Submarine pipeline flange underwater abutting joint installation method

A submarine pipeline and underwater docking technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large safety hazards in the fixed facilities of divers' platforms, difficulty in adjusting flange angles and pipeline distances, Inconsistencies in stress and deformation of flange gaskets, etc., to achieve the effect of shortening underwater operation time, reducing underwater operation time, and improving underwater operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

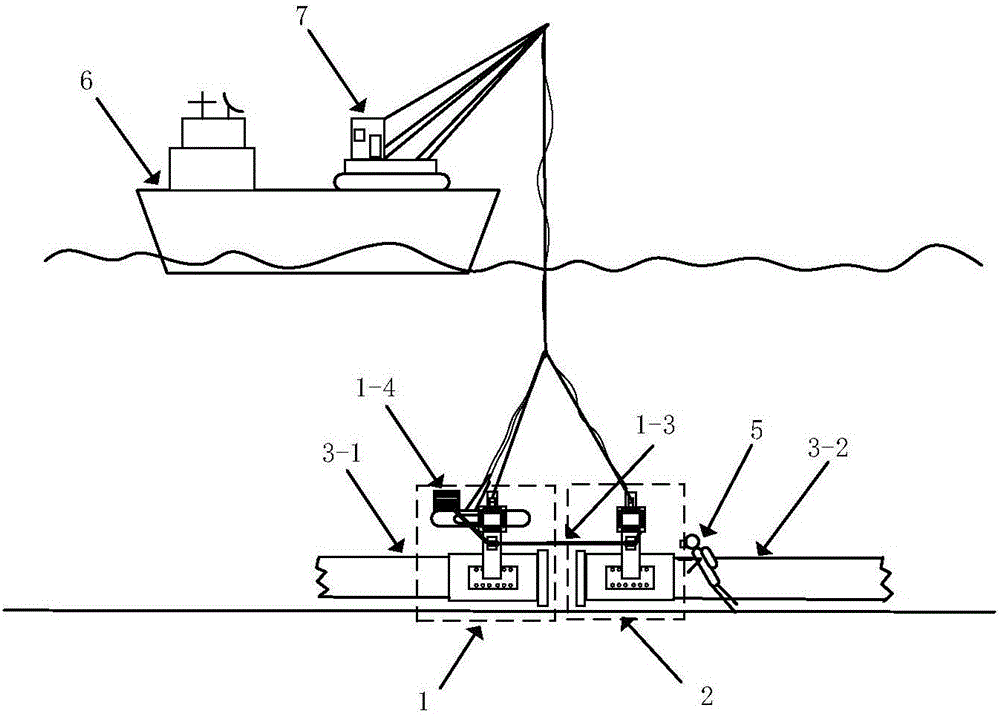

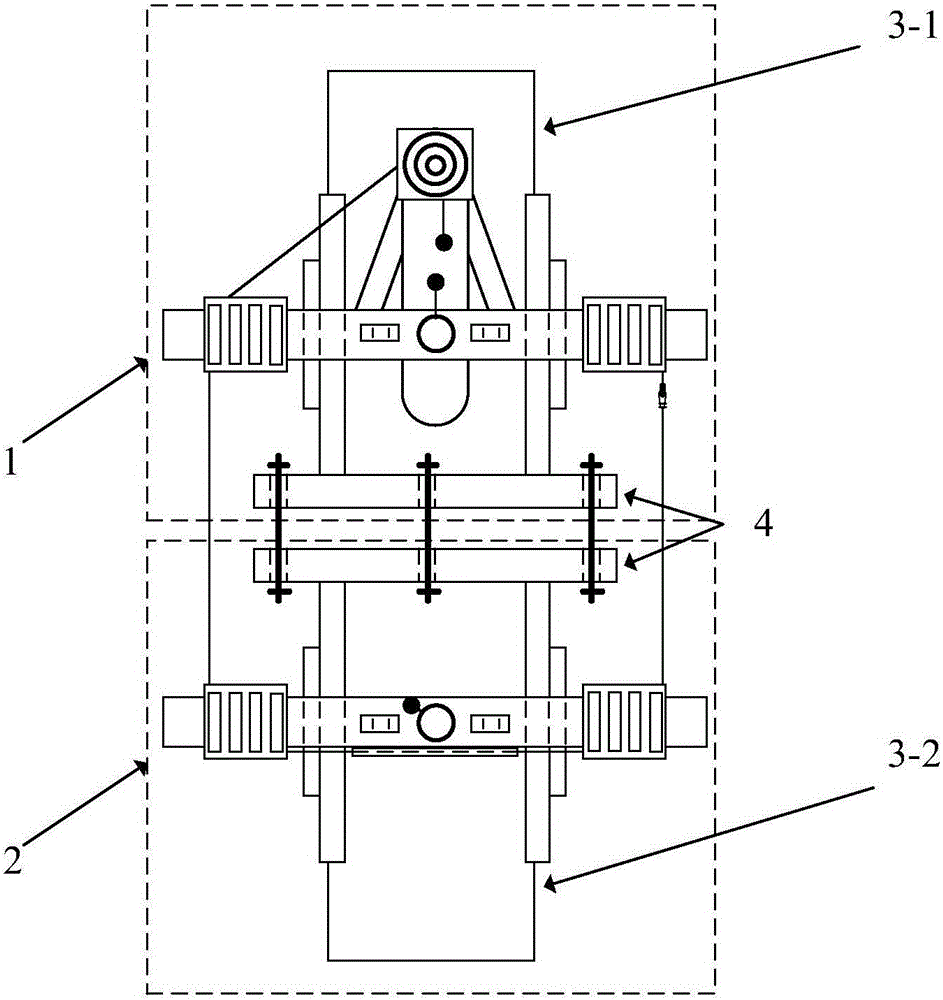

[0024] see Figure 1 to Figure 9 , a submarine pipeline flange underwater butt joint installation method, the joint ends of the submarine pipeline A3-1 and the submarine pipeline B3-2 to be docked have been welded to the flange 4, and the following steps are used to carry out the submarine pipeline A3-1 and the submarine pipeline B3 -2 flange butt joint:

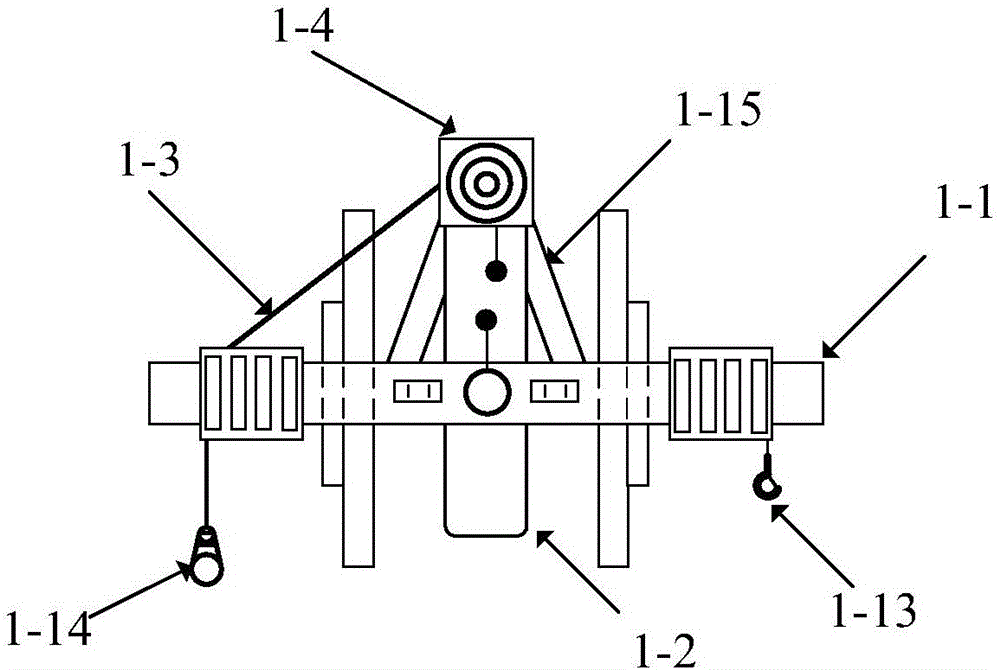

[0025]1) The diver 5 directs the crane 7 on the support ship 6 to lower the main flange connection device 1 to the butt joint end of the submarine pipeline A3-1; the main flange connection device 1 includes a beam I1-1 and a The fixed vertical beam 1-2, the steel wire rope 1-3 and the reel and its drive motor 1-4, the steel wire rope 1-3 is wound on the reel, and the reel and its drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com