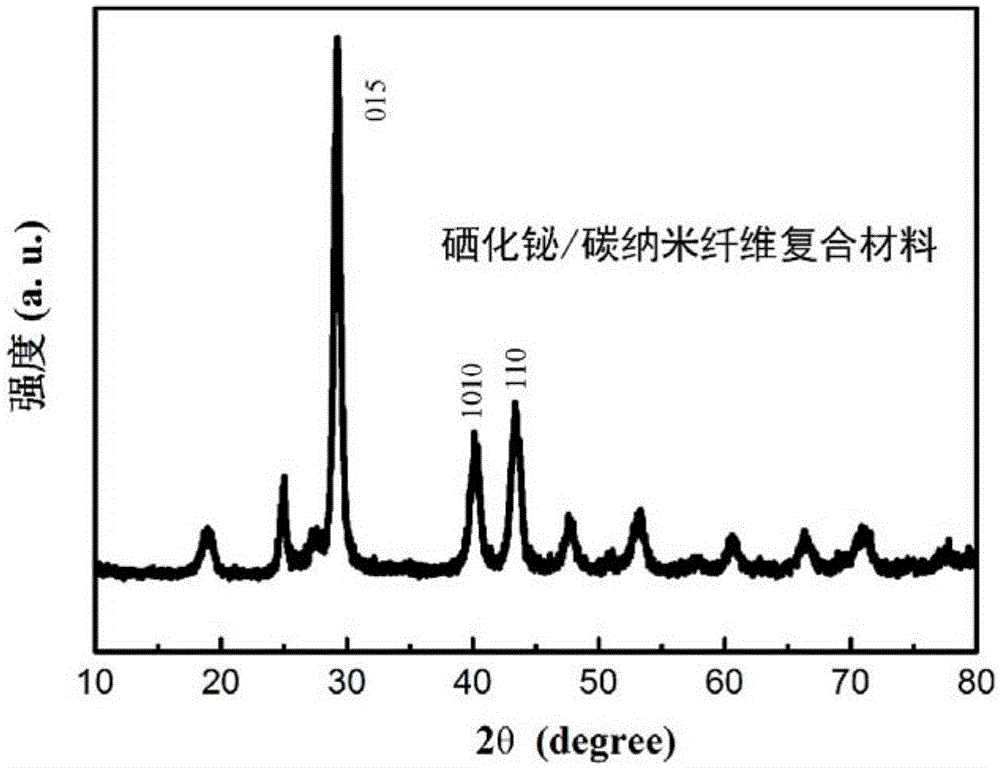

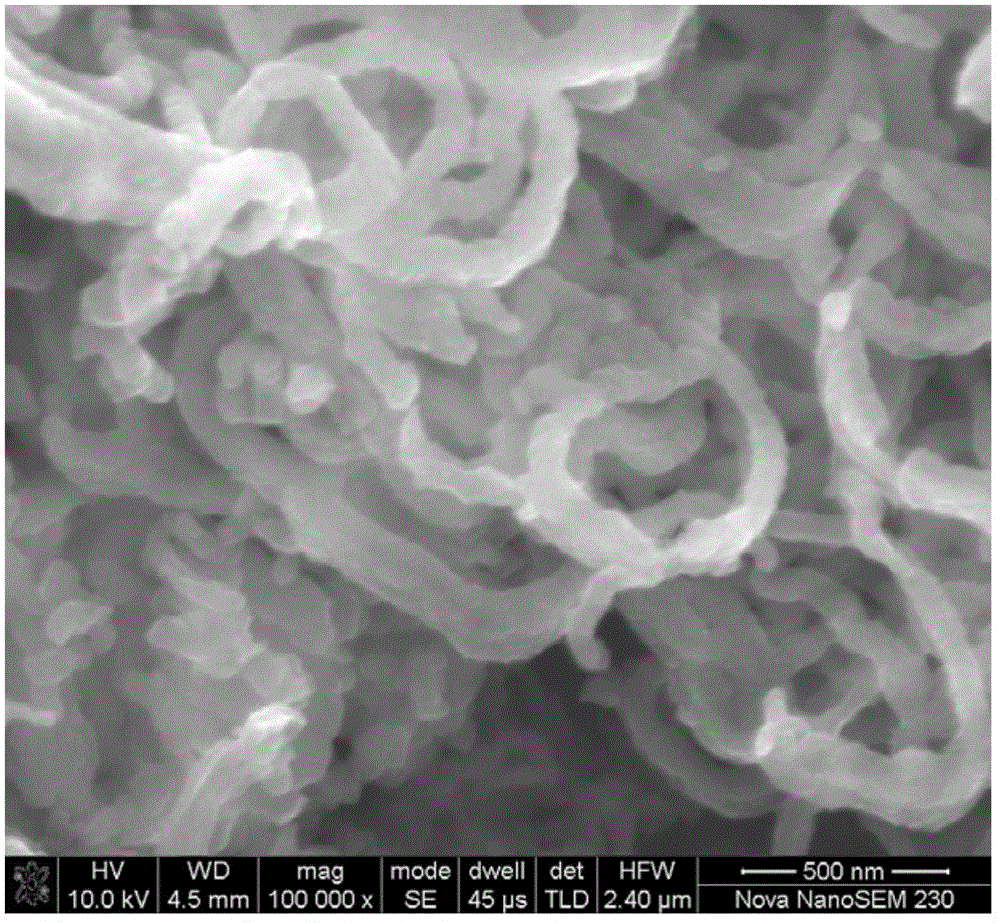

Bismuth selenide/carbon nanofiber composite anode material for sodium ion battery and preparation method thereof

