Glass Frit Using Glass Powder With Low Melting Point And Crystalline Ceramic Filler With Low Expansion And Paste Comprising The Same

A technology of low melting point glass and glass transition temperature, which is applied in the field of glass frit and paste containing the low melting point glass frit, which can solve the problems of differential adhesion (reduced sealing reliability, poor water resistance, deterioration, etc.) to reduce thermal expansion Coefficient difference, improved sealing reliability, reduced effect of reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Hereinafter, the structure and function of the present invention will be described in more detail through preferred embodiments of the present invention. However, this is only a preferred embodiment of the present invention, and the present invention cannot be construed as being limited thereto in any sense.

[0064] A person of ordinary skill in the art to which the present invention pertains can fully make technical analogies on the contents not described here, and therefore description thereof is omitted.

[0065] 1. Preparation of Glass Frit

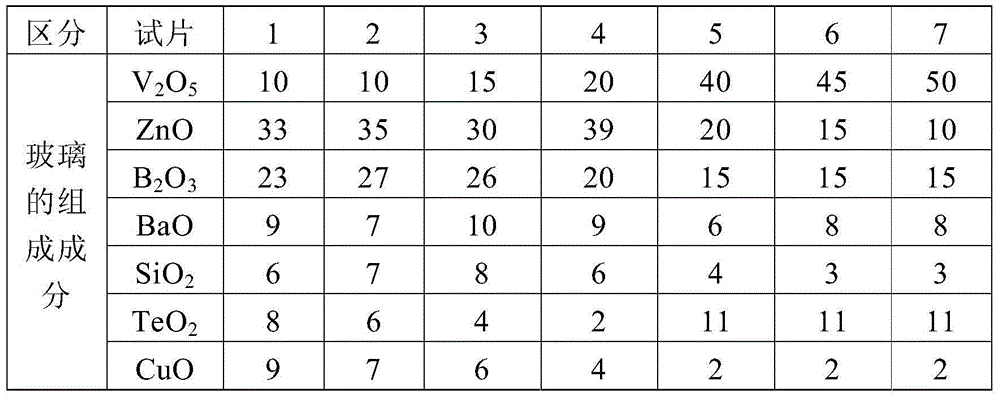

[0066] Glass frit test piece 1 to glass frit test piece 7 having the composition described in Table 1 were prepared.

[0067] In addition, the glass frit was prepared by mixing 40 parts by weight of zirconium tungsten phosphate with respect to 100 parts by weight of the above-mentioned glass frit test piece.

[0068] Table 1 (unit: mole percent)

[0069]

[0070]

[0071] 2. Characteristic evaluation

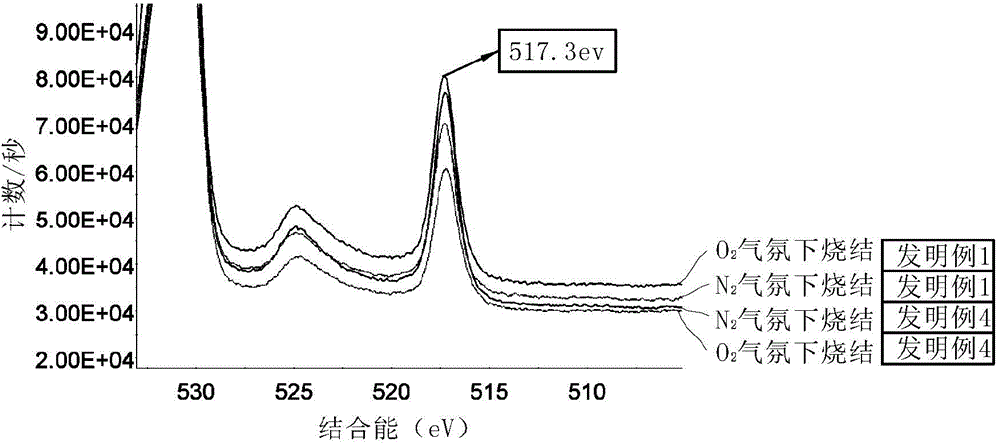

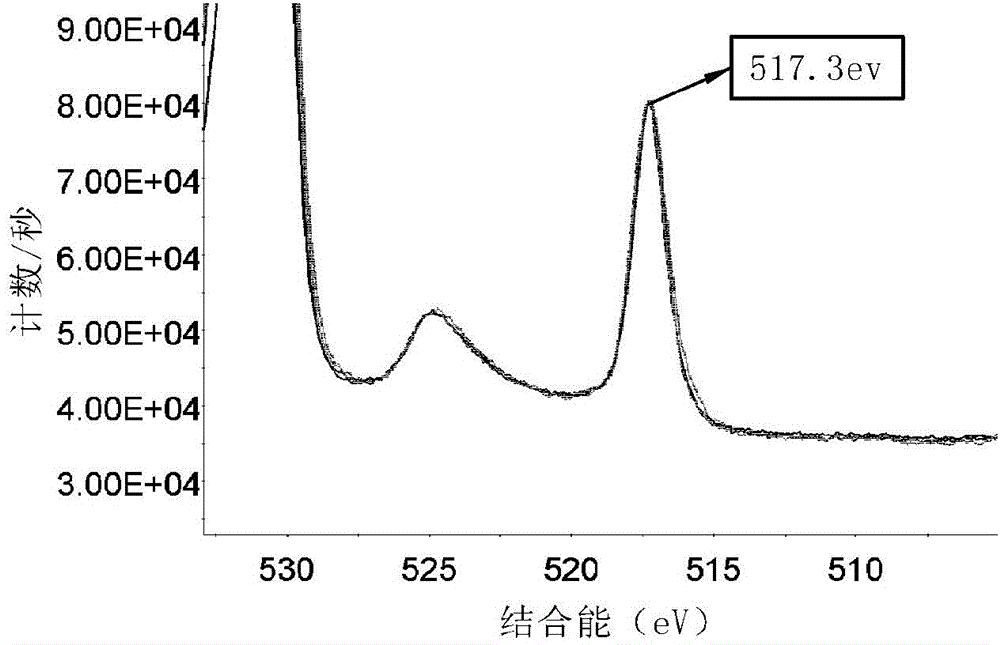

[0072] Glass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com