Minimally invasive repair gel with rana chensinensis skin polypeptide

The technology of Rana wood and gel is applied in the field of minimally invasive repairing gel containing Rana Rana skin polypeptide and its preparation field, and can solve the problems of no public preparation method, unfavorable human skin absorption, excessive molecular weight of Rana Rana skin antibacterial peptide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

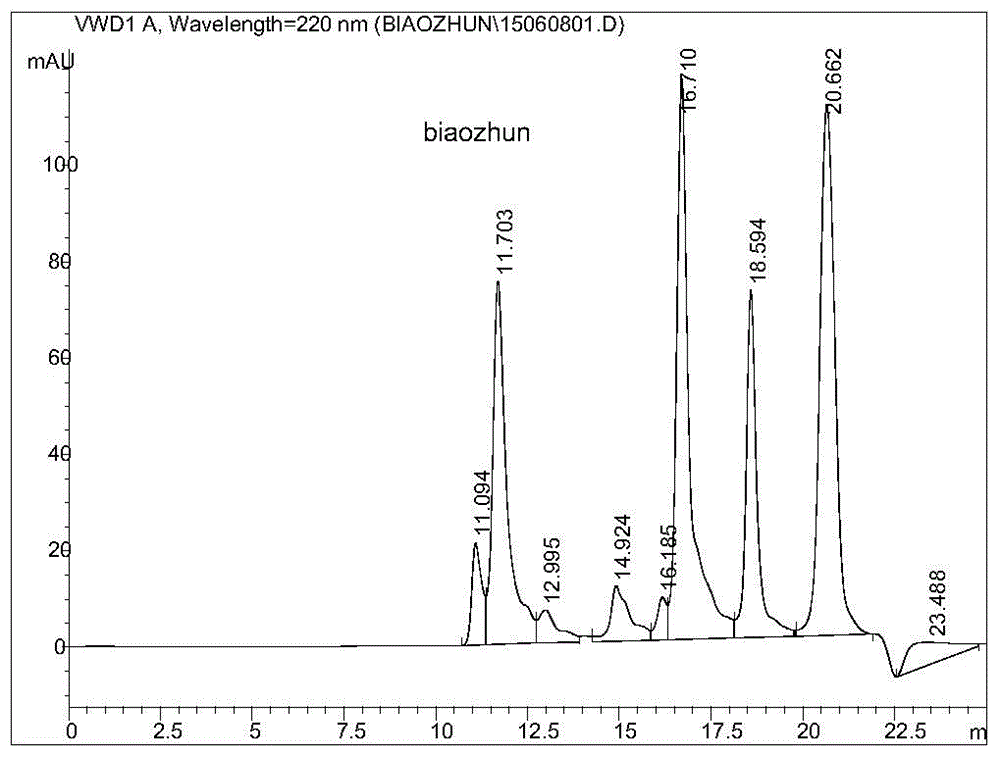

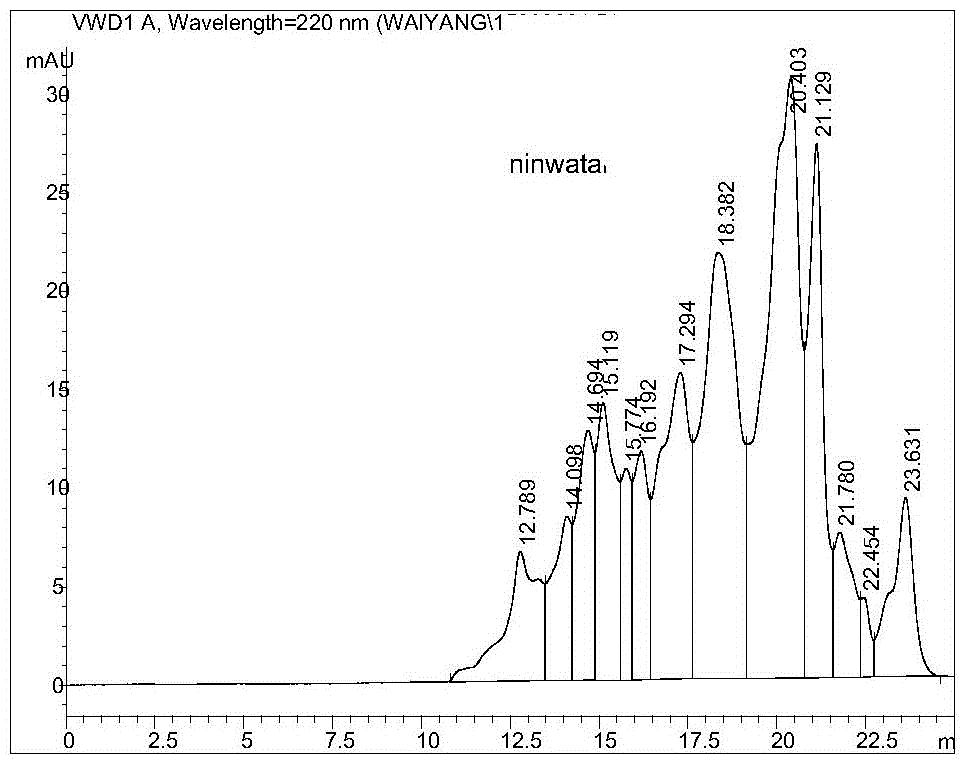

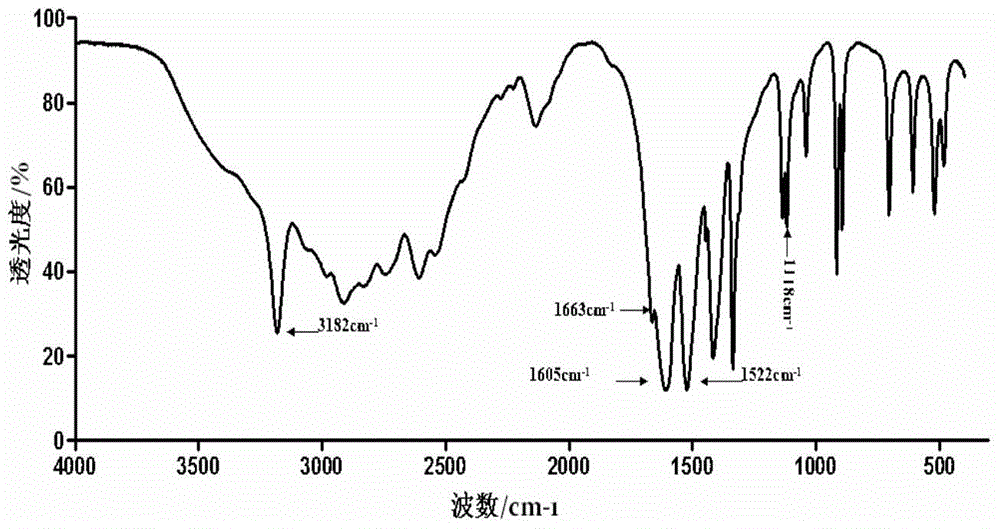

[0066](1) Wash the freshly stripped Rana Rana residue and peel off the skin, take 1000g of Rana Rana skin, mince the Rana Rana skin with a colloid mill, add 5000ml of distilled water to make a homogenate, add 10g of enzyme activity to 100000U / g neutral proteinase K, after enzymatic hydrolysis at 55°C for 4 hours, first filter with a 100-1000 mesh filter cloth, then pass through an ultrafiltration membrane with a molecular weight cut-off of 100kDa and an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and then pass through an ultrafiltration membrane with a molecular weight cut-off of 10kDa 300Da nanofiltration membrane filtration, using the absorbance value at 220nm wavelength to monitor the peptide concentration (12 ~ 20mg / ml) in the retentate, when the peptide concentration is 18.33mg / ml, get 1200ml retentate, add 48g Glycine was freeze-dried to obtain 70 g of Rana skin polypeptide freeze-dried powder. The polypeptide content in the Rana skin freeze-dried ...

Embodiment 2

