A kind of fuel cell catalyst with nano cable as carrier and preparation method thereof

A nano-cable and fuel cell technology, which is applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced catalyst utilization, difficulty in noble metal particles, lack of active sites, etc., and achieves improved stability, Prevents oxidation and corrosion, improves activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking Ag@C nanocables loaded with noble metal Pt as a catalyst as an example, the noble metal loading is 5% for illustration.

[0031] Take 0.25g silver nitrate and 1.1mL glycerin (molar ratio is 1:13, silver nitrate 0.0012mol, glycerin 0.015mol) and add 35mL sulfuric acid solution with a molar concentration of 1mol / L, stir well and transfer to 50mL In a polytetrafluoroethylene reactor, react at 170°C for 10h, cool to room temperature, wash with deionized water and ethanol several times, and dry in vacuum;

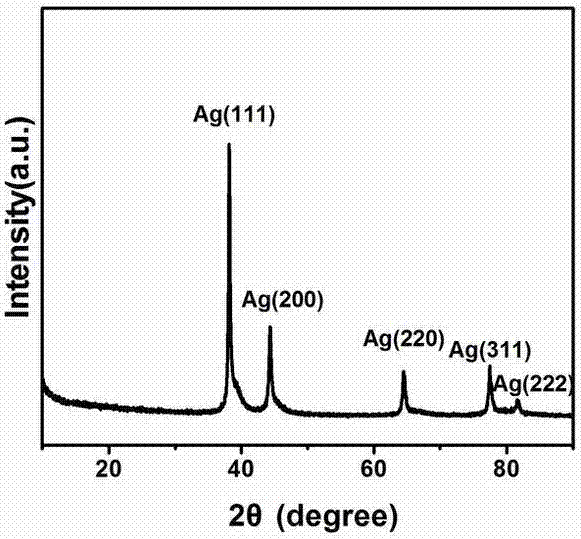

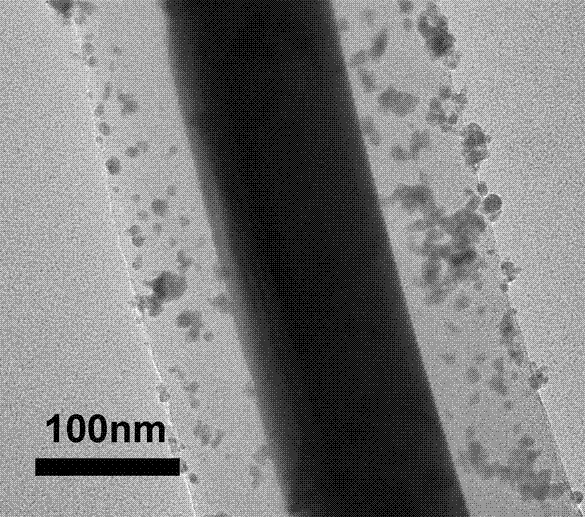

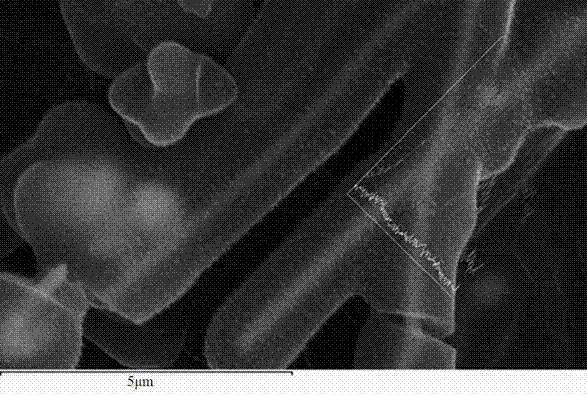

[0032] Put the product into a tubular atmosphere furnace and calcined under the protection of nitrogen at a temperature of 600°C. Add the calcined product to 150 mL of potassium hydroxide solution with a molar concentration of 2 mol / L, and heat to reflux in a boiling water bath for 2 hours. , after cooling down to room temperature, wash with deionized water to neutrality, collect after drying to obtain Ag@C nanocable carrier, figure 1 It is the XRD pattern of the ...

Embodiment 2

[0036] Taking Cu@C nanocables loaded with noble metal Pt as a catalyst as an example, the noble metal loading is 20% for illustration.

[0037] Take 0.51g copper chloride and 13g glucose (the molar ratio is 1:20, including 0.0037mol copper chloride and 0.074mol glucose), add 35mL deionized water, stir evenly, transfer to a 50mL polytetrafluoroethylene reactor, and React at 160°C for 36 hours, wash with deionized water several times after cooling to room temperature, and dry in vacuum;

[0038] Put the product into a tubular atmosphere furnace and calcined under the protection of nitrogen at a temperature of 700°C. Add the calcined product to 100 mL of sodium hydroxide solution with a molar concentration of 2 mol / L, and heat to reflux in a boiling water bath for 3 hours. , after cooling down to room temperature, washed with deionized water until neutral, dried and collected to obtain Cu@C nanocable carrier.

[0039]Take 40mg of Cu@C nanocable carrier and 100mg of sodium oxalat...

Embodiment 3

[0042] Taking Zn@C nanocables loaded with noble metal Pt as a catalyst as an example, the noble metal loading is 5% for illustration.

[0043] Take 1g of zinc sulfate and 1.7mL of ethylene glycol (the molar ratio is 1:5, of which zinc sulfate is 0.0062mol and ethylene glycol is 0.031mol), add it to 35mL of ethylene glycol, stir well and transfer to 50mL polytetrafluoroethylene for reaction In the kettle, react at 100°C for 48h, cool to room temperature, wash with deionized water and ethanol several times, and dry in vacuum;

[0044] Put the product into a tubular atmosphere furnace and calcinate under the protection of nitrogen. The calcining temperature is 500 ° C. Add the calcined product to 200 mL of ammonia solution with a molar concentration of 1 mol / L, heat and reflux in a boiling water bath for 1 hour, and drop to After reaching room temperature, it was washed with deionized water to neutrality, and collected after drying to obtain Zn@C nano-cable carrier.

[0045] Tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com