Preparation method of positive ion reaction type environment-friendly fabric stiffening agent

A cationic and reactive technology, applied in the field of textile manufacturing, can solve problems such as low efficiency and waste of energy, and achieve the effects of improving production efficiency, simplifying production processes, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

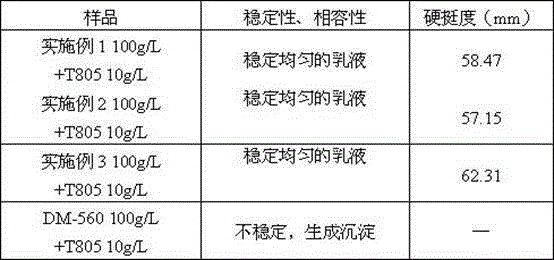

Examples

Embodiment 1

[0017] Add 30.0 g of polycaprolactone diol with a number-average relative molecular weight of 1000 into a 500 mL four-neck flask equipped with a thermometer, a stirrer, and a reflux condenser, raise the temperature to 110°C, and pump at -0.9-1.0 MPa while stirring. Vacuum dehydration for 2h. Cool down to 80°C, add 2.0g of 1,4-butanediol that has been dehydrated and pretreated with 4A molecular sieve, stir evenly, add 35.0g of isophorone isocyanate, and react at 95°C for 2 hours. 6.0g N - Methyldiethanolamine was diluted with 30.0 g butanone, and after the prepolymerization was completed, the temperature was lowered to 70° C., and the mixture was added. After heating up to 70° C. for 3 hours, a polyurethane prepolymer with terminal isocyanate was obtained. Cool down to 60°C and add 11.4g of sodium bisulfite aqueous solution to block for 0.5h, add 3.0g of glacial acetic acid to neutralize for 0.5h, and finally add deionized water to emulsify under the stirring condition of 100...

Embodiment 2

[0019] Add 30.0 g of polytetrahydrofuran ether glycol with a number-average molecular weight of 2000 into a 500 mL four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, raise the temperature to 110°C, and vacuumize at -0.9-1.0 MPa while stirring Dehydration 2h. Cool down to 70°C, add 5.0 g of diethylene glycol that has been dehydrated and pretreated with 4A molecular sieve, stir well, add 24.0 g of diphenylmethane diisocyanate, and react at 80°C for 2 hours. 3.0g N -Methyldiethanolamine was diluted with 30.0 g of acetone, and after the prepolymerization was completed, the temperature was lowered to 50° C., and the mixture was added. After heating up to 55° C. for 3 hours, a polyurethane prepolymer with terminal isocyanate was obtained. Add 10.5g butanone oxime and block at 60°C for 1h, then cool down to 50°C and add 2.3g of glacial acetic acid to neutralize for 0.5h, and finally add deionized water to emulsify under the stirring condition of 1000r...

Embodiment 3

[0021] Add 30.0 g of polybutylene adipate diol with a number-average molecular weight of 3000 into a 500 mL four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, raise the temperature to 110°C, and place it at -0.9- Vacuum dehydration at 1.0MPa for 2h. Cool down to 80°C, add 6.0 g of neopentyl glycol that has been dehydrated and pretreated with 4A molecular sieve, stir well, add 45.0 g of dicyclohexylmethane diisocyanate, and react at 95°C for 2 hours. 8.0g diethanolamine with 40.0g N - dilute with methylpyrrolidone, cool down to 50°C after prepolymerization, and add the mixture. After heating up to 55° C. for 3 hours, a polyurethane prepolymer with terminal isocyanate was obtained. After adding 11.7gε-caprolactam and capping at 80°C for 3h, cool down to 50°C and add 6.9g lactic acid for neutralization for 0.5h, and finally add deionized water to emulsify under the stirring condition of 1000r / min to obtain a cationic capping compound with a solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com