Electrode plug manufacturing system and use method thereof

A technology for manufacturing systems and electrode plugs, applied in manufacturing tools, high-frequency current welding equipment, auxiliary devices, etc., can solve the problem that the resistance dispersion of bridge wire resistance has a large influence, will cause electro-optic keratitis, and cannot meet the needs of the market. and other problems, to achieve the effect of facilitating quality control, eliminating the impact on human health, and enhancing international competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

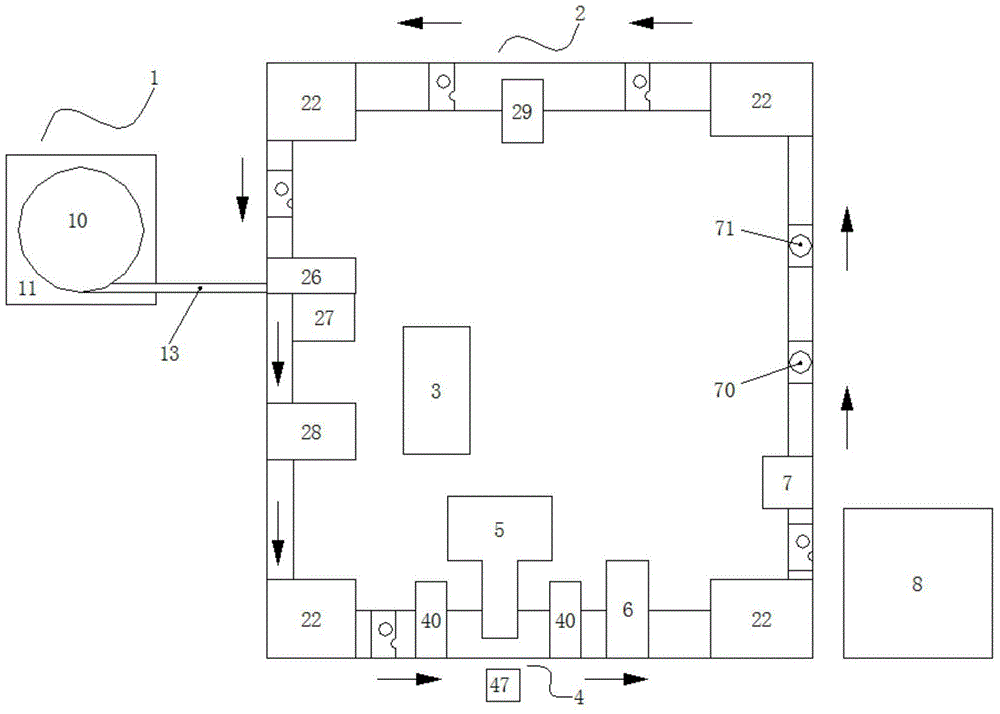

[0082] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

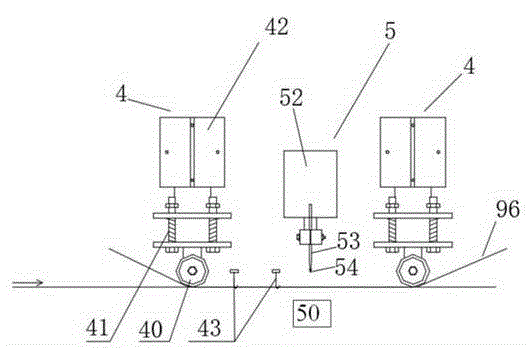

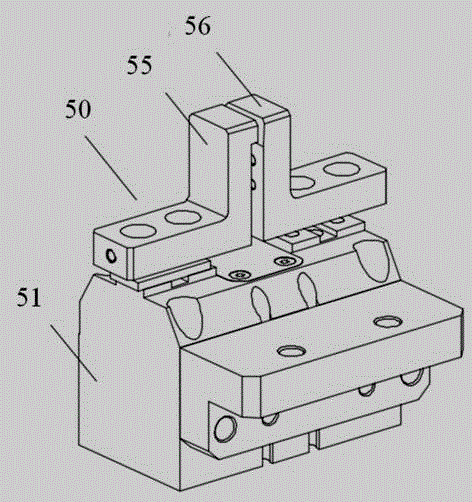

[0083] see Figure 22 , Figure 23 a. Figure 23b, shows the electrode plug to be prepared, including the core electrode 90, the bridge wire 96, the insulating layer 91 and the plug 92 with holes, the core electrode 90 is arranged in the hole of the plug 92, and the core electrode 90 and the plug 92 are provided with The insulating layer 91, the plug 92 is connected with the first electrode needle 93, the core electrode 90 is connected with the second electrode needle 94; the bridge wire 96 is welded with the core electrode 90 and the plug 92, and the bridge wire 96 and the plug 92 have more than two welds. Point 97; set the core electrode 90 inside the plug 92 with a hole, and then ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com