Flip LED packaging structure and manufacturing method

A technology of LED packaging and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of restricting the development of LED miniaturization, restricting the application of LEDs, and the large volume of packaged finished products, achieving small package size, high production efficiency, The effect of low packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

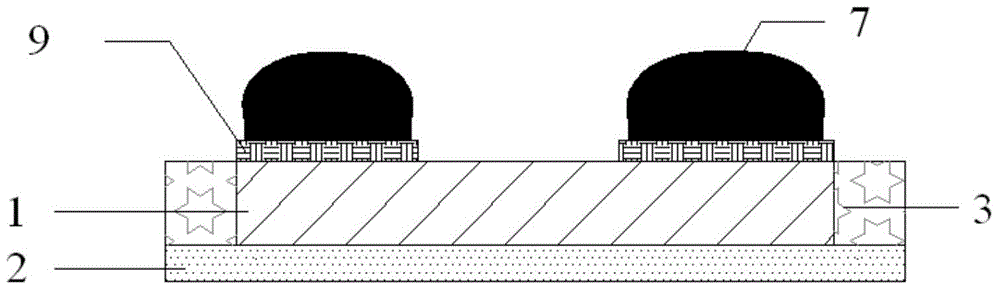

[0083] Such as figure 2 As shown, a flip-chip LED packaging structure includes an LED flip-chip 1, and the LED flip-chip has an electrode surface 101, a light-emitting surface 102 opposite to the electrode surface, and a peripheral side surface 103;

[0084] The electrode surface is not wrapped with an upper surrounding layer, and the exposed electrode 9 of the LED flip chip is provided with a solder bump 7;

[0085] The light-emitting surface is wrapped with a lower surrounding layer, and the lower surrounding layer is a single-layer structure. The single-layer structure is a layer of fluorescent layer 2. The fluorescent layer is used to convert the light emitted by the chip from fluorescent materials to white light. The fluorescent layer can be made of Phosphor powder, or transparent glue mixed with phosphor powder, or a dry film made of fluorescent material.

[0086] Optionally, the single-layer structure can also be a layer of fluorescent glass fiber composite layer 12 ....

Embodiment 2

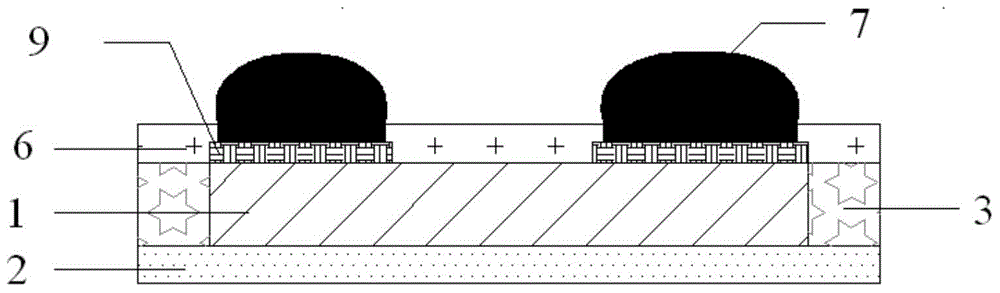

[0091] Such as image 3 As shown, this embodiment 2 includes all the technical features of embodiment 1, the difference is that the electrode surface is wrapped with an upper surrounding layer, the upper surrounding layer is a layer of protective layer 6, and the protective layer is provided with an opening , the opening exposes the electrode 9 of the LED flip chip 1 , and the solder bump 7 is arranged on the electrode. The protective layer can isolate water vapor, air, etc., and avoid corrosion of electrodes or connecting electrode metal materials. The material of the protective layer 6 includes one or more of high molecular polymers such as epoxy resin, silicon oxide, silicon nitride, and plastic packaging materials. kind.

Embodiment 3

[0093] Such as Figure 4 As shown, this embodiment 3 includes all the technical features of embodiment 2, and the difference is that the light-emitting surface is wrapped with a lower surrounding layer, and the lower surrounding layer has a two-layer structure, and the light transmission is strengthened sequentially from the inside to the outside. layer 3 and fluorescent layer 2; the surrounding side is wrapped with a surrounding layer, and the surrounding layer is a two-layer structure, which is the light transmission strengthening layer 3 and the fluorescent layer 2 in sequence from the inside to the outside. The light-transmitting strengthening layer is used to transmit light and increase the mechanical strength of the chip, and the fluorescent layer is used to convert the side light of the chip from fluorescent material to white light; that is, to realize the function of increasing the mechanical strength of the chip while changing the color of the light-emitting surface an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com