Carbon nanometer ultramicro material large carbon electrode and preparation method thereof

A technology of ultra-fine materials and carbon nanometers, applied in the direction of furnace heating elements, etc., can solve the problems of poor oxidation resistance, poor internal structure, high resistivity, etc., and achieve the effect of improving adsorption performance, improving performance and reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

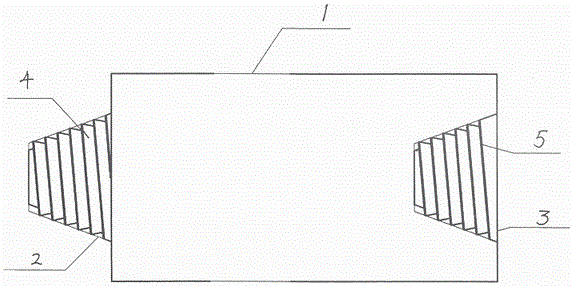

Image

Examples

Embodiment 1

[0038] The first step: medium crushing, sieving, grinding

[0039] The calcined solid raw material is crushed and sieved by electric calcined anthracite, part of the petroleum coke and graphite are crushed and sieved, and part of the ultrafine carbon nano-scale powder is milled with high-efficiency milling equipment;

[0040] Step 2: Ingredients

[0041] According to the described component of claim 1, use the electronic batching system to weigh 8 parts by weight of crushed graphite with a particle diameter greater than 8mm and less than or equal to 16mm, 16 parts by weight of crushed graphite with a particle diameter greater than 4mm and less than or equal to 8mm, and 12 parts by weight of graphite with a particle diameter less than or equal to 4mm. Graphite powder, 8 parts by weight of petroleum coke with a particle size greater than 8 mm and less than or equal to 16 mm, 12 parts by weight of petroleum coke with a particle size greater than 4 mm and less than or equal to 8 m...

Embodiment 2

[0051] The first step: medium crushing, sieving, grinding

[0052] The calcined solid raw material is crushed and sieved by electric calcined anthracite, part of the petroleum coke and graphite are crushed and sieved, and part of the ultrafine carbon nano-scale powder is milled with high-efficiency milling equipment;

[0053] Step 2: Ingredients

[0054] According to claim 1, the component is weighed with an electronic batching system: 12 parts by weight of crushed graphite with a particle diameter greater than 8mm and less than or equal to 16mm, 18 parts by weight of graphite fragments with a particle diameter greater than 4mm and less than or equal to 8mm, 16 parts by weight with a particle diameter of less than or equal to 4mm 12 parts by weight of petroleum coke with a particle size greater than 8 mm and less than or equal to 16 mm, 16 parts by weight of petroleum coke with a particle size greater than 4 mm and less than or equal to 8 mm, 12 parts by weight of petroleum co...

Embodiment 3

[0064] The first step: medium crushing, sieving, grinding

[0065] The calcined solid raw material is crushed and sieved by electric calcined anthracite, part of the petroleum coke and graphite are crushed and sieved, and part of the ultrafine carbon nano-scale powder is milled with high-efficiency milling equipment;

[0066] Step 2: Ingredients

[0067] According to the described component of claim 1, use the electronic batching system to weigh 16 parts by weight of crushed graphite with a particle diameter greater than 8mm and less than or equal to 16mm, 20 parts by weight of crushed graphite with a particle diameter greater than 4mm and less than or equal to 8mm, and 18 parts by weight of graphite with a particle diameter less than or equal to 4mm. Graphite powder, 16 parts by weight of petroleum coke with a particle size greater than 8 mm and less than or equal to 16 mm, 20 parts by weight of petroleum coke with a particle size greater than 4 mm and less than or equal to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com