Ni2P/Al2O3 catalyst and preparation method therefor

A catalyst and carrier technology, applied in the field of supported nickel phosphide solid catalyst and its preparation, can solve the problems of difficult catalyst and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Ce Oxide-Modified Pentacoordinate Al-rich Al 2 o 3 .

[0024] Weigh 12 grams of Al(NO 3 ) 3 9H 2 O was dissolved in 15 milliliters of deionized water to make solution A, then weighed 4 grams of glycine (C 2 h 5 NO 2 ) was dissolved in 15 milliliters of deionized water to make solution B, the two were mixed while stirring, then the pH value of the solution was adjusted to 2-3 by adding dilute nitric acid dropwise, and then 0.347 grams of cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.2 g of polyethylene glycol. After the solution was fully mixed, it was transferred into a crucible, and left to age at room temperature for 12 hours. Afterwards, the crucible was dried in an oven at 120°C until it was in a colloidal state, and then the crucible was placed in a muffle furnace and heated to 750°C at a rate of 5°C / min, and fired for 4 hours to obtain Ce oxide-modified Al 2 o 3 , denoted as Ce-Al 2 o 3 , where Ce oxides (as CeO 2 The content of mass per...

Embodiment 2

[0026] Al(NO 3 ) 3 Preparation of Al after reaction with citric acid 2 o 3

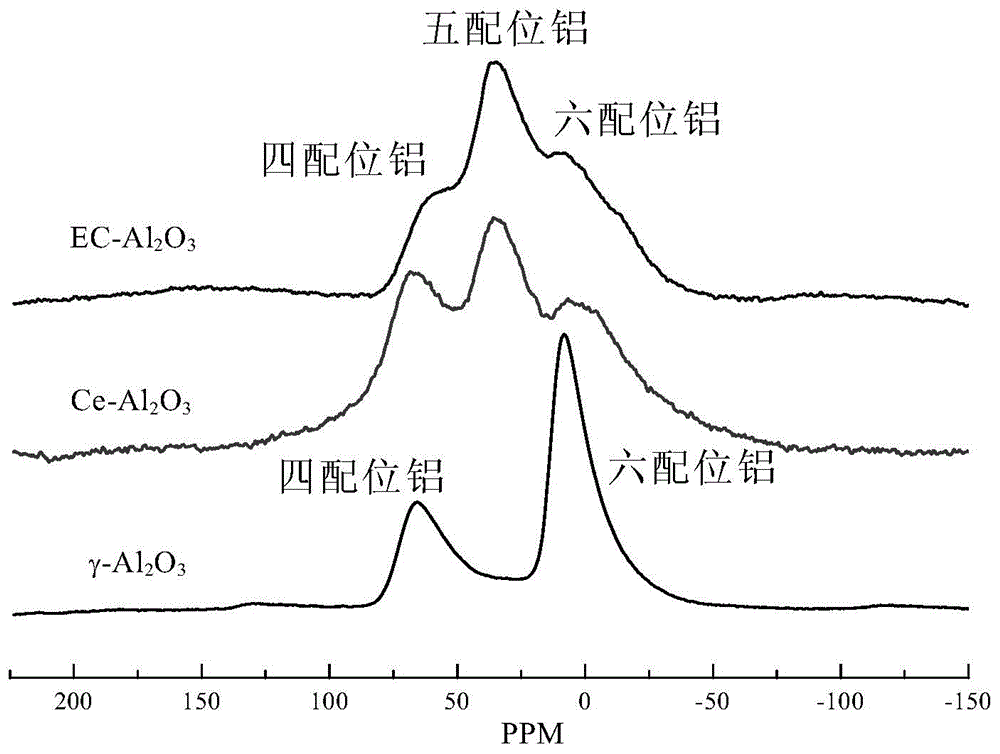

[0027] Al was prepared according to the method disclosed in the literature 2 o 3 (Colloids and Surfaces A: Physicochem. Eng. Aspects, 2010, 371:126-130). Weigh 3.75 grams of Al(NO 3 ) 3 9H 2 O was dissolved in 20 ml of ethanol to make solution A, and then 0.84 g of citric acid was weighed and dissolved in solution