Composite absorbable interface screw and preparation method thereof

An interface screw and heterogeneous technology, applied in the field of medical materials, can solve problems such as poor interface compatibility, and achieve the effects of convenient production, no interference with nuclear magnetic effects, and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

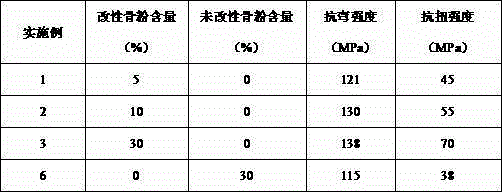

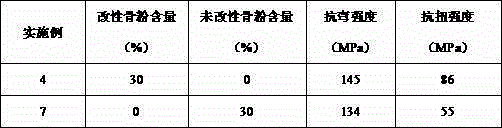

Examples

Embodiment 1

[0032] Step 1, preparation of L-polylactic acid / racemic polylactic acid copolymer

[0033] Add 0.144g of L-lactide, 14.256g of racemic lactide, and 14mg of stannous octoate into the polymerization tube, fill with nitrogen and oxygen, and vacuumize for three times to control the vacuum degree of the polymerization tube to be lower than 1Pa. The polymerization tube was placed in a constant temperature reaction box at 130°C, and reacted for 72 hours to obtain the L-polylactic acid / racemic polylactic acid copolymer.

[0034] In the copolymer prepared in this step, the mass ratio of L-polylactic acid to racemic polylactic acid is 1:99. After measurement, the viscosity-average molecular weight of the copolymer is 50,000, and the intrinsic viscosity is 0.5 dL / g.

[0035] Step 2. Surface modification of xenogeneic deantigenated cortical bone meal

[0036] Dissolve 0.2 g of xenogeneic deantigenated cortical bone powder into 10 ml of stearic acid ethanol solution with a concentration ...

Embodiment 2

[0044] Step 1, preparation of L-polylactic acid / racemic polylactic acid copolymer

[0045] Add 10.08g of L-lactide, 4.32g of racemic lactide, and 14mg of stannous octoate into the polymerization tube, fill with nitrogen and oxygen, and vacuumize for three times to control the vacuum degree of the polymerization tube to be lower than 1Pa. The polymerization tube was placed in a constant temperature reaction box at 130°C, and reacted for 72 hours to obtain the L-polylactic acid / racemic polylactic acid copolymer.

[0046] In the copolymer prepared in this step, the mass ratio of L-polylactic acid to racemic polylactic acid is 70:30. After measurement, the viscosity-average molecular weight of the copolymer is 150,000, and the intrinsic viscosity is 2dL / g.

[0047] Step 2. Surface modification of xenogeneic deantigenated cortical bone meal

[0048] Dissolve 0.2 g of xenogeneic deantigenated cortical bone powder into 20 ml of stearic acid ethanol solution with a concentration of ...

Embodiment 3

[0056] Step 1, preparation of L-polylactic acid / racemic polylactic acid copolymer

[0057] Add 14.256g of L-lactide, 0.144g of racemic lactide, and 14mg of stannous octoate into the polymerization tube, fill with nitrogen to catch up with oxygen, and vacuumize for three times to control the vacuum degree of the polymerization tube to be lower than 1Pa. The polymerization tube was placed in a constant temperature reaction box at 130°C, and reacted for 72 hours to obtain the L-polylactic acid / racemic polylactic acid copolymer.

[0058] In the copolymer prepared in this step, the mass ratio of L-polylactic acid to racemic polylactic acid is 99:1. After measurement, the viscosity-average molecular weight of the copolymer is 500,000, and the intrinsic viscosity is 6.5 dL / g.

[0059] Step 2. Surface modification of xenogeneic deantigenated cortical bone meal

[0060] Dissolve 0.2 g of xenogeneic deantigenated cortical bone powder into 10 ml of stearic acid ethanol solution with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com