[0071] (1) Wash the freshly stripped Rana Rana residue and peel off the skin, take 500g of Rana Rana skin, mince the Rana Rana skin with a colloid mill, add 3750ml of distilled water to make a homogenate, add 5g of enzyme activity to 100000U / g Neutral proteinase K, after enzymatic hydrolysis at 60°C for 3 hours, first filtered through a 100-1000 mesh filter cloth and then filtered through an ultrafiltration membrane with a molecular weight cut-off of 100kDa and an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and then filtered through an ultrafiltration membrane with a molecular weight cut-off of 300Da Nanofiltration membrane filtration, using the absorbance value at 220nm wavelength to monitor the polypeptide concentration (12-20mg / ml) in the retentate, when the polypeptide concentration is 14.17mg / ml, get 1200ml retentate, add 48g glycine to the retentate , after freeze-drying, 65 g of Rana skin polypeptide freeze-dried powder was obtained. The polypepti...

Embodiment 3

[0076] (1) Wash the freshly stripped Rana Rana residue and peel off the skin, take 250g Rana Rana skin, grind the Rana Rana skin with a colloid mill, add 2500ml distilled water to make a homogenate, add 2.5g of enzyme activity to 100000U / g of neutral proteinase K, after enzymatic hydrolysis at 65°C for 2 hours, first filter through a 100-1000 mesh filter cloth, then pass through an ultrafiltration membrane with a molecular weight cut-off of 100kDa and an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and then pass through a molecular weight cut-off For 300Da nanofiltration membrane filtration, use the absorbance value at 220nm wavelength to monitor the peptide concentration (12~20mg / ml) in the retentate liquid, when the peptide concentration is 12.00mg / ml, get 500ml retentate liquid, add to the retentate liquid 20g of glycine was freeze-dried to obtain 26g of Rana skin polypeptide freeze-dried powder. The polypeptide content in Rana skin freeze-dried powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com