor, add 1200kg of fresh methyl acrylate, 893kg of fresh methanol, 6kg of 50% sodium methoxide catalyst loaded on MCM-41, and react at 30°C for 2h. After the reaction, filter the catalyst, and the reaction product passes through the gas phase Chromatographic analysis shows that the mass composition of methyl acrylate, methyl alcohol, methyl 3-methoxypropionate and high boilers are 0.11%, 20.68%, 78.91% and 0.3% respectively, and the conversion rate of methyl acryl...

Embodiment 2

[0040] Dissolve 10kg of potassium methoxide in 100kg of methanol, add 100kg of SBA-15 into the above alcohol solution, and add toluene of the same mass as the alcohol at the same time, stir and reflux for 2 hours under a nitrogen atmosphere; After washing 3 times, the obtained solid matter was vacuum-dried at 80° C. for 5 h to obtain a solid base catalyst with a potassium methoxide content of 10% (the potassium methoxide content is the mass ratio of potassium methoxide to carrier SBA-15).

[0041] at 3m 3 In the alkoxylation reactor, add fresh methyl acrylate 1780kg, fresh methanol 268.1kg, and reclaim the mixture of methyl acrylate and methanol 429.2kg, wherein methyl acrylate 20kg, methanol 401.9kg, total methyl acrylate, methanol The dosage is 1800kg and 676kg respectively. 27kg of 10% potassium methylate catalyst loaded on SBA-15 was reacted at 80°C for 0.2h. After the reaction was over, the catalyst was filtered out, and the reaction product was analyzed by gas chromatog...

Embodiment 3

[0048] Dissolve 20kg of potassium ethoxide in 700kg of absolute ethanol, add 100kg of ZSM-5 to the above alcohol solution, add toluene at the same time as the alcohol, stir and reflux for 2 hours under a nitrogen atmosphere; after the reflux, cool to room temperature, and use After 100kg of toluene was washed 3 times, the obtained solid matter was vacuum-dried at 80° C. for 5 h to obtain a solid base catalyst with a potassium ethylate content of 20% (the potassium ethylate content is the mass ratio of potassium ethylate to carrier ZSM-5).

[0049] at 5m 3 In the alkoxylation reactor, add 2000kg of fresh ethyl acrylate, 40kg of 20% potassium ethoxide catalyst loaded by ZSM-5, and drop 1288kg of fresh ethanol into the reactor at 0°C, and the total dropping time is 4h. After the dropwise addition, the insulation reaction was carried out for 2 hours. After the reaction, the catalyst was filtered out, and the reaction product was analyzed by gas chromatography. The mass composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com