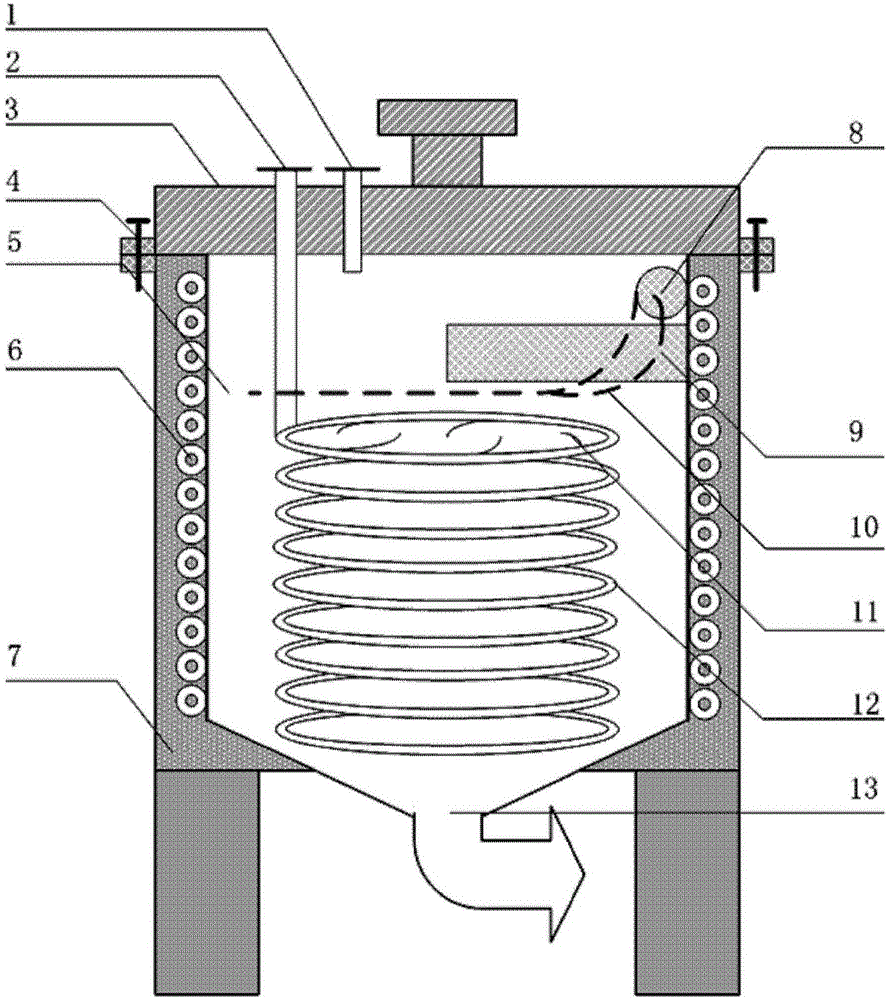

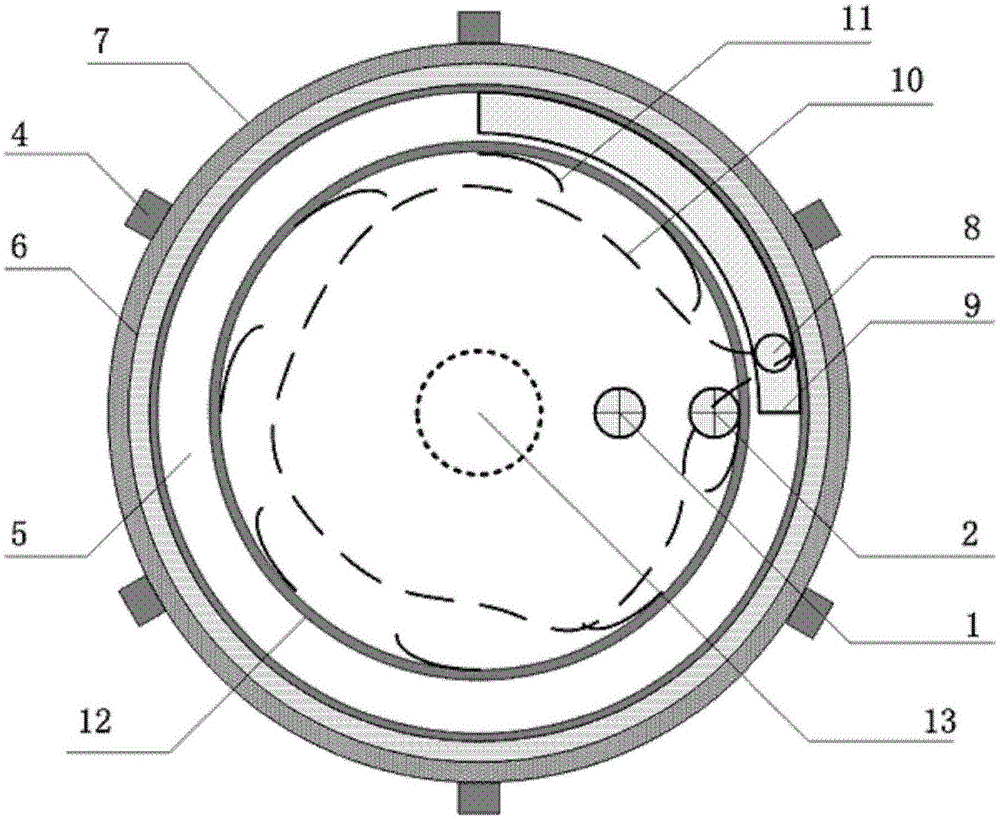

Homogenization and deoiling integrated steam self-rotation damp-heat pretreatment device and pretreatment method

A pretreatment device and pretreatment technology are applied in the field of solid waste recycling, which can solve the problems of low moisture content, low heat and mass transfer efficiency, and high temperature of kitchen waste, so as to improve the service life of equipment and improve heat transfer performance. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention can release the animal fat of the kitchen waste to form floating oil, extract the floating oil while increasing the gas production, and prepare biodiesel; the present invention uses high-temperature steam to replenish water and heat the kitchen waste, which not only can Avoid the problem that the equipment cannot run stably for a long time caused by the aging of the stirring paddle too quickly, and can avoid the phenomenon of excessive water loss caused by high temperature in the process of wet heat pretreatment of kitchen waste, and the present invention uses high temperature steam As the only heat source, it has the advantages of high heat and mass transfer efficiency compared with traditional humid heat equipment using oil bath heating, and the effect of homogenization and oil removal is remarkable. It is non-toxic and harmless and does not produce secondary pollution, ensuring the homogenization of kitchen waste. It can be effectively carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com