A, then 1 g of P123 was added under vigorous stirring, stirred in a water bath at 60°C for 12 hours, and then placed in an oven at 60 ℃ to dry to a transparent solid state, and then aged at room temperature for 96 hours, transferred to a crucible and heated to 400-800 ℃ for 6 hours in a muffle furnace, recorded as EC-Al 2 o 3 . Combined with references (J.Colloid Interf.Sci.,2003,261:320-324; Acta Catalytica Sinica,2010,31:528-534), by 27 Al MAS NMR spectrum ( figure 1 ), it can be seen that in EC-Al 2 o 3 Among them, the intensity of the five-coordinated aluminum peak is the ...

Embodiment 3

[0029] Starting from nickel phosphate precursor, the supported nickel phosphide catalyst was prepared by hydrogen temperature programmed reduction method.

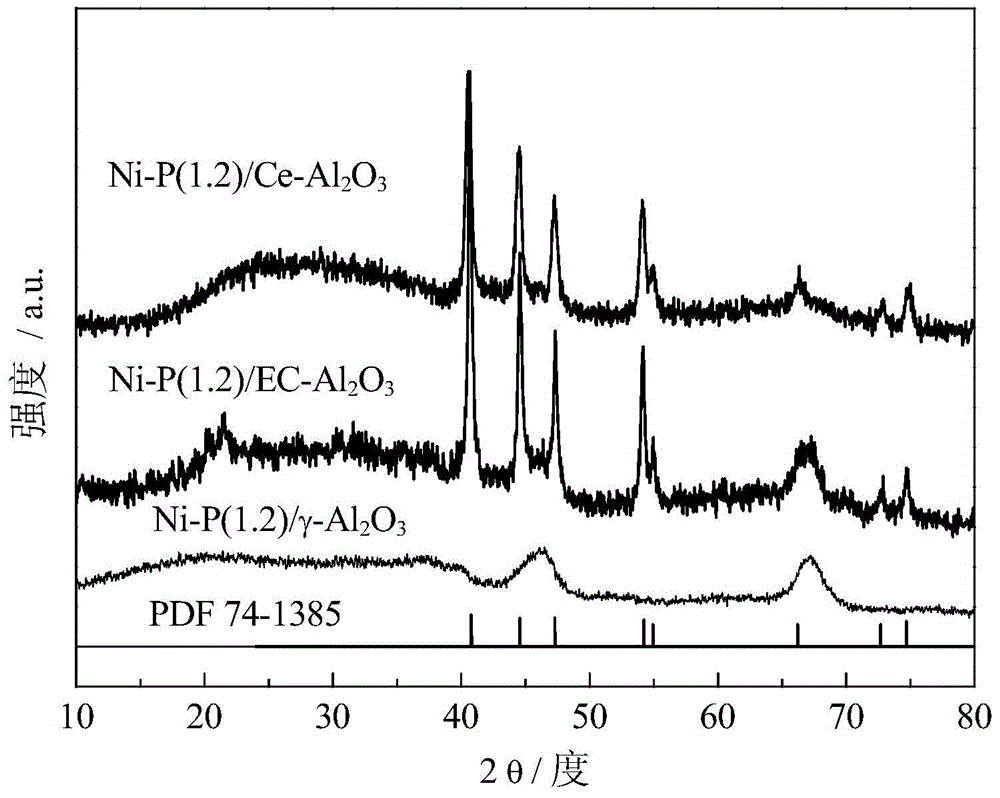

[0030] Phosphate precursors of supported nickel phosphide catalysts were prepared by a stepwise impregnation method. First weigh 1.12 grams of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) be dissolved in 2 milliliters of deionized water and make impregnating liquid, then slowly add dropwise to the gamma-Al of 1.8 grams in above-mentioned impregnating liquid 2 o 3 or Ce-Al 2 o 3 or EC-Al 2 o 3 , aged at room temperature for 8 hours, and then dried in an oven at 120°C to prepare precursor A. Then weigh 0.613 grams of diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was dissolved in 3 ml of deionized water to make an impregnating solution, which was slowly added dropwise to the precursor A, left to age at room temperature for 8 hours, and dried at 120°C to prepare the precursor B. Then the precursor B was calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com