Accumulative roll-bonding preparation method of nanometer lamellar phase enhanced TiNi alloy composite plate

A technology of accumulative stacking and nano-sheets, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the difficulty of melting nano-sheet phase-reinforced TiNi-based composite materials, the distribution of reinforcement phases and the uneven size, etc. problems, to achieve the effect of low equipment requirements, easy regulation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] (1) Put the TiNi shape memory alloy foil in HF, HNO 3 And pickling in a mixed solution of deionized water.

[0029] (2) Polish the Nb foil with metallographic sandpaper to remove surface scale.

[0030] (3) The pickled TiNi shape memory alloy was ultrasonically cleaned in acetone for 15 minutes, and rinsed with alcohol.

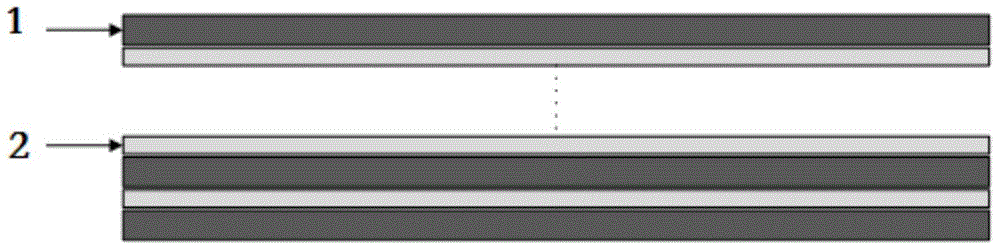

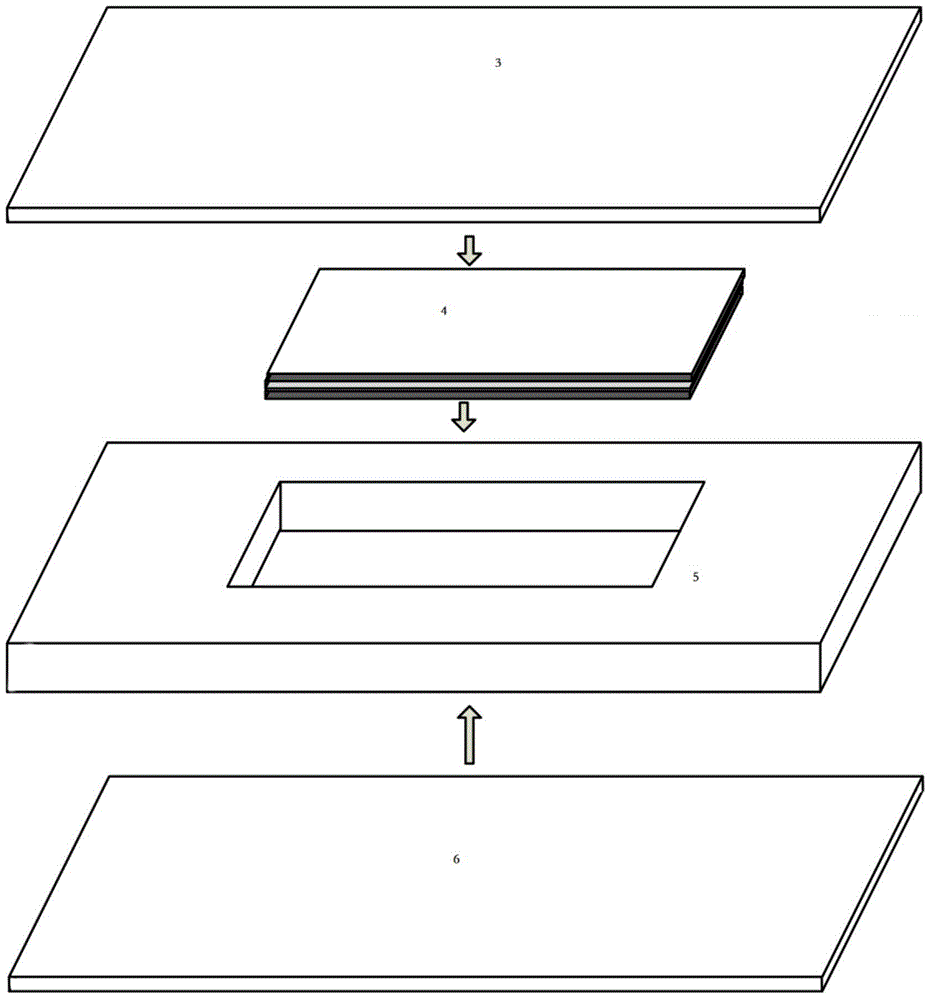

[0031] (4) Alternately stack pickled TiNi-based shape memory alloys and Nb foils and ensure that the outermost layer is a TiNi-based alloy sheet, mechanically fix both ends of the stacked sheet, and use stainless steel on the surface of the fixed sheet wrapping.

[0032] (5) The plate obtained in step (4) is placed under the rolling mill for rolling, the rolling temperature is 400°C-800°C, the heat preservation time for plate heating before rolling is 400°C, and the rolling pass is no more than 32 positive Integer, the deformation amount of a single pass is 50%.

[0033] (6) Vacuum annealing the rolled sheet in the range of 300° C. to 600° C. to ob...

specific Embodiment approach 2

[0034] The difference between this embodiment and Embodiment 1 is that the metal W foil is used in step (2) and step (4) in this embodiment.

specific Embodiment approach 3

[0035] The difference between this embodiment and Embodiment 1 is that the metal Ag foil is used in step (2) and step (4) of this embodiment.

[0036] Finally, it should be noted that the stainless steel sheath in step (5) of the present invention can be replaced by a pure Ti sheath.

[0037] Advantages of the present invention are verified below by examples.

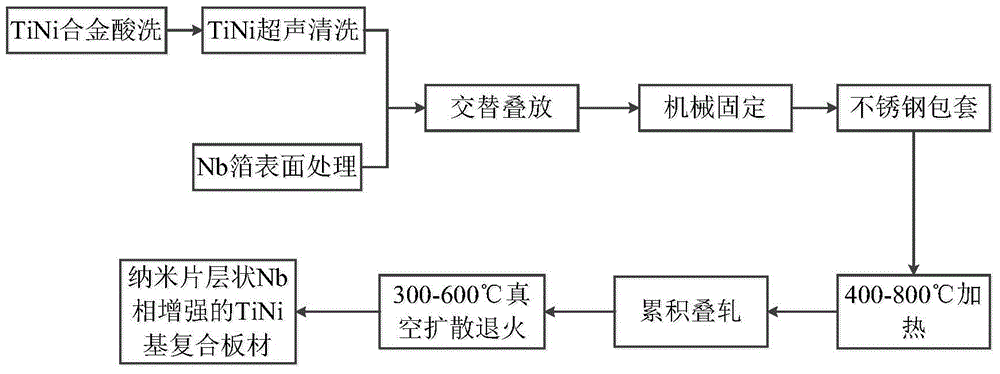

[0038] combine figure 1 , the technical route mainly includes:

[0039] (1) Change the composition to Ti 48.8 Ni 51.2 The shape memory alloy foil is placed in HF, HNO with a volume percentage of 1:2:10 3 And pickling in a mixed solution of deionized water, the final thickness of the foil is 0.6mm.

[0040] (2) Polish the Nb foil with metallographic sandpaper to remove the surface oxide skin, and the final thickness is 0.2 mm.

[0041] (3) The pickled TiNi shape memory alloy was ultrasonically cleaned in acetone for 15 minutes, and rinsed with alcohol.

[0042] (4) Alternately stack pickled TiNi shape memory alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com