Chrysanthemum ester molecularly imprinted polymer preparing method

A technology of molecular imprinting and polymers, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems that the particle size and uniformity of polymer powder particles are greatly affected by grinding technology, cumbersome operation, and many steps. The effect of low preparation cost, simple preparation process and high enrichment degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Phenothrin Imprinted Polymer Powder

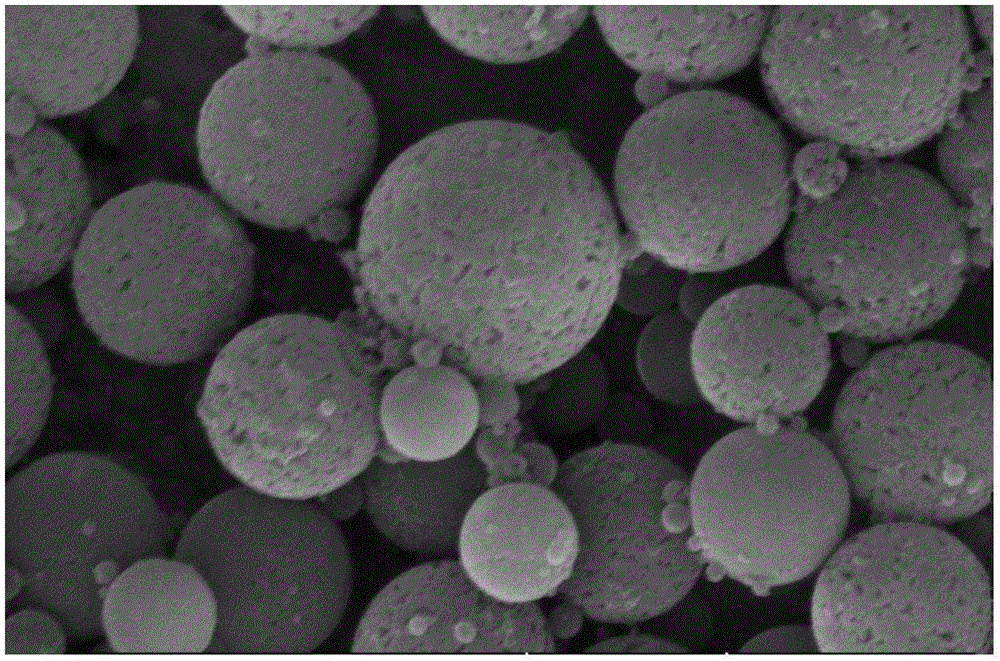

[0031] Take 37.5mL of absolute ethanol, 12.5mL of styrene, 1.0ml of EDMA, 1.0ml of chloroform, 35mg of phenothrin, 0.15g of AIBN, and 0.375g of PVP K-30 in a ground-mouth flask, mix them uniformly by ultrasonic, and aerate with nitrogen 15min, heated and stirred in an oil bath at 70°C with nitrogen gas for 24h, after the reaction was completed, let stand to separate layers, centrifuged to remove the supernatant, and eluted the imprinted polymer of phenothrin with acetic acid / methanol (V / V=1:1) , until no template molecule could be detected in the supernatant, the obtained phenothrin imprinted polymer powder was vacuum-dried at 60°C, and scanned with an electron microscope after drying. Scanned images from the electron microscope, attached figure 1 It can be seen that the phenothrin-imprinted polymer is in the shape of microspheres, and the surface pores are obvious.