A technology of carbon nanofibers and sodium-ion batteries, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of composite materials without bismuth selenide and carbon nanofibers Material technology and other issues to achieve the effect of low cost, good ion transmission capacity, and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

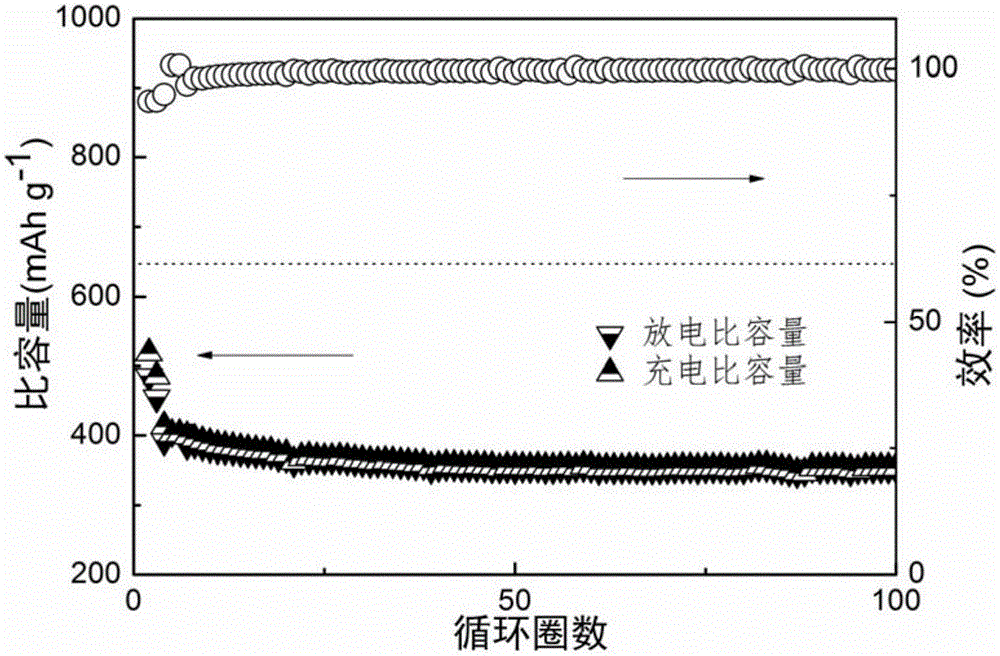

[0037]Get 7.3g of cetyltrimethylammonium bromide (CTAB) and 13.7g of ammonium persulfate (APS) and dissolve in the cooled 120mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 40min, then slowly add 8.3 mL of pyrrole monomer was reacted at 0-5°C for 24 hours, the product was washed with deionized water and hydrochloric acid solution, and dried at 80°C to obtain polypyrrole fibers; take 1g of polypyrrole fibers and 3g of potassium hydroxide and mix them uniformly in an inert atmosphere Under protection, the temperature was raised to 800°C at a heating rate of 5°C / min, and carbon nanofibers were obtained after holding for 3 hours; 0.5g of carbon nanofibers and 0.5g of elemental selenium were evenly mixed, and at a heating rate of 2°C / min, Raise the temperature to 260°C for heat treatment, keep it warm for 12h, take 0.024g product and add it to 40mL bismuth salt solution (1.25g / L), ultrasonic for 30min, 160°C hydrothermal reaction for 10h, the produc...

Embodiment 2

[0045] Take 3.65g of cetyltrimethylammonium bromide (CTAB) and 6.85g of ammonium persulfate (APS) and dissolve them in a cooled 80mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 30min, then slowly add 4.2 mL of pyrrole monomer, react at 0-5°C for 14 hours, wash the product with deionized water and hydrochloric acid solution, and dry at 80°C to obtain polypyrrole fibers; take 1g of polypyrrole fibers and 4g of potassium hydroxide and mix them uniformly, Under protection, the temperature was raised to 1000°C at a heating rate of 5°C / min, and carbon nanofibers were obtained after holding for 2 hours; 0.4g of carbon nanofibers and 0.6g of elemental selenium were evenly mixed, and at a heating rate of 2°C / min, Raise the temperature to 260°C for heat treatment, keep it warm for 12h, take 0.020g product and add it to 40mL bismuth salt solution (1.25g / L), ultrasonic for 40min, 180°C hydrothermal reaction for 12h, the product is washed with deionized wa...

Embodiment 3

[0049] Take 4.87g of cetyltrimethylammonium bromide (CTAB) and 9.13g of ammonium persulfate (APS) and dissolve them in a cooled 100mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 30min, then slowly add 5.53 mL of pyrrole monomer was reacted at 0-5°C for 18 hours, the product was washed with deionized water and hydrochloric acid solution, and dried at 80°C to obtain polypyrrole fibers; take 1g of polypyrrole fibers and 3.5g of potassium hydroxide and mix them uniformly in an inert Under the protection of the atmosphere, the temperature was raised to 900°C at a heating rate of 5°C / min, and carbon nanofibers were obtained after holding for 3 hours; 0.5g of carbon nanofibers and 0.5g of elemental selenium were evenly mixed, and the , after heat treatment at 300°C, keep warm for 10h, take 0.039g product and add it to 40mL bismuth salt solution (2g / L), ultrasonic for 60min, hydrothermal reaction at 160°C for 14h, product washed with deionized water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com