Preparation technology of tert-butyl acrylate

A technology for the preparation of tert-butyl acrylate, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low esterification rate, achieve environmental protection, simple process, and raw material utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

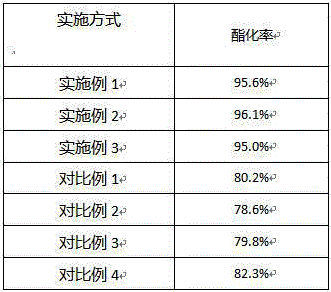

Embodiment 1

[0013] Acrylic acid and isobutylene with a molar ratio of 1.0:1.0, together with an acidic catalyst and a polymerization inhibitor, were esterified at a temperature of 40°C and a reaction pressure of 1.0 MPa at a volume space velocity of isobutylene of 0.5 / h to synthesize tert-butyl acrylate.

[0014] Described polymerization inhibitor is tert-butyl catechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine, and the weight ratio of the above-mentioned 4 kinds of polymerization inhibitors is 1:3:2 : 7; the acidic catalyst is a strongly acidic cation exchange resin.

Embodiment 2

[0016] Acrylic acid and isobutylene with a molar ratio of 5.0:1.0, together with an acid catalyst and a polymerization inhibitor, were esterified at a temperature of 120°C and a reaction pressure of 5.0 MPa at a volume space velocity of isobutylene of 5.0 / h to synthesize tert-butyl acrylate.

[0017] Described polymerization inhibitor is tert-butyl catechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine, and the weight ratio of the above-mentioned 4 kinds of polymerization inhibitors is 1:3:2 : 7; the acidic catalyst is a strongly acidic cation exchange resin.

Embodiment 3

[0019] Acrylic acid and isobutylene with a molar ratio of 3.0:1.0, together with an acidic catalyst and a polymerization inhibitor, were esterified at a temperature of 80°C and a reaction pressure of 3.0 MPa at a volume space velocity of isobutylene of 2.0 / h to synthesize tert-butyl acrylate.

[0020] Described polymerization inhibitor is tert-butyl catechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine, and the weight ratio of the above-mentioned 4 kinds of polymerization inhibitors is 1:3:2 : 7; the acidic catalyst is a strongly acidic cation exchange resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com