Embodiment 2

[0032] Example 2 Preparation of polypermethrin imprinted polymer powder

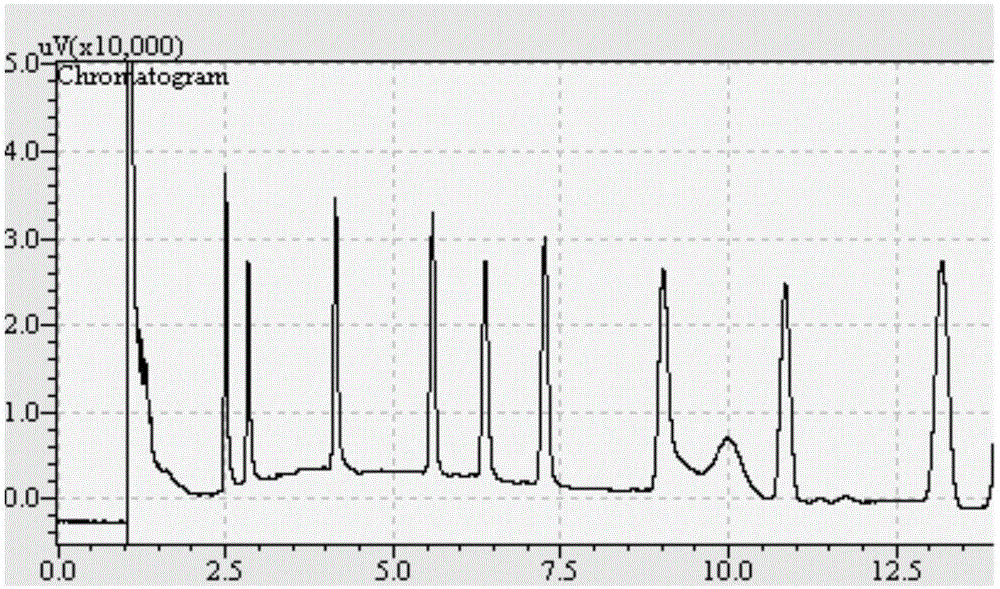

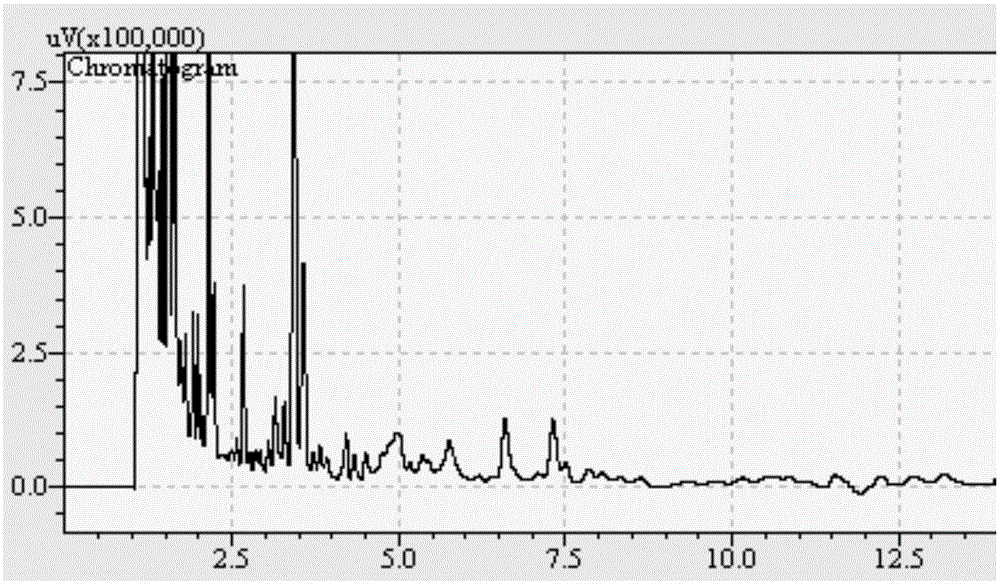

[0033] Take 37.5mL of absolute ethanol, 12.5mL of styrene, 1.0ml of EDMA, 0.75ml of chloroform, 100ug of permethrin, 0.15g of AIBN, and 0.375g of PVP K-30 in a ground-mouth flask, mix them uniformly by ultrasonic, and blow nitrogen Aerate for 15 minutes, heat and stir in an oil bath at 70°C with nitrogen for 24 hours. After the reaction is over, let stand to separate layers, centrifuge to remove the supernatant, and elute the polypermethrin blot with formic acid / ethanol (V / V=1:1) polymer, combined eluents, and the obtained polypermethrin-imprinted polymer powder was vacuum-dried at 60°C. The supernatant after the polymerization reaction is taken, and the content of polypermethrin template molecules in the supernatant is detected by gas chromatography, and the eluate is taken to detect the content of polypermethrin template molecules by gas chromatography. diagram 2-1 It is the gas chromatographic detec...

Embodiment 3

[0034] Example 3 Solid Phase Extraction of Pesticide Residues in Tea with Polymer Powder

[0035] Take by weighing 5g pulverized tea negative sample and add standard solution, add 50mL acetonitrile and shake for 30min to extract, extract with 30000rpm centrifugation for 15min, transfer supernatant, add 0.1g polymer powder (prepared by embodiment 1 or embodiment 2) in the supernatant ), shaken for 30 minutes and mixed well, centrifuged at 3000rpm for 15 minutes, discarded the supernatant, eluted the polymer powder with acetic acid / methanol (V / V=1:1), combined the eluent, concentrated to near dryness with nitrogen blowing, and used petroleum Dilute the volume of ether to 1mL for gas chromatography (GC) detection, and the standard addition recovery rate can reach more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com