Lithium battery SiCO-Si gradient thin film electrode system and preparing method thereof

A thin-film electrode and lithium battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of reducing reversible capacity, reducing the quality of electrode active materials and lithium storage capacity, etc., achieving simple and fast process, excellent battery life Chemical properties, composition controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

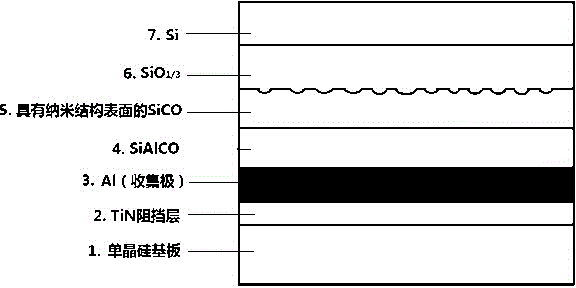

[0032] Example. A lithium battery SiCO-Si gradient thin film electrode system, constituted as figure 1 As shown, a single crystal silicon substrate 1 is included, and a TiN barrier layer 2, an Al thin film layer 3, a SiAlCO thin film layer 4, a SiCO thin film layer 5, a SiO 1 / 3 Thin film layer 6 and Si thin film layer 7.

[0033] The thickness of the TiN barrier layer is 45-55nm (optimally 50nm).

[0034] The thickness of the Al thin film layer is 190-210nm (optimum is 200nm).

[0035] The thickness of the SiAlCO film layer is 45-55nm (optimally 50nm).

[0036] The SiCO film layer, SiO 1 / 3 The thin film layer and the Si thin film layer have the same thickness, both of which are 190-210nm (optimally 200nm).

[0037] According to the preparation method of the above-mentioned lithium